An FEA consulting customer recently asked if CAE Associates could perform a structural analysis of the response of human bone that has undergone a transplant procedure. Before giving a definitive answer, we quickly went through the usual finite element analysis checklist:

● CAD model exists? Check.

● Loading defined? Check.

● Aren’t we finite element analysis experts who can handle anything? Check.

Things were going great until the customer told us that the material response of the bone material is a function of density, and the density is a particular function of stress and time. Not check. No material law that could model this unique response existed in ANSYS.

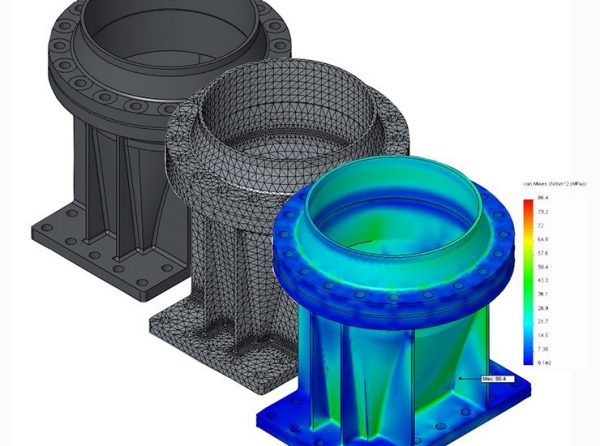

However, not to fear, ANSYS provides the option to allow the user to customize the FEA code to add things like user-defined commands, loadings, element formulations, and of course, material constitutive laws. We are not limited to what the general-purpose codes offer, but can extend these to create our own versions of the code that will do our bidding.

The customization of finite element analysis codes opens the door to almost anything you can imagine. For the above bone modeling problem, a user-created material law was implemented and used to determine bone response after implant to determine post-operative density changes including potential “dead spots” that see little loading and thus will lose density and strength. These results can lead to changes in the implant design to reduce and eliminate these dead spots.

CAE Associates has created and applied user-defined customization to model such features as automatic mesh morphing to model crack propagation, various material models including plasticity, creep and viscoplasticity, defining a new element type used in failure models for theWorld Trade Center, and many other applications.

The one main caveat is that customization requires the boldness to go outside the usual comfort zone of basic analysis procedures, the patience to figure out how customization is implemented in a particular finite element code, and of course some knowledge of finite element theory to understand how the user-defined information will be used within the code.