Posted inUnconventional Manufacturing Process

ELECTRICAL BASED PROCESSES

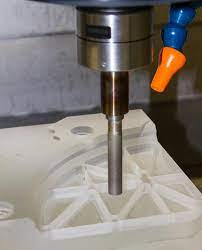

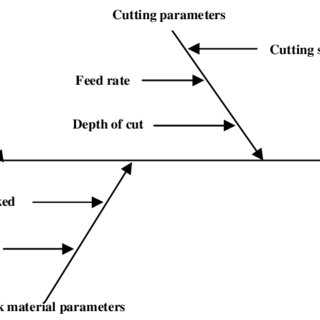

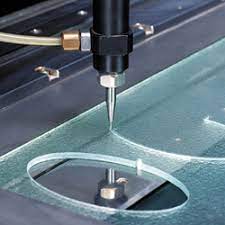

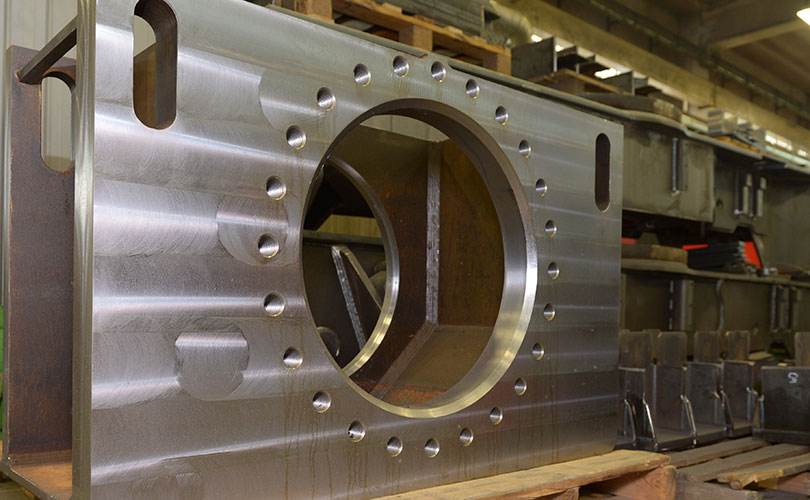

• Electrical Discharge `Machining (EDM) • Wire Cut Electrical Discharge Machining (WCEDM) Electrical Discharge `Machining (EDM) Electrical discharge machining (EDM) is one of the most widely used non-traditional machining processes. The main attraction of EDM over traditional machining processes such as metal cutting using different tools and grinding is that this technique utilizes thermoelectric process to erode undesired materials from the work piece by a series of discrete electrical sparks between the workpiece and the electrode. A picture of EDM machine in operation The traditional machining processes rely on harder tool or abrasive material to remove the softer material whereas non-traditional machining processes such as EDM uses electrical spark or thermal energy to erode unwanted material in order to create desired shape.So, the hardness of the material is no longer a dominating factor for EDM process. A schematic of an EDM process is shown in Figure 2, where the tool and the workpiece are immersed in a dielectric fluid. Figure: Schematic of EDM process EDM removes material by discharging an electrical current, normally stored in a capacitor bank, across a small gap between the tool (cathode) and the workpiece (anode) typically in order Application of EDM The EDM process has the ability to machine hard, difficult-to-machine materials. Parts with complex, precise and irregular shapes for forging, press tools, extrusion dies, difficult internal shapes for aerospace and medical applications can be made by EDM process. Some of the shapes madeby EDM process are shown in Figure.…