Assembly involves the joining together of two or more separate parts to form new entity which may be assembly or subassembly.

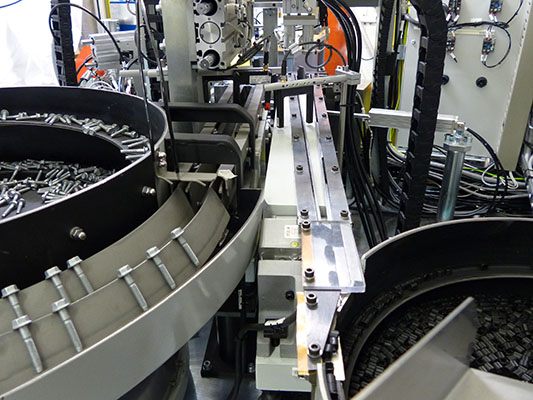

Automated assembly refers to the use of mechanized and automated devices to perform the various functions in an assembly line or cell.

Automated assembly system performs a sequence of automated operations to combine multiple components in to a single entity which can be a final product or sub assembly.

Automated assembly technology should be considered when the following condition exists.

· High product demand

· Stable product design

· The assembly consists of no more than a limited number of components.

· The product is designed for automated assembly.

Automated assembly system involves less investment compared to transfer lines because

1. Work part produced are smaller in size compared to transfer lines.

2. Assembly operations do not have the large mechanical forces and power requirement

3. Size is very less compared to transfer lines.

Designs For Automated Assembly

Recommendations and principles that can be applied in product design to facilitate automated assembly

Reduce the amount of assembly required:

This principle can be realized during design by combining functions within the same part that were previously accomplished by separate components in the product. The use of plastic molded parts to substitute for sheet metal parts is an example of this principle. A more complex geometry molded into a plastic part might replace several metal parts.

Although the plastic part may seem to be more costly, the savings-in assembly time probably justify the substitution in many cases.

Use modular design:

In automated assembly, increasing the number of separate assembly steps that are done by a single automated system will result in an increase in the downtime of the system. To reduce this effect, Riley suggests that the design of the product be modular, with perhaps each module requiring a maximum of 12 or 13 parts to be assembled on a single assembly system. Also, the subassembly should be designed around a base part to which other components are added.

Reduce the number of fasteners required:

Instead of using separate screws and nuts, and similar fasteners, design the fastening mechanism into the component design using snap fits and similar features. Also, design the product modules so that several components are fastened simultaneously rather than each component fastened separately.

Reduce the need for multiple components to lie handled at once:

The preferred practice in automated assembly machine design is to separate the operations at different stations rather than to handle and fasten multiple components simultaneously at the same workstation. (It should be noted that robotics technology is causing a rethinking of this practice since robots can be programmed to perform more complex assembly tasks than a single station in a mechanized assembly system.

Limit the required directions of access:

This principle simply means that the number of directions in which new components are added to the existing subassembly should be minimized. If all of the components can be added vertically from above, this is the ideal situation. Obviously, the design of the subassembly module determines this.

Require high quality in components:

High performance of the automated assembly system requires consistently good quality of the components that are added at each workstation. Poor-quality components cause jams in the feeding and assembly mechanisms which cause downtime in the automated system.

Implement hopper ability:

This is a term that is used to identify the ease with which a given component can be fed and oriented reliably for delivery from the parts hopper to the assembly work head.