One of the uses of eddy current instruments is for the measurement of electrical conductivity. The value of the electrical conductivity of a metal depends on several factors, such as its chemical composition and the stress state of its crystalline structure. Therefore, electrical conductivity information can be used for sorting metals, checking for proper heat treatment, and inspecting for heat damage.

The technique usually involves nulling an absolute probe in air and placing the probe in contact with the sample surface. For nonmagnetic materials, the change in impedance of the coil can be correlated directly to the conductivity of the material. The technique can be used to easily sort magnetic materials from nonmagnetic materials but it is difficult to separate the conductivity effects from the magnetic permeability effects, so conductivity measurements are limited to nonmagnetic materials. It is important to control factors that can affect the results such as the inspection temperature and the part geometry.

Conductivity changes with temperature so measurements should be made at a constant temperature and adjustments made for temperature variations when necessary. The thickness of the specimen should generally be greater than three standard depths of penetration. This is so the eddy currents at the back surface of the sample are sufficiently weaker than the variations in the specimen thickness that are not seen in the measurements.

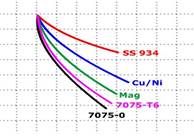

Generally large pancake type, surface probes are used to get a value for a relatively large sample area. The instrument is usually setup such that a ferromagnetic material produces a response that is nearly vertical. Then, all conductive but nonmagnetic materials will produce a trace that moves down and to the right as the probe is moved toward the surface. Think back to the discussion on the impedance plane and these type of responses make sense. Remember that inductive reactance changes are plotted along the y-axis and resistance changes are plotted in the x-axis. Since ferromagnetic materials will concentrate the magnetic field produced by a coil, the inductive reactance of the coil will increase. The effects on the signal from the magnetic permeability overshadow the effects from conductivity since they are so much stronger.

When the probe is brought near a conductive but nonmagnetic material, the coil’s inductive reactance goes down since the magnetic field from the eddy currents opposes the magnetic field of the coil. The resistance in the coil increases since it takes some of the coil’s energy to generate the eddy currents and this appears as additional resistance in the circuit. As the conductivity of the materials being tested increases, the resistance losses will be less and the inductive reactance changes will be greater. Therefore, the signals will be come more vertical as the conductivity increases, as shown in the image above.

To sort materials using an impedance plane device, the signal from the unknown sample must be compared to a signal from a variety of reference standards. However, there are devices available that can be calibrated to produce a value for electrical conductivity which can then be compared to published values of electrical conductivity in MS/m or percent IACS (International Annealed Copper Standard). Please be aware that the conductivity of a particular material can vary significantly with slight variations in the chemical composition and, thus, a conductivity range is generally provided for a material. The conductivity range for one material may overlap with the range of a second material of interest, so conductivity alone can not always be used to sort materials. The electrical conductivity values for a variety of materials can be found in the material properties reference tables.