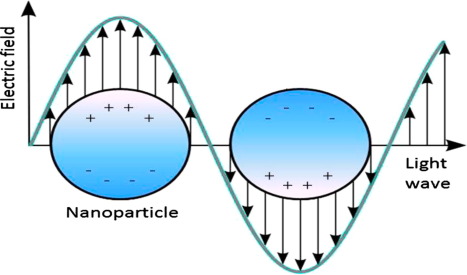

· Nanoscience is the science of objects with typical sizes of 1-100 nm. If matter is divided into such small objects the mechanical, electric, optical, and magnetic properties can change.

· Simply by finely dispersing ordinary bulk materials new properties can be created: inert materials become catalysts, insulators become conductors, or stable materials become combustible.

· Most properties of solids are altered when their dimensions approach the nanoscale. As an example, consider a particle of 1x1x1 nm3 . This contains roughly 43 = 64 atoms. Only 8 atoms of them are in the interior, while 87% of the atoms are at the surface. The electronic, magnetic, chemical, and mechanical properties of nanoparticles are therefore dominated by surface atoms.

Effect on Mechanical Properties:

· Elastic properties: thin films, enhances the elastic moduli by 2 to more factors when their film length is reduced to about 2 nm. Such elastic moduli are called as super modulus effect. This variations in modulus is fairly associated with variations in lattice spacings which can be measured by x-ray diffraction.

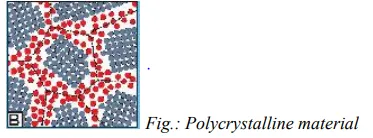

· Damping capacity: Enhancement in the apparent damping capacity of the polycrystalline films deposited on substrates above certain temperatures (300 ˚C). These enhancements may be associated with grain-boundary sliding within the nanostructured materials

· Plastic Properties: Enhancements in the yield strength, ultimate tensile strength and hardness. This hardness enhancement is due to interface strengthening effects.

· Wear and friction: Tribology studies conducted on nanocoating’s onto steel substrates indicated the enhanced wear resistance both to lubricated and unlubricated sliding.

· Mechanical strength : Nano-composites are materials in which inorganic particles, after suitable compatibilization, are used to improve the mechanical strength of organic polymers. Since nanoparticles are smaller than the wavelength of light they are invisible. One reason for the success of composite materials is that embedded particles can significantly improve the mechanical strength of the matrix. This can be achieved by mixing the nanoparticles into the organic polymer.

· Tough and hard: Nanocrystalline materials which are polycrystalline are defined as materials with grain sizes from a few nanometres up to 100 nm which show improved toughness and hardness. Because polycrystalline material has large pockets of regularity (crystal) in a “sea” of atoms that are not ordered (amorphous region).

· Self-organized nano-precipitates in ultrahigh strength steels: Steels with a ultrahigh strength above 1 GPa and good ductility above are of paramount relevance for light weight engineering design strategies and corresponding CO2 savings. Raabe et al. developed a new concept for precipitation hardened ductile high strength martensitic and austenitic-martensitic steels with even up to 1.5 GPa strength. The alloys are characterized by a low carbon content (0.01 wt.% C) and 9-15 wt.% Mn to obtain different levels of austenite stability, and minor additions of Ni, Ti, and Mo (1-2 wt.%). The latter elements are required for creating nano-precipitates during aging heat treatment.

· Self-healing plastic nanocomposites: Plastic components break because of mechanical or thermal fatigue: Small cracks, large cracks, catastrophic failures. Self-healing is a way of repairing these cracks without human intervention. Those plastics have nano-capsules that release a healing agent when a crack forms. The agent travels to the crack through nano-capillaries similar to blood flow to a wound. Polymerization is initiated when the agent comes into contact with a catalyst embedded in the plastic. The chemical reaction forms a polymer to repair the broken edges of the plastic. New bond is complete in an hour at room temperature.

· Strong and light weight: Carbon Nanotubes are 100 times stronger than steel but six times lighter.

· Usage of nanomaterials in vehicles, undergo reduction in its weight, which lead to decrease in gasoline consumption and reduces the cost of spacecraft launching. Totally economy of the country will increase.