Development of information and communication technologies has influenced the evolution of all kinds of computer applications in the organization. At the same time external environment and phenomenon of globalisation have become more complex with new requires and conditions for enterprises. In that context, effective information system has become necessity for every organization in order to increase competitiveness by cutting down costs through better logistics. In these circumstances enterprises have two challenges: to create and implement an infrastructure for information technologies with applications for storing and sharing information and to effectively use these information for decision making process. Success for enterprises depends upon a significant flow of information and goods in the supply chain, client relationship and the ability to perform e-business (Vuković et al.,2007). E-business is concerned specifically with information systems solution packages used by enterprises for e-business transaction purposes for meeting customer requirements in Business-to-Business (B2B) and Business-to-Consumer (B2C) exchanges. Popular among the e-business applications for B2B are Supply Chain Management (SCM) and Enterprise Resource Planning (ERP) systems and may include online purchase or procurement between customer and supplier. For B2C e-business application the best example is Customer Relationship Management (CRM) system. Information technology includes all matters concerned with the computer science and technology, design, development, installation and implementation of information systems and applications.

IT is a framework for achieving strategic goals of an enterprise that incorporates a variety of commercial software packages that are related to various areas of an organisation such as finance, accounting, human resources, inventory, procurement and customer service. It is recognized that the ability to provide right information at the right time brings a great advantage to the world of complex business relationships and competitiveness.ERP as an enterprise-wide set of management tools that balance demand and supply, having the ability to link customers and suppliers into a complete supply chain, to employ proven business processes for decision-making, and to provide high degrees of cross- functional integration among sales, marketing, manufacturing, operations, logistics, purchasing, finance, new product development, and human resources, thereby enabling people to run their business with high levels of customer service and productivity, and to simultaneously lower costs and inventories, while providing the foundation for effective e- commerce (Wallace & Krezmar 2001).ERP as an e-business application for B2B allow the organisation to better understand its business, resources and plan for the future (the popular ERP packages in the market are: SAP, BAAN, Oracle Financials JD Edwards and People soft).The purpose of this paper is to explore ERP concept and its implementation in enterprises. The research framework examines importance of ERP concept and its implementation as a main factor for competitiveness for large Croatian enterprises. The result of the research reveals that the ERP systems are not insufficiently used in large Croatian enterprises. Details of the results, implications of the findings, and conclusions are presented and discussed. The present study provides a starting – point for further research of implementation process of ERP systems in Republic of Croatia.

ER Phistorical perspectives

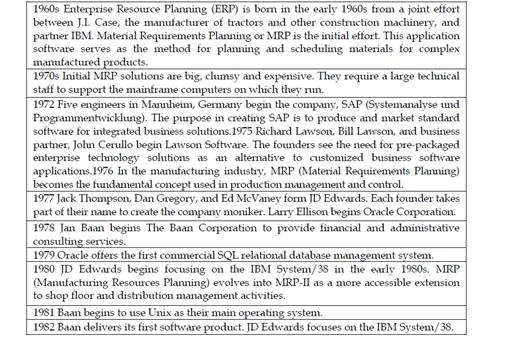

The evolution of ERP systems is a reflection of added layers of functionality to its germ-cell Materials Requirements Planning (MRP) of the 70’s. Manufacturing Resource Planning (MRP II) emerged in the 80’s and then followed by Enterprise Resource Planning (ERP) systems in the 90’s and ERP II in the 2000’s (see Table 1). ERP offers one integrated solution that aligns information technology and business processes into one repository. The ERP progression parallels the development of the economy, which was considerably instituted on the tangible assets during the 70’s. But, over time this dependency gradually skewed towards the intangible assets and intellectual capital.

Phase1:Manufacturing integration(MRP)

MRP systems were developed in the ‘70s. MRP is connected with simple production operations. It represents a more advanced concept of earlier efforts to process the bill of materials. The inventors of MRP were looking for a better method for ordering material, and they found it in that concept. The basic concept for planning material requirements is based upon the four questions which represent its logic (Vuković et al., 2007):

• What are we going to make?

• What does it take to make it?

• What do we have?

• What do we have to get?

