Turbine is a device which is used to convert the kinetic energy of the moving fluid is converted in to the mechanical power by using the reaction or impulse

Types of turbines:

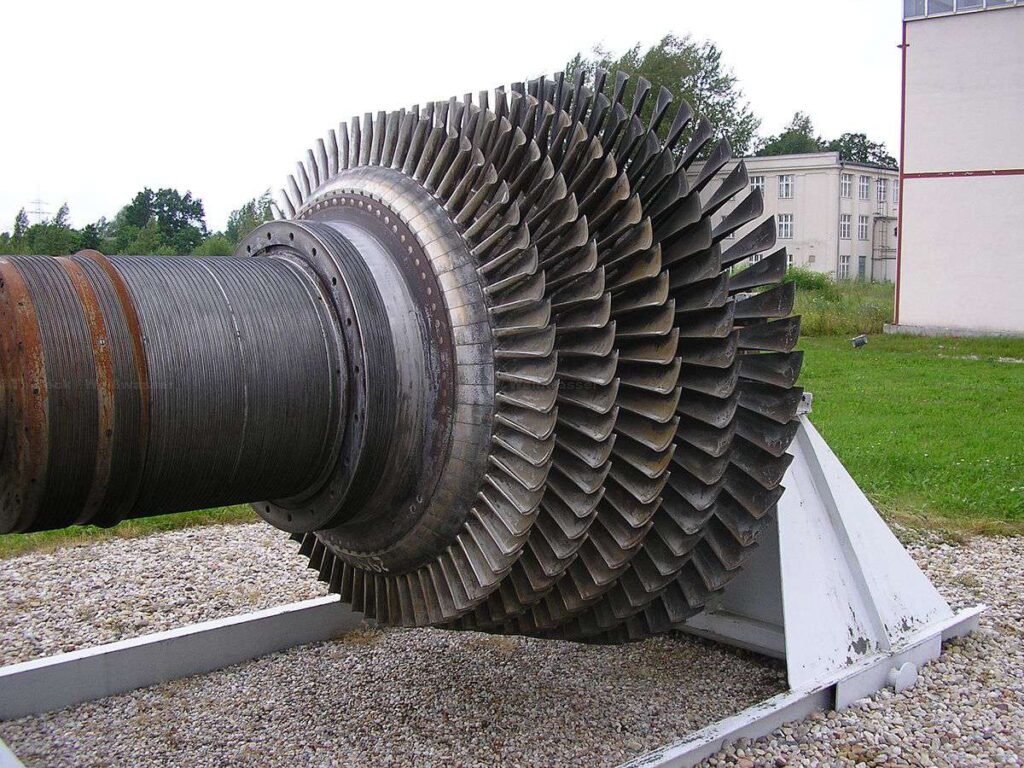

Steam Turbine:

Mainly the steam turbines are used in the thermal power plants for the generation of the electricity. For the generation electricity they use fuel oil, Coal or nuclear fuel. Ships propellers are used directly to drive the mechanical devices. But known reduction gear applications are used otherwise intermediate electrical step is used. The turbine is mainly used for the generation of the electricity. In this the electrical motor is connected to the mechanical load.

Gas Turbines:

Sometimes the gas turbines are referred to the turbine engine. The engine consists of compressor, fan, inlet, nozzle, combustor and also one or more turbines.

Transonic Turbine:

Throughout the expansion process the gas flow in the most of the turbines are employed in gas turbine engines remains supersonic. The gas flow must be supersonic in the transonic turbines. We can notice the gas flow from the nozzle guide vane exits. And the downstream velocities are normally become subsonic. These turbines are operated at the higher pressures. But it gives less efficient.

Contra rotating turbine:

It is also known as coaxial contra rotating. In this turbine the mechanism parts are rotates in the opposite direction with reference to the common axis to minimize the torque effect.

Statorless turbine:

It is a multistage turbine with a set of static inlet guide vanes. The guide vanes are direct to the gas flow on to the rotating rotor blade. The gas flow must be existing an upstream rotor impinges on the downward rotor without any intermediate set of stator vanes being encountered in the statorless turbine.

Ceramic turbine:

In the ceramic turbine the high pressure conventional turbine blades are made from the nickel based alloys. To prevent the metal from overheating internal air cooling flow is provided for the metals. In gas turbine ceramic blades are manufactures and there only tested by increasing the rotor inlet temperature and eliminate the air cooling. Compare to metals ceramic blades are more brittle. It carries a risk of catastrophic blade failure. So it limits the usage in the gas turbines and jet engines to the stator blades.

Shrouded turbine:

At the top they provide covering for many rotor turbines and those are interlock with the adjacent blades. Damping must be increases and reduce the blade excitement. In land based electricity generation steam turbine covering is often supplemented. We can see them mainly in the long blades of the low turbines with mixing wires. These wires are taken from the drilled holes in to the blade with suitable distance from the root of the blade. Normally wires are attached to the blades where pass through the point. Mixing wire reduces the blade covering in the central part of the blades. To reduce the instance of the blade failure mixing wires are introduced in low pressure turbines.

Shroudless turbine:

To eliminate the rotor covering and to reduce the centrifugal loads on the blade and cooling equipment is possible in the Shroudless turbine.

Bladeless turbine:

Bladeless turbine is also known tesla turbine. It uses the boundary layer effect and not a fluid impinging upon the blades as in a conventional turbine.