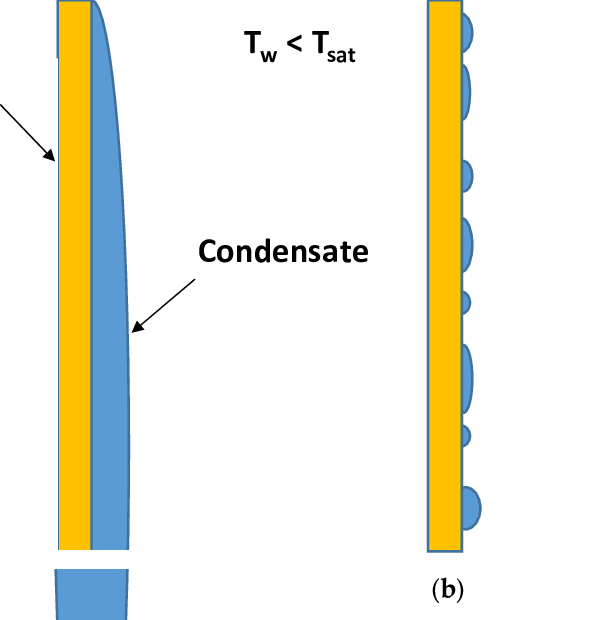

1) Dropwise condensation, characterized by countless droplets of varying diameters on the condensing surface instead of a continuous liquid film, is one of the most effective mechanisms of heat transfer, and extremely large heat transfer coefficients can be achieved with this mechanism

2) In dropwise condensation, the small droplets that form at the nucleation sites on the surface grow as a result of continued condensation, coalesce into large droplets, and slide down when they reach a certain size, clearing the surface and exposing it to vapor.

3) There is no liquid film in this case to resist heat transfer.

4) Heat transfer coefficients can be achieved that are more than 10 times larger than those associated with film condensation.

5) The challenge in dropwise condensation is not to achieve it, but rather, to sustain it for prolonged periods of time.

6) Dropwise condensation is achieved by adding a promoting chemical into the vapor, treating the surface with a promoter chemical, or coating the surface with a polymer such as Teflon or a noble metal such as gold, silver, rhodium, palladium, or platinum.

7) The very high heat transfer coefficients achievable with dropwise condensation are of little significance if the material of the condensing surface is not a good conductor like copper or if the thermal resistance on the other side of the surface is too large.