These four questions are called the universal manufacturing equation. It has a logic that is applied in production enterprises. MRP simulates the universal manufacturing equation. It uses the master schedule to answer the question what are we going to make, the bill of material to answer the question what does it take to make it, and inventory records to answer the question what do we have, and to determine future requirements, thus answers the question what do we have to get. The main function of MRP is to guarantee the availability of a required material. MRP is used for planning the supply and production of materials for internal use, assembly, production or distribution, and it has to be available at the right time and in the right quantity. The planning process includes monitoring of stock size, automatic creation of orders for materials, intermediate production or its divisions. By functioning in that way, MRP attempts to maintain a balance between the minimum safe inventory size and the costs. Classic inventory management treats every single material, element or product separately, not taking account of the frequency of use and consumption of one part or another. The MRP approach is different because a lot of customers order individual products in packages, so that demand is not entirely independent. There must be a connection between demand of nuts and bolts, paint and brushes, etc. MRP recognizes this connection and attempts to balance demand and supply (Vuković et al., 2007).

MRP becomes a formal mechanism for priority management in changing production surroundings. The changes in production surroundings are not possible or probable—they are inevitable. The function of MRP that is directed at keeping deadlines and on changes in the production of enterprises is called the Priority Planning. Capacity is a factor that is of equal importance when compared with the previous two factors (Wight, 1993).

Tools for capacity planning in the production enterprise, as related to the MRP computer system are:

• Sales and operations planning,

• Master scheduling,

• Demand management,

• Rough-cut capacity planning.

The total development of these tools has led to the next step of planning evolution. Due to the above MRP shortcomings in the 1970’s, the Manufacturing Resource Planning system (MPR II) has emerged in the 1980’s. Sadagopan (1998) stated that, unlike MRP, MRP II addresses the entire manufacturing function and not just a single task. The increased functionality enabled MRP II to check the feasibility of a production schedule taking into account the constraints, and to adjust the loading of the resources, if possible, to meet the production schedule. While Siriginidi (2000) added the possibility of the integration with other shops , MRP II has certain extensions like rough cut capacity planning and capacity requirements planning for production scheduling on shop floor as well as feedback from manufacturing shops on progress of fabrication. This last functionality requires a more integrated system. MRP II is more than a material management tool as indicated by Koch (2001) and within the logistic vision, the technology of MRP II, manufacturing resource planning offers an interpretation of both the main problems of manufacturing as material flow, and the tools and procedures needed to solve these problems by realizing a full control system. However, Swan et al (2000) observed that MRP II has been widely promoted by technology suppliers as the definitive “best practice” solution for production management and control. But, enterprises have encountered many problems in implementing MRP II – including organizational not just software. However, prior to these findings, Foxlow (1994) reported that there is a need for new knowledge-based manufacturing software, incorporating

artificial intelligence techniques, offers benefits to companies whose products are complex, highly varied, or made-to-order. However, these are precisely the areas where conventional MRP II systems are widely perceived as having failed.

Phase2:Enterprise resource planning(ERP)

With the evolution of concepts like MRP and MRP II, we arrive at the currently used concept of enterprise resource planning or ERP. The foundation for ERP is the same as in MRP II. ERP has developed as a set of business processes, thanks to the development of information and communication technologies, while its conceptual development is just one step in the evolution of enterprise management (Vuković et al., 2007).The ERP systems were also faced with their own implementation and integration problems. The major difficulties with integration, however, appeared during the augmentation of core ERP systems with legacy systems.

The main reasons to implement the ERP concept are (Vuković et al., 2007):

• Integration of financial information.

• Integration of clients orders.

• Standardization and speed of production processes.

• Stock sizing.

• Human resources information standardization.It is essential is to draw a difference between

the concept of ERP and the ERP system. ERP systems enable the realization of the ERP concept.

Phase3:Customer-centric ResourcePlanning(CRP)

The range of ERP functions was further expanded at the end of the 1990s to include “front office” functions such as sales, marketing and e-commerce. E-commerce applications needed to be connected to back-end systems and thus forced many ERP software providers including SAP, PeopleSoft and BAAN_ to reinvent themselves as CRP providers. While traditional ERP solutions were equipped to support the “make-to- stock configure-to-order business model”, CRP systems are able to meet the e-commerce “build-to-order fulfil-to- order” requirement. Effective manufacturing and service delivery in the e-commerce model require customer-centric, continuous planning instead of the classic ERP assumption of long planning cycles (Bosilj-Vukšić & Spremić, 2005).

