Posted inUnconventional Manufacturing Process

WIRE CUT ELECTRICAL DISCHARGE MACHINING (WCEDM)

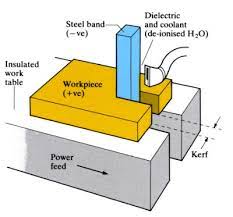

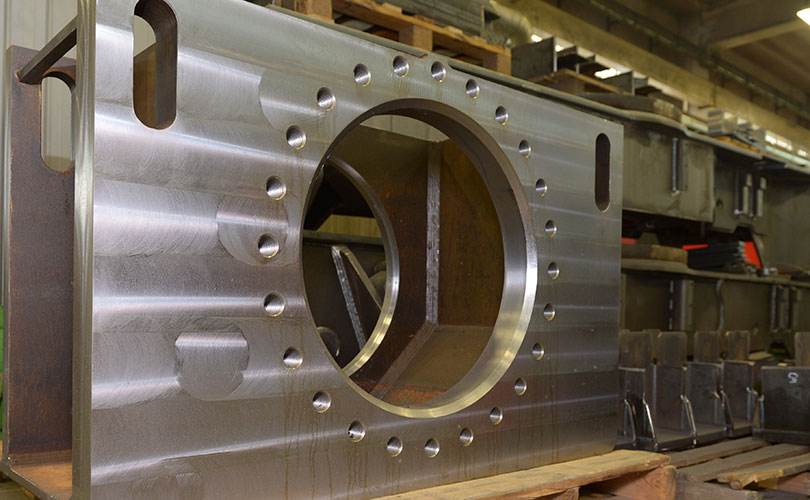

EDM, primarily, exists commercially in the form of die-sinking machines and wire- process, a slowly moving wire travels along a prescribed path and removes material from the workpiece. Wire EDM uses electro-thermal mechanisms to cut electrically conductive materials. Thematerial is removed by a series of discrete discharges between the wire electrode and the workpiece in the presence of dielectric fluid, which creates a path for each discharge as the fluid becomes ionized in the gap. The area where discharge takes place is heated to extremely high temperature, so that the surface is melted and removed. The removed particles are flushed away by the flowing dielectric fluids. The wire EDM process can cut intricate components for the electric and aerospace industries. This non-traditional machining process is widely used to pattern tool steel for die manufacturing cutting machines (Wire EDM). The concept of wire EDM is shown in this Figure. Figure: Wire erosion of an extrusion die The wires for wire EDM is made of brass, copper, tungsten, molybdenum. Zinc or brass coated wires are also used extensively in this process. The wire used in this process should posse’s high tensile strength and good electrical conductivity. Wire EDM can also employ to cut cylindrical…