Magnetic Flux Leakage (MFL) is a method of non-destructive testing that is used to detect corrosion and pitting in metallic pipelines. MFL tools scan the full circumference and length of a pipeline, providing high-resolution information on pipe wall condition. MFL scans the pipe through linings to measure remaining wall thickness and provide depth and location of metal wall loss caused by corrosion, pitting or other deterioration mechanisms. Providing the high-resolution data only a technology such as MFL can yield, comprehensive evaluation using structural models incorporating pipe industry standards can be performed to ensure structural performance criteria are being met.

THE PRINCIPLE

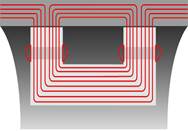

The basic principle behind MFL involves magnetizing a ferrous metal object to saturation level with a powerful magnetic field. Where the object has no flaws, the magnetic flux will remain undisturbed.

High magnetization levels are required to differentiate corrosion from other pipeline features such as hard spots, stress and strain variations and to minimize the effects of remanent magnetization and velocity.

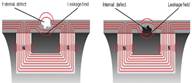

Where there is internal or external metal loss, the magnetic flux leaks from the object.

In the MFL testing device, a magnetic sensor is placed between the poles of a magnet yoke to record the leakage field by Hall-effect sensors. Eddy current sensors integrated in the magnetic flux sensors are used to improve the differentiation between internal and external defects.

APPLICATIONS

MFL is used to detect metal loss defects (such as corrosion) in a wide range of settings.