Phase4:Inter-enterprise Integration(XRP)orERPII

Since the world of the 2000s has become one of interconnected enterprises creating global information systems, the scope of ERP systems comprises the entire value chain of the enterprise, its customers, suppliers and trading partners. The main goal of the XRP system is to provide intelligent decision-support capabilities in order to reduce inventory, foster strategic pricing, improve cycle times and increase customer satisfaction throughout the supply chain management and selling chain management. To achieve this goal, an XRP model must support the integration of external and internal business activities with the suppliers and customer’s information and processes (Bosilj Vukšić & Spremić, 2005). ERP systems were also faced with their own implementation and integration problems. The major difficulties with integration, however, appeared during the augmentation of core ERP systems with legacy systems.

Themistocleous and Irani (2001) stated that ERP systems were then introduced to overcome integration problems. However, organizations did not abandon their existing systems when adopting an ERP solution, as ERP systems focus on general processes and initially did not allow much customization. The problems of integration within the core of ERP systems have resulted in multiple shortcomings as reported by DeSisto (1997) that poor ERP integration resulted in high order error rates, incorrect billing and shipping addresses, misquoted pricing and discounts, and misquoted “out of stock” inventory.

ERP defined

There are a numerous definitions of ERP but in this paper the most popular definitions will be presented. Wallace and Krezmar define ERP as an enterprise-wide set of management tools that balance demand and supply, having the ability to link customers and suppliers into a complete supply chain, to employ proven business processes for decision-making, and to provide high degrees of cross-functional integration among sales, marketing, manufacturing, operations, logistics, purchasing, finance, new product development, and human resources, thereby enabling people to run their business with high levels of customer service and productivity, and to simultaneously lower costs and inventories, while providing the foundation for effective e-commerce. An enterprise resource planning system is a business management system that comprises integrated sets of comprehensive software that can be used, when successfully implemented, to manage and integrate all business processes and functions within an organization. They usually include a set of mature business applications and tools for financial and cost accounting, sales and distribution, management of materials, human resources, production planning and computer integrated manufacturing, supply chain, and customer information (Žabjek et al., 2008). Klaus, Rosemann and Gable define ERP as a logical and compact software solution which strives toward the integration of all processes in an organization, in the aim of presenting a comprehensive view of the organization through singularity of information and IT architecture (Roseman & Gable 2000), whereas Yen, Chou and Chang (Yen et al., 2002), describe ERP as a software which can be used to integrate information through all functions of organization in order to automate all business processes. Rao (2000) described an ERP system as a software solution to produce the right product on the right place, at the right time, and for the right price, containing the best industrial and management practice captured in those solutions. It is necessary to emphasize that ERP is not a software, software package or set of computer applications. Software packages of ERP systems, or ES, provide support for efficient resource planning or ERP.

The main function of ERP is to integrate operational procedures within the department, along with the MIS, and to relocate organizational resources in changing surroundings. ERP systems are integrated software solutions which are used for resource management of the organization. ERP systems are used for resource planning, and also for the concept of combining unique departments systems and utilizing the methods which are most appropriate for problem solving. The main goal of ERP is to implement the best practices for all business processes. It may be said that ERP is a key business strategy today, and the greatest advantage of its implementation is the ability to fundamentally eliminate multiple systems within an organization, with no more redundancy. Implementing ERP on platforms is not always easy because of the massive re-engineering process that involves security, quality assurance, and training for members of the organization entrusted to use the ERP systems. In addition to maximizing the operational effectiveness of the ERP, IT managers, system security officers, and system developers will find themselves challenged on security and control issues (Vuković et al. 2007).

Characteristics of ERP systems

When most people refer to the “core” ERP applications or “modules,” they mean the back- office capabilities to manage human resources, accounting and finance, manufacturing, and project-management functions. However, major ERP suites from Oracle, PeopleSoft, and SAP now provide much more—including modules for sales force automation, business intelligence, customer relationship management, and supply chain management (Musaji,2002).

There are some significant differences between ERP and non-ERP systems. These differences are (Musaji, 2002):

• In ERP systems, certain control procedures leave no documentary evidence of performance. For some other procedures, the evidence of performance is indirect; it may be included in the program logic or in the operator’s instructions. Therefore, compliance tests may have to be structured differently in an ERP environment and observation of the client’s procedures may become more important.

• In ERP systems, information is often recorded in a form that cannot be read without the use of a computer.

• Financial and business information is often generated automatically by ERP systems based on data previously entered, without further human instructions.

• Errors that might be observed in non-ERP systems may go undetected because of the reduced human involvement in computerized processing. There is a danger that errors in processing may be applied to a large number of transactions without being noticed.

• With proper controls, ERP systems can be more reliable than non-ERP systems. This is because ERP systems subject all data to the same procedures and controls. Non-ERP systems are subject to random human error. Although computer processing will usually be consistent, errors may still occur; for example, if the computer is incorrectly programmed.

• It is difficult to make changes after an ERP system has been implemented. Therefore, we should be aware of the organization’s plans to introduce significant new systems or to make major modifications to existing systems. It is advisable to review new systems or modifications before implementation so that a preliminary assessment can be made of the adequacy of control procedures, in order to ensure an adequate audit trail, and to plan any necessary changes in the audit approach. ERP systems vary from the simplest, batch-controlled type to complex integrated applications that perform a number of functions simultaneously.

Implementation of ERP systems

Parry and Graves (2008) noted that implementation of an ERP system does not end with the system “going live“ (Markus et al. 2000). It is an ongoing process where new functionality, modules, updates, and corrections need to be carried out in conjunction with changes in organisational processes (Kremmergaard & Moller 2000). These software and process changes continue throughout the lifetime of an ERP system as it evolves in parallel with the organisation. Many publications have described the ERP lifecycle as having different phases (Markus et al. 2000, Markus & Tanis 2000, Ross & Vitale 2000, Parry & James-Moore 2005); however, Markus and Tanis’s (2000) ERP lifecycle model has been widely accepted. They refer to an “enterprise systems experience cycle“, and describe four distinct phases within this journey: the “Chartering” phase during which decisions leading to the funding of an enterprise systems will be made; the “Project „phase where the ERP software is configured and rolled out to the organisation; the „Shakedown“ phase where the company makes a transition from go-live to normal operations; the “Onward and Upward „phase during which the company captures the majority of business benefits from the ERP system and plans further steps of technology implementation and business improvement. This final phase refers to the management of ERP systems that covers ERP operations, ERP upgrades, and ERP maintenance such as error fixing and minor enhancements (Markus et al. 2000, Markus & Tanis 2000, Nah & Lau 2001). Following initial implementation, there are subsequent revisions, re-implementations, and upgrades that transcend what is normally considered as management of ERP system (Chang 2004). Management activities for software systems are commonly classified as one of the four distinct types:

(1) corrective,

(2) perfective,

(3) adaptive, and

(4) preventive (Pressman 1992).

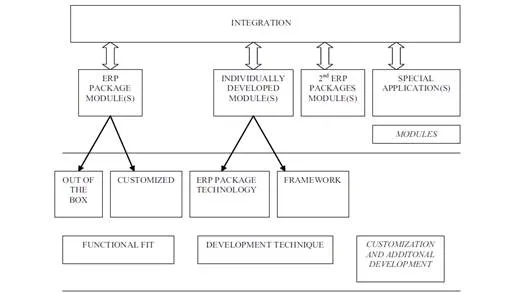

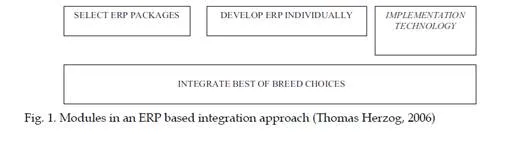

The figure 1 below shows how ERP can support IT process. It shows Modules in an ERP based integration approach.

Knowledge management era

Knowledge has become the most important input implemented in business organisations. Numerous books, articles and special editions of journals have already been devoted to explaining concept of knowledge and its management in organisations. It is not necessary to dwell on these, except to iterate that the key components of successful knowledge management are strategy, culture, technology, organisation and people (Drew, S., 2000). Different authors are bound to put different definitions of the knowledge management. For example, Wiig sees knowledge management as a process of facilitating and managing knowledge-related activities such as creation, capture, transformation and use (Wiig, 1997). Brooking understands knowledge management as an activity, which is concerned with strategy and tactics to manage human-centred assets (Brooking, 1997). On the other hand Bair defines it as a set of policies, organisational structures, procedures, applications and technologies intended to improve the decision-making effectiveness of a group or a firm (Bair, 1997). Finally according to Harris, knowledge management is a discipline that promotes a collaborative and integrated approach to the creation, capture, organisation, access and use of an enterprise’s information assets (Harris, 1998).Knowledge management comprises information, communication, human resources, intellectual capital, brands, etc. Knowledge Management (KM) has tactical and operational perspectives.

KM is more detailed and focuses on facilitating and managing knowledge- related activities such as creation, captures, transformation and use (e.g. Wiig et.al,). Enterprises tend to pursue one or several of five basic knowledge-centred strategies (Wiig, K. M., 1997):

• Knowledge strategy as business strategy – emphasises knowledge creation, capture, organisation, renewal, sharing, and use in all operations;

• Intellectual asset management strategy – emphasises enterprise-level management of specific intellectual assets such as patents, technologies, operational and management practices, customer relations, organisational arrangements, and other structural knowledge assets;

• Personal knowledge strategy – emphasises personal responsibility for knowledge- related investments, innovations and competitiveness, renewal, effective use and availability to other or knowledge assets within each employee’s area of accountability;

• Knowledge creation strategy – emphasises organisational learning, basic and applied research and development, and motivation of employees to innovate and capture lessons learned to obtain new and better knowledge that will provide improved competitiveness;

• Knowledge transfer strategy – emphasises systematic approaches to transfer knowledge to points of action where it will be use to perform work. This strategy includes knowledge sharing and adopting best practices.

Since the importance of knowledge rapidly grows, there is a growing need for knowledge management, especially the management of processes in which knowledge is created and used (Quintas & Geoff, 1997). Most authors observe human capital as a system consisted of three elements. The first element is intellectual capital. It refers to fundamental individual attributes such as cognitive complexity and the capacity to learn, together with the tacit and explicit knowledge, skills and expertise an individual builds over time (Gratton & Ghoshal,

2003). The second element of human capital is social capital – which is about who one knows, and how well one knows them. The third element is emotional capital based on a self-esteem, courage and resilience. These three different elements are highly inter-related. Social capital helps individuals to develop intellectual capital by accessing the knowledge and skills that those people possess. Emotional capital brings the integrity and self- awareness to build open and trusting relationships, which underpin the creation of social capital. As an example of the world leading company at the field of intellectual capital, it is mentioned Swedish insurance company, “Skandia”, which has comprehended the importance of knowledge and intellectual capital, ten years ago. For better insight of their business accomplishments, usually observation and furtherance, “Skandia” has developed the scheme for intellectual capital (intellectual capital is composed of several important following components): IC was seen as the sum of human and structural capital. Human capital was defined as the knowledge, skill and experience of employees. Structural capital, however, was the extension and manifestation of human capital into innovations, business processes and relationships with dealers and others (Roos, 1998). Intellectual capital management (ICM) and knowledge management (KM) are multidimensional and cover most aspects of an enterprise operation. There is overlap but there are also major differences. For example, KM has tactical and operational aspects and is more detailed. The ICM and KM role is to keep and sustain the present and future body of knowledge in order to guarantee the firm’s long-term viability and profitability. Management of knowledge is becoming a new business philosophy and is treated as a source of power and together with Intellectual Capital represent the enterprise’s future potential. There is considerable overlap in the scope of intellectual capital management and knowledge management. ICM focuses on building and governing intellectual assets from strategic and enterprise governance perspectives with some focus on tactics. Its function is to take overall care of the enterprise’s intellectual capital.

The management of intellectual capital is a strategic activity which positively modification efficiency of enterprises and means that the enterprise (Tipurić, D., 1999):

• Apprehended the role and importance of employees in resumption of competitive advantages;

• Defined its key competence in economic surroundings;

• Developed the system for creating necessity know-how;

• Installed the system of rewarding;

• Developed the specific culture for encouragement of experimenting and expanding total knowledge.

ERP concept and enterprise knowledge

ERP packages led to better production planning, quality and inventory control, expense management and more efficient distribution. The primary objective of ERP systems is to seamlessly improve the internal efficiency through order fulfilment. However, information on just one side of the business equation is ineffective in achieving a competitive advantage in the new global economy. The new market demands a distributed knowledge network, which necessitates the participation of the entire value chain from customer to supplier, and in some cases, even from competitors. Enterprises that strategically maximize the impact of these new knowledge flows will be in a position of competitive advantage in the emerging networked economy. This requires synergetic relationships between CRM, KM, and supply chain within one system (Mirghani, 2005). According to Thompson and Close (2001) since the beginning of 1997, the major ERP vendors (e.g., SAP, PeopleSoft and Oracle) have attempted to expand their dominant position in the financial, manufacturing and human capital management enterprise applications markets into the increasingly lucrative customer relationship management (CRM) market. Until recently, these attempts have mostly failed to meet client expectations. However, their labours are beginning to pay off.

Although ERP systems interconnect different departments through the various modules, but to some extent, ERPs initially created functional silos by enforcing the business process workflow through single technology.

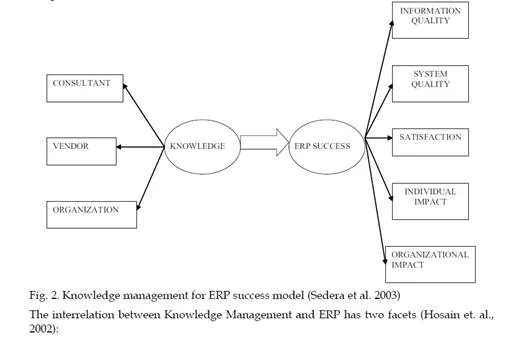

This silo effect needs to be counterbalanced by implementing KM initiatives that promote the communication and knowledge sharing among various value network collaborators. The KM initiative as supportive mechanism for ERP will reveal different kinds of knowledge to different stakeholders. The conventional ERP systems have tremendously improved order fulfilment and intra-organization business process workflow, but fell short to address the inter-enterprise business process complexities. The latter requires a full collaboration ecosystem that attracts valued customers and shareholders from all directions to share the pertinent business knowledge. The leverage of human intellectual capabilities has been the focus of ERP. Directing and maintaining intellectual energy while attempting a restructuring or re-engineering program is seen as a typically difficult example of this much overlooked area. Gartner defined ERP as “a business strategy and a set of industry-domain-specific applications that build customer and shareholder value by enabling and optimizing enterprise and inter-enterprise collaborative operational and financial processes”. This definition transformed the traditional back-office ERP system from internal transactional system into a complete value network system that incorporates the front-office functionalities for various partner communities. Integrating the front office with ERP indisputably offers an information visibility strategy that pushes the right information to the right people at the right time through the right communications channels (Mirghani, 2005). From systems point of view, ERP and KM systems need to be implemented simultaneously in the framework of integrated enterprise information systems. Simultaneous implementation of ERP and KM systems requires incorporation of both KM and ERP into enterprise business processes and incorporation of KM into ERP system development. Despite the different focus of ERP and KM systems, the two systems, to some extent, have common goals. Both ERP and KM aim at improving business processes to achieve better business performance, with tasks based on data, information and knowledge.

ERP systems emphasize the efficiency of business processes in enterprises. To achieve the goals, ERP systems maintain mechanism for data/information consistency through high degrees of standardization, formalization and specialization. KM systems devote to the knowledge processes of enterprises such as knowledge creating, storing, transferring and sharing. In perspectives of enterprises, the ultimate goals of the two systems are helping enterprise survive in the global market by improving their performance. In summary, ERP and KM systems manage the business from the point of views of physical and knowledge assets, respectively.

With a proper framework in which ERP and KM can cooperate with each other, an enterprise can benefit from the advantages of ERP and KM and be successful in global competition.

On the one side, implemented Enterprise Systems can serve as a main source for Knowledge Management. As Enterprise Systems support various areas of a company such as procurement, manufacturing, warehousing, sales, distribution, and accounting, an analysis of a run-time data can provide the knowledge manager cost-effectively with useful data about the current process performance. This perspective characterizes Enterprise Systems as a knowledge repository and can be described as “Enterprise Systems for Knowledge Management”.

• On the other side, the management and especially the implementation of an ES solution requires a substantial amount of specific knowledge and expertise. Thus, a separate ES- related Knowledge Management can be identified that covers the entire management of knowledge in an ES project. This perspective can be characterized as “Knowledge Management for Enterprise Systems”

In 2003 Sedera with his colleagues has proposed a model of Knowledge Management that is crucial for ERP success.In this study knowledge was identified as a key driver of ERP success but also needs further analysis to understand the complete influence of knowledge and other possible dimensions of knowledge.

ERP systems and it simple mentation inlarge Croatian enterprises

ERP systems can be considered as a “standard tool” for every large enterprise in a global economy and in the time of large competitiveness at the international market. For example “Supply Chain Management” includes e-procurement, payment and organizational optimization and without ERP as a integral source of data, ERP system will be impossible to implement.

The analysis “Enterprise Resource Planning