INTRTODUCTION

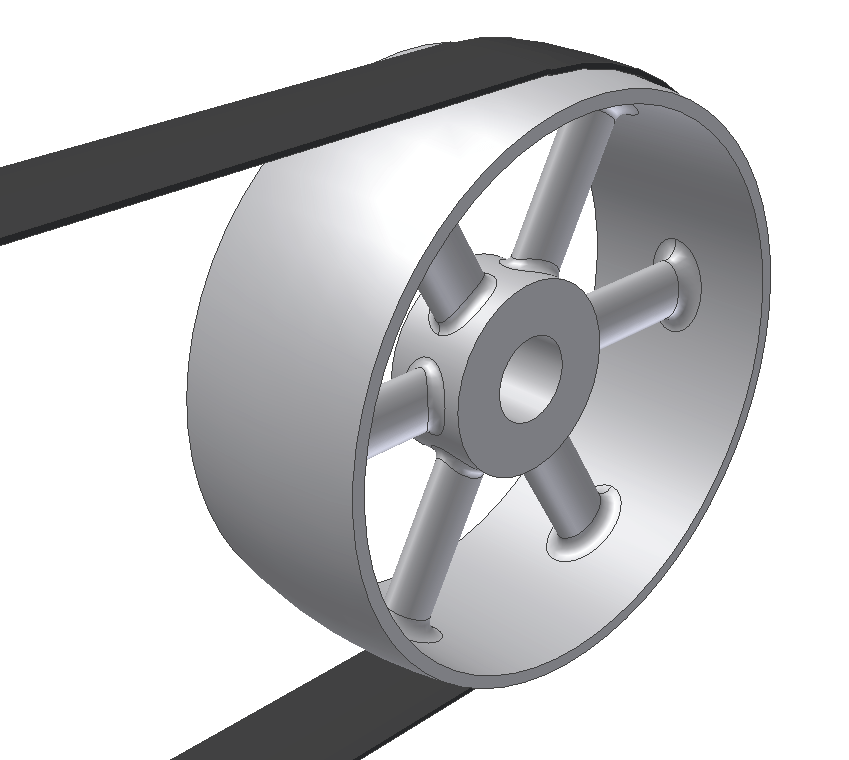

Flat Belts are one type of flexible connectors for transmitting power from one pulley to another pulley. Whose center distance is approx. 5-15m

Characteristics Of Belt:

Types Of Flat Belt Drives:

1. Open belt drive

2. Cross belt drive

3. Quarter turn drive

4. Belt drive with idler pulley

5. Belt drive with many pulleys

Design Of Flat Belts

1. Using fundamental formula

2. Using Manufactures catalogues

Fundamental Formula:

3. Ratio of driving tensions

4. Power Transmitted by belt

Manufactures Catalogues

1. How much power to be transmitted

2. What may be the power transmitting capacity

For determining the design power and belt rating, we must consider certain factors like service, arc of contact and so on.

i. Arc of contact

ii. Load rating

The load ratings have been developed for 180° of arc of contact 10m/s belt speed per mm width.

iii. Length of belt

iv. Belt tensions

1. Belt of 3 plies – 1.5% of L

2. Belt of 4,5,6 plies – 1% of L

3. Belt of 8 plies – 0.5% of L

v. Pulley width

Generally the pulleys should be slightly wider than belt width.

Power Transmission

Belts are the cheapest utility for power transmission between shafts that may not be axially aligned. Power transmission is achieved by specially designed belts and pulleys. The demands on a belt drive transmission system are large and this has led to many variations on the theme. They run smoothly and with little noise, and cushion motor and bearings against load changes, albeit with less strength than gears or chains. However, improvements in belt engineering allow use of belts in systems that only formerly allowed chains or gears. Power transmitted between a belt and a pulley is expressed as the product of difference of tension and belt velocity

where, T1 and T2 are tensions in the tight side and slack side of the belt respectively. They are related as:

Design Procedure

1. From the given conditions like power, type of working conditions, diameters of pulleys, speed ratio etc, determine maximum power

Design power = rated power x service factor x arc of contact factor

Select service factor based on nature of load and applications from PSG data book

2. Decide the type of belt

3. Then calculate the belt rating

4. Find the required width by design power by belt capacity and adopt the standard available

5. Determine the length of belt based on type of drive and reduce certain amount length 6. Find out the pulley dimension and draw the arrangement of belt drive.