1) Most condensers used in steam power plants operate at pressures well below the atmospheric pressure to maximize cycle thermal efficiency, and operating at such low pressures raises the possibility of air (a non-condensable gas) leaking into the condensers.

2) Even small amounts of a non-condensable gas in the vapor cause significant drops in heat transfer coefficient during condensation. For example, the presence of less than 1 percent (by mass) of air in steam can reduce the condensation heat transfer coefficient by more than half.

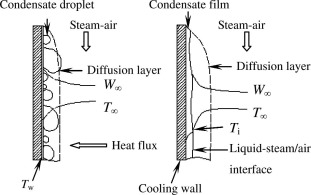

3) When the vapor mixed with a non-condensable gas condenses, only the non-condensable gas remains in the vicinity of the surface. This gas layer acts as a barrier between the vapor and the surface, and makes it difficult for the vapor to reach the surface.