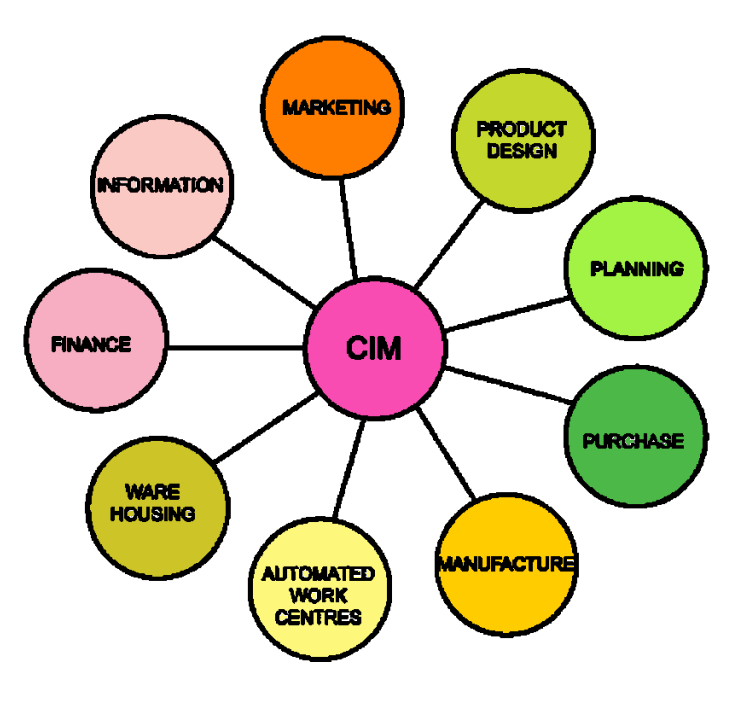

Nine major elements of a CIM system are in Figure 2 they are,

· Marketing

· Product Design

· Planning

· Purchase

· Manufacturing Engineering

· Factory Automation Hardware

· Warehousing

· Logistics and Supply Chain Management

· Finance

· Information Management

Figure 2 Major elements of CIM systems

i. Marketing:

The need for a product is identified by the marketing division. The specifications of the product, the projection of manufacturing quantities and the strategy for marketing the product are also decided by the marketing department. Marketing also works out the manufacturing costs to assess the economic viability of the product.

ii. Product Design:

The design department of the company establishes the initial database for production of a proposed product. In a CIM system this is accomplished through activities such as geometric modelling and computer aided design while considering the product requirements and concepts generated by the creativity of the design engineer. Configuration management is an important activity in many designs. Complex designs are usually carried out by several teams working simultaneously, located often in different parts of the world. The design process is constrained by the costs that will be incurred in actual production and by the capabilities of the available production equipment and processes. The design process creates the database required to manufacture the part.

iii. Planning:

The planning department takes the database established by the design department and enriches it with production data and information to produce a plan for the production of the product. Planning involves several subsystems dealing with materials, facility, process, tools, manpower, capacity, scheduling, outsourcing, assembly, inspection, logistics etc. In a CIM system, this planning process should be constrained by the production costs and by the production equipment and process capability, in order to generate an optimized plan.

iv. Purchase:

The purchase departments is responsible for placing the purchase orders and follow up, ensure quality in the production process of the vendor, receive the items, arrange for inspection and supply the items to the stores or arrange timely delivery depending on the production schedule for eventual supply to manufacture and assembly.

v. Manufacturing Engineering:

Manufacturing Engineering is the activity of carrying out the production of the product, involving further enrichment of the database with performance data and information about the production equipment and processes. In CIM, this requires activities like CNC programming, simulation and computer aided scheduling of the production activity. This should include online dynamic scheduling and control based on the real time performance of the equipment and processes to assure continuous production activity. Often, the need to meet fluctuating market demand requires the manufacturing system flexible and agile.

vi. Factory Automation Hardware:

Factory automation equipment further enriches the database with equipment and process data, resident either in the operator or the equipment to carry out the production process. In CIM system this consists of computer-controlled process machinery such as CNC machine tools, flexible manufacturing systems (FMS), Computer controlled robots, material handling systems, computer-controlled assembly systems, flexibly automated inspection systems and so on.

vii. Warehousing:

Warehousing is the function involving storage and retrieval of raw materials, components, finished goods as well as shipment of items. In today’s complex outsourcing scenario and the need for just-in-time supply of components and subsystems, logistics and supply chain management assume great importance.

viii. Finance:

Finance deals with the resources pertaining to money. Planning of investment, working capital, and cash flow control, realization of receipts, accounting and allocation of funds are the major tasks of the finance departments.

ix. Information Management:

Information Management is perhaps one of the crucial tasks in CIM. This involves master production scheduling, database management, communication, manufacturing systems integration and management information systems