Real control of industrial processes is almost always burden with various perturbations, disturbances and changes in process parameters or dynamics due to varying operational conditions, plant properties themselves, etc. Furthermore, an acceptable a priori mathematical model does not have to be known. In spite of it, such processes have to be controlled.

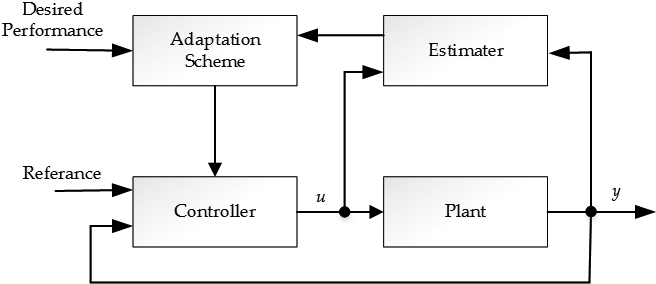

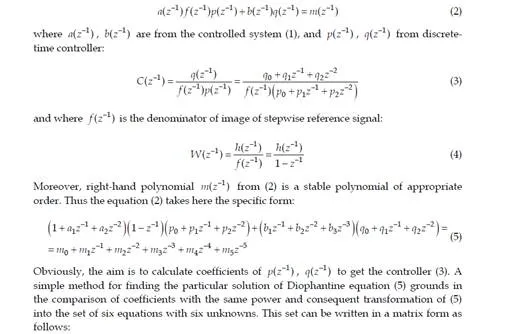

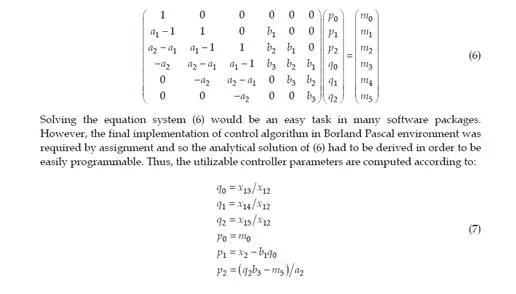

A possible solution to this task represents an area of control theory known as adaptive control or more specifically usage of self-tuning controllers (Åström & Wittenmark, 1973); (Åström et al., 1977); (Clarke & Gawthrop, 1979); (Åström & Wittenmark, 1989); (Wellstead& Zarrop, 1991); (Isermann et al. 1992); (Hang et al., 1993); (Bobál et al., 1999); (Bobál et al.,2005). Main idea consists in modification of control law according to the changing plant parameters obtained via recursive identification. Their advantage is some kind of “intelligent” behaviour, but on the other hand these regulators are quite complex and not easily applicable.This chapter deals mainly with software implementation of selected digital self-tuning control algorithms into the Matlab and Pascal environment for the purpose of possible industrial utilization. The work was motivated by co-operation with a manufacturer of aluminium-based rolled products and packaging materials. His project has supposed primarily the application of discrete-time adaptive compensator to control of a metal smelting furnace. Other requirements were the plant model with “a2b3” structure and final implementation in Borland Pascal (because of integration into the existing system).

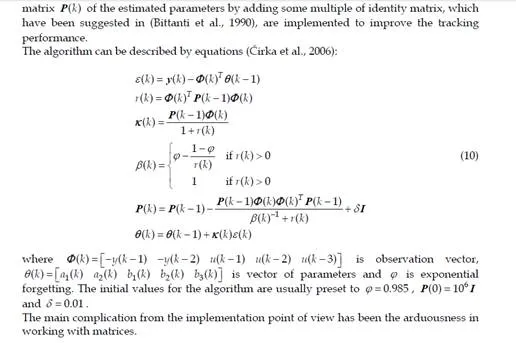

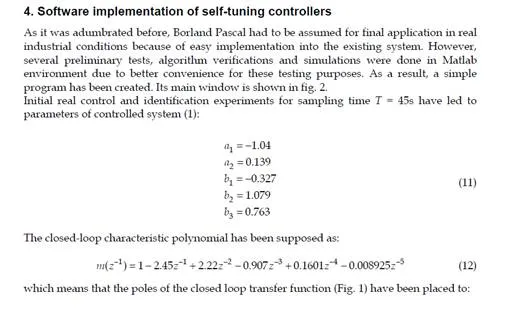

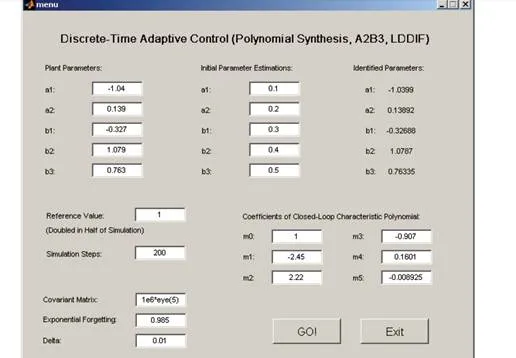

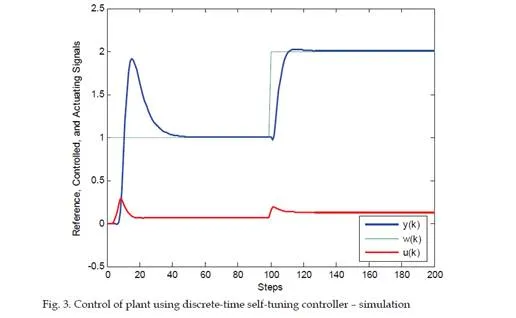

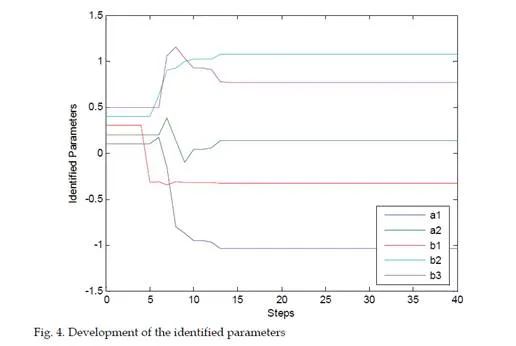

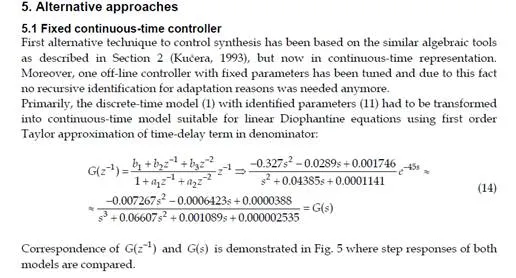

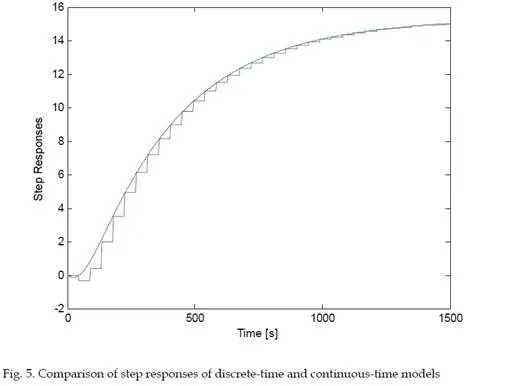

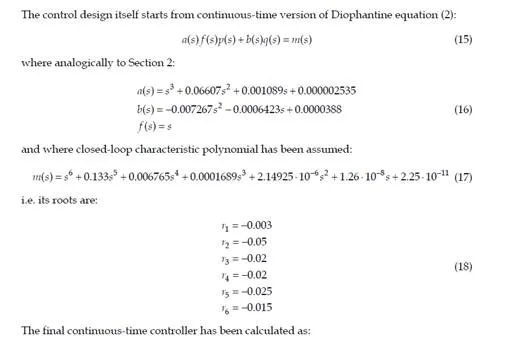

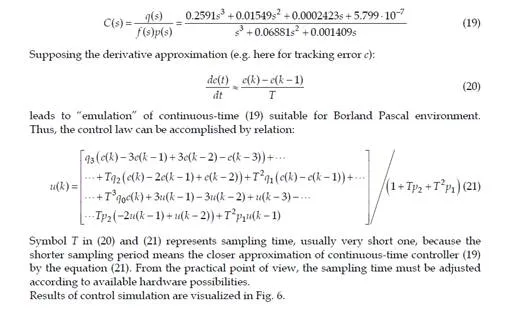

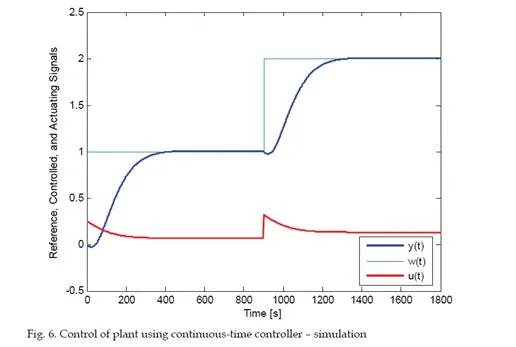

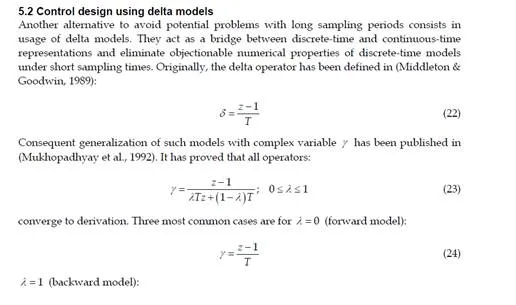

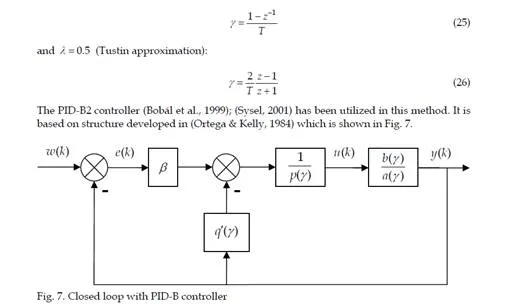

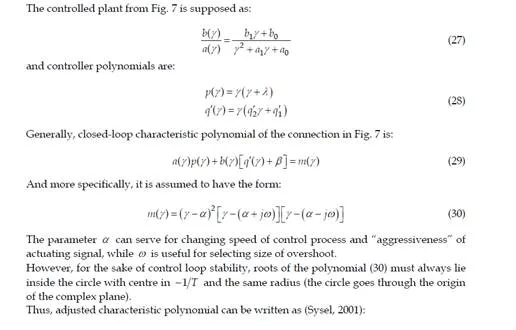

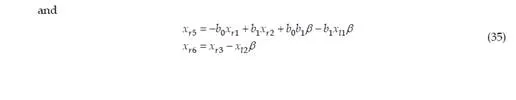

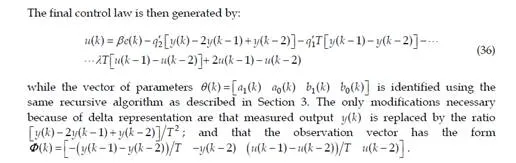

However the paper presents not only derived relations applicable to Pascal environment but also program for simulative purposes and testing created under Matlab and some preliminary simulation results. In the first stage, the applied methods have included a polynomial approach to discrete-time control design and recursive least-squares identification algorithm LDDIF, but subsequently also two alternative techniques, namely control using continuous-time regulator with fixed parameters and use of delta approach in self-tuning control, have been verified. Although all the tasks were motivated by our specific problem, the whole chapter tries to present them in more or less generally applicable way. The chapter is organized as follows. In Section 2, basic theoretical background of digital self- tuning controllers using polynomial synthesis and applicable relations are provided. The Section 3 then contains the fundamentals of related recursive identification algorithm LDDIF. Next, the Section 4 describes the preliminary software implementation and demonstrates its facilities on an application-oriented example. Furthermore, design and utilization of fixed continuous-time controller along with self-tuning control using delta models as two various alternative approaches are presented in an extensive Section 5. And finally, Section 6 offers some conclusion remarks.The preliminary version of this work has een presented at conferences (Matušů & Prokop,2009), (Matušů et al., 2009).

Discrete-time polynomial synthesis

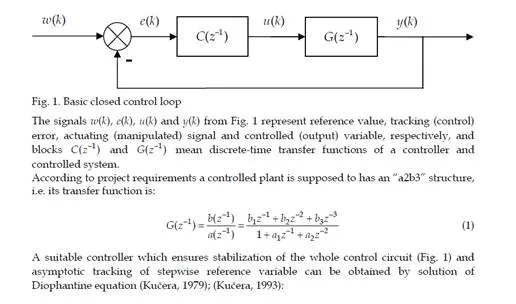

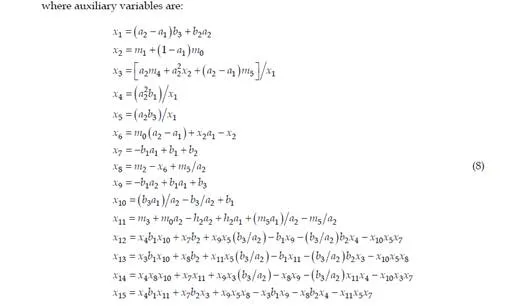

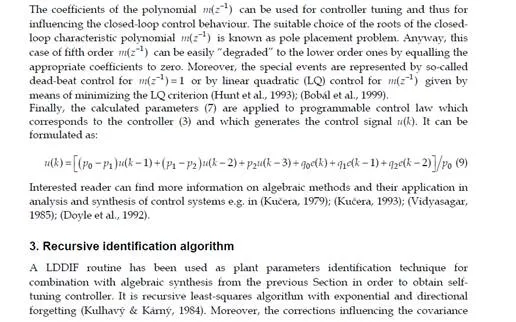

In the first instance the digital self tuning controllers were intended to be implemented. Their very basic principle consists in consecutive identification of the controlled process using a recursive algorithm (see the following Section) and application of obtained plant parameters in computing the control law. The control design itself has been based on algebraic approach and pole placement (Kučera, 1979); (Kučera, 1993); (Wellstead et al.,1979); (Åström & Wittenmark, 1980).Despite the existence of more complex control configurations, just the very basic single- input single-output (SISO) control loop with one degree of freedom has been assumed. This classical feedback connection in a discrete-time sense is shown in Fig. 1.

Conclusion

This chapter has been focused mainly on preliminary software implementation of digital self- tuning controllers into the Matlab (for simulative and testing purposes) and Pascal (for real application) environment. The motivation to this task as well as basic conditions and restrictions have been based on technical assignment of a manufacturer of aluminium-based products related to control of a metal smelting furnace. In the first instance, the applied techniques have comprised a polynomial approach to discrete-time control design and recursive least-squares identification algorithm LDDIF. On top of that, continuous-time controller with fixed parameters and delta approach in self-tuning control have been utilized. The future work should eventually lead to complete real-time industrial application.