STEP-1

Received data from customer

Steam output, feedwater inlet

Fuel analysis, boiler type

Power plant heat balance

STEP-2

Boiler Thermal Sizing:

Combustion, efficiency, steam output calculation,

Furnace, Back pass & Cyclone sizing,

Metal temperature calculation,

Emission calculation, Air Heater Calculation, etc.

Iteration with customer/steam turbine back to STEP-1

STEP-3

Pressure part material selection and ASME calculation & Pipe Stress Analysis:

Tubing, pipe manifold, drum and internal piping & external piping

Furnace Sizing, Boiler Circulation

STEP-4

Non Pressure Part selection and calculation/Simulation

Structural steel Design calculation

Pressure part hanger calculation, etc.

Iteration to STEP-3 for pressure part weight and arrangement

STEP-5

From step-2, perform external piping selection:

Material selection, ASME calculation, Pipe Stress Analysis

Pressure Drop Calculation

STEP-6

Create Pressure Part Arrangement

Iteration with Step-3/4/5

STEP-7

Create General Arrangement & Layout

Iteration with Step-3/4/5/6

STEP-8

Create P&ID Drawing

Steam/Water Diagran, Flue Gas Diagram,

Fuel Diagram, Limestone Diagram, Inert Injection Diagram

STEP-9

Create Bill of Material of Structural & Support (Non Pressure Part)

STEP-10

Create Bill of Material of Tubing, Piping (Pressure Part)

STEP-11

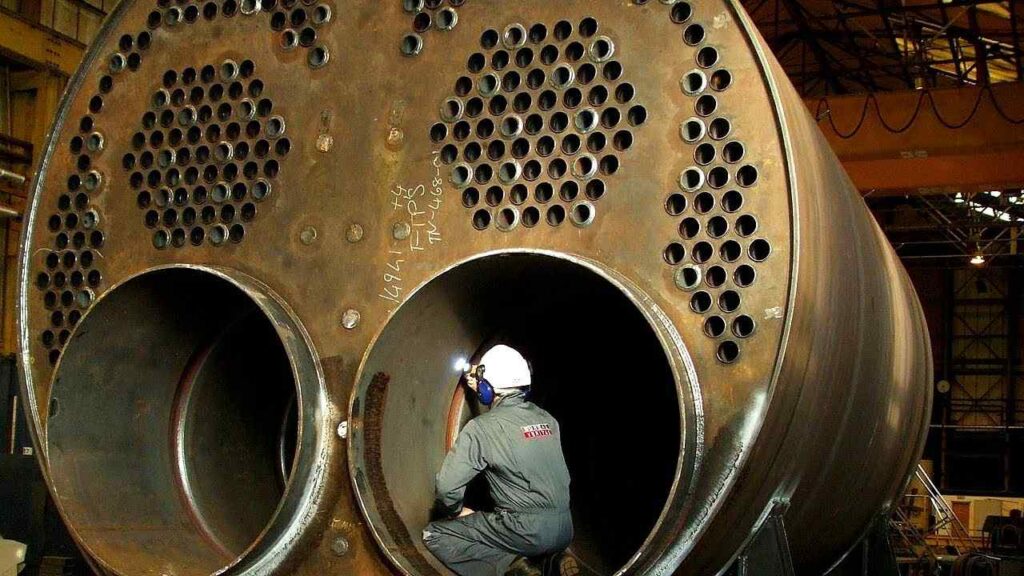

Create Drum Arrangement Drawing,

Drum Internal Drawing, Welding Detail

STEP-12

Create Pressure Part Drawing & Welding Detail:

Evaporator, Furnace wall, superheater section

STEP-13

Create Non Pressure Part Drawing & Welding Detail:

Structural Steel, Casing, Ducting, Cyclone, Stack,

Air Heater

STEP-14

Sizing & Create Coal Silo, Inert, Limestone

Create drawing, specification of silo system

STEP-15

Create Specification & Sizing of Coal Crusher & System

Create emission equipment, baghouse, dust collector (if required)

STEP-16

Create Equipment List & Data Sheet:

Primary Air Fans, Secondary Air Fans, Blower,

Feed Pump, Start-up burner, Damper,

Ash Screw Cooler,

Soot blower, Chemical Injection System, etc.

STEP-17

Create Valve List & Valve Data Sheet:

Manual valve, pneumatic block valve, MOV,

Control Valve, Blowdown valve, desuperheater system, etc.

STEP-18

Create Instrument List & Instrument Data Sheet:

Flow/pressure/temperature transmitter/gauge

Flue gas analyzer & sampling system

Water/steam sampling and analyzer

Create Bill of material of instrument tube & fitting

Create drawing & bill of material cabling system

STEP-19

Boiler Operation and Control Concept

Create functional control diagram

Create logic diagram

Verify/Iterate with P&ID and Selected Equipment

STEP-20

Electrical System

Create bill of material of electrical

Create drawing & bill of material electrical cabling system

STEP-21

Pipe routing for external piping & 3-D Drawing, Pipe Stress Analysis

Feedwater piping system, steam piping system,

fuel/inert/limestone piping system, ducting for flue gas

Iteration with selected equipment

STEP-22

External piping: Pipe Stress Analysis & Pipe Support Drawing

Pipe Insulation System, Ducting & Casing Insulation System

STEP-23

Refractory Lining System

Anchoring System, Material Selection, Testing and Installation Procedures

STEP-24

Iteration to previous STEP, to verify selected equipment

with design data.

Note:

In general, as one system of boiler, each of process and step need to be verified and iteration with other process or system.

Drawing output, data sheet, etc. will be submitted to sub-vendor for fabrication, manufacturing or equipment supply.

Selected equipment shall be verified with the design data, iteration process is required to verify the design data compare to manufacturer data.