1)  increases in the flow direction x because of continued condensation at the liquid–vapor interface.

increases in the flow direction x because of continued condensation at the liquid–vapor interface.

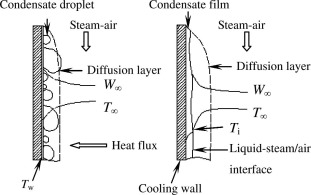

a) Heat in the amount hfg (the latent heat of vaporization) is released during condensation and is transferred through the film to the plate surface at temperature Ts

2) Heat Transfer Correlations for Film Condensation

a) Vertical Plates

i) Assumptions

(1) Both the plate and the vapor are maintained at constant temperatures of Ts and Tsat, respectively, and the temperature across the liquid film varies linearly.

(2) Heat transfer across the liquid film is by pure conduction (no convection currents in the liquid film).

(3) The velocity of the vapor is low (or zero) so that it exerts no dragon the condensate (no viscous shear on the liquid–vapor interface).

(4) The flow of the condensate is laminar and the properties of the liquid are constant.

(5) The acceleration of the condensate layer is negligible

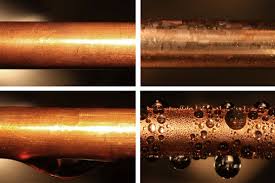

b) Equation for vertical plates can also be used to calculate the average heat transfer coefficient for laminar film condensation on the outer surfaces of vertical tubes provided that the tube diameter is large relative to the thickness of the liquid film.

c) Horizontal Tubes: The average heat transfer coefficient for film condensation on the outer surfaces of a horizontal tube is determined to be

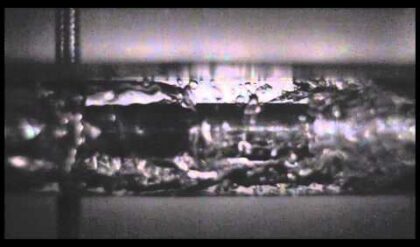

d) Horizontal Tubes: Heat transfer analysis of condensation inside tubes is complicated by the fact that it is strongly influenced by the vapor velocity and the rate of liquid accumulation on the walls of the tubes

Comments are closed.