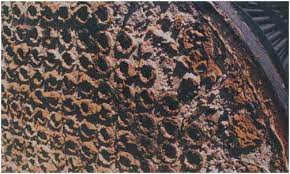

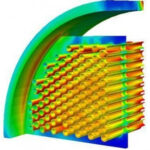

1) The performance of heat exchangers usually deteriorates with time as a result of accumulation of deposits on heat transfer surfaces. The layer of deposits represents additional resistance to heat transfer and causes the rate of heat transfer in a heat exchanger to decrease. The net effect of these accumulations on heat transfer is represented by a fouling factor Rf which is a measure of the thermal resistance introduced by fouling.

2) Types of fouling

a) Precipitation of solid deposits in a fluid on the heat transfer surfaces

b) Corrosion and other chemical fouling

c) Biological fouling – by the growth of algae in warm fluids, can be prevented by chemical treatment.

3) Fouling factor depends on the operating temperature and the velocity of the fluids, as well as the length of service. Fouling increases with increasing temperature and decreasing velocity.

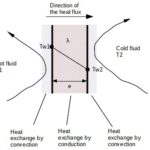

4) The overall heat transfer coefficient relation is valid for clean surfaces and needs to be modified to account for the effects of fouling on both the inner and the outer surfaces of the tube