Posted inMaterial Science

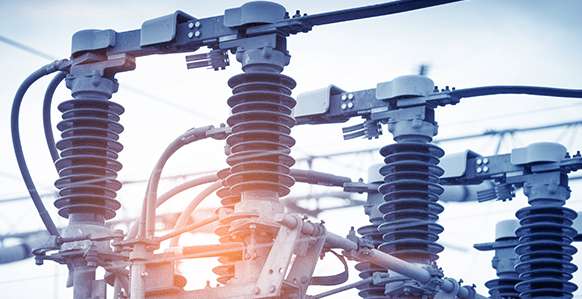

Dielectric strength

All insulating materials fail at some level of applied voltage, and ‘dielectric strength’ is the voltage a material can withstand before breakdown occurs. Dielectric strength is measured through the thickness of the material (taking care to avoid surface effects) and is normally expressed as a voltage gradient (volts per unit length). Note that the voltage gradient at breakdown is much higher for very thin test pieces (<100µm thick) than for thicker sections. The value of dielectric strength for a specimen is also influenced by its temperature and ambient humidity, by any voids or foreign materials in the specimen, and by the conditions of test, so that it is often difficult to compare data from…