Joel Goldhar, Dean, Illinois Institute of Technology gives CIM as a computer system in which the peripherals are robots, machine tools and other processing equipment.

Dan Appleton, President, DACOM, Inc. defines CIM is a management philosophy, not a turnkey product.

Jack Conaway, CIM Marketing manager, DEC, defines CIM is nothing but a data management and networking problem.

The computer and automated systems association of the society of Manufacturing Engineers (CASA/SEM) defines CIM is the integration of total manufacturing enterprise by using integrated systems and data communication coupled with new managerial philosophies that improve organizational and personnel efficiency.

CIM is recognized as Islands of Automation. They are

1. CAD/CAM/CAE/GT

2. Manufacturing Planning and Control.

3. Factory Automation

4. General Business Management

CASA/SME’s CIM Wheel is as shown in figure

Fig CASA/SME CIM Wheel

Conceptual model of manufacturing

The computer has had and continues to have a dramatic impact on the development of production automation technologies. Nearly all modern production systems are implemented today using computer systems. The term computer integrated manufacturing (CIM) has been coined to denote the pervasive use of computers to design the products, plan the production, control the operations, and perform the various business-related functions needed in a manufacturing firm. CAD/CAM (computer-aided design and computer-aided manufacturing) is another term that is used almost synonymously with CIM.

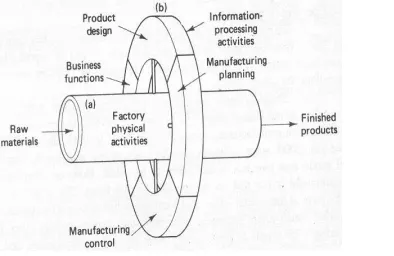

Let us attempt to define the relationship between automation and CIM by developing a conceptual model of manufacturing. In a manufacturing firm, the physical activities related to production that take place in the factory can be distinguished from the information-processing activities, such as product design and production planning, that usually occur in an office environment. The physical activities include all of the manufacturing processing, assembly, material handling, and inspections that are performed on the product. These operations come in direct contact with the product during manufacture. They touch the product. The relationship between the physical activities and the information processing activities in our model is depicted in Figure 5. Raw materials flow in one end of the factory and finished products flow out the other end. The physical activities (processing, handling, etc.) take place inside the factory. The information-processing functions form a ring that surrounds the factory, providing the data and knowledge required to produce the product successfully. These information-processing functions include (1) certain business activities (e.g., marketing and sales, order entry, customer billing, etc.), (2) product design, (3) manufacturing planning, and (4) manufacturing control. These four functions form a cycle of events that must accompany the physical production activities, but which do not directly touch the product.

Now consider the difference between automation and CIM. Automation is concerned with the physical activities in manufacturing. Automated production systems are designed to accomplish the processing, assembly, material handling, and inspecting activities with little or no human participation. By comparison, computer integrated manufacturing is

In the figure 5 Model of manufacturing, showing (a] the factory as a processing pipeline where the physical manufacturing activities are performed, and (b) the information-processing activities that support manufacturing as a ring that surrounds the factory concerned more with the information-processing functions that are required to support the production operations. CIM involves the use of computer systems to perform the four types of information-processing functions. Just as automation deals with the physical activities, CIM deals with automating the information-processing activities in manufacturing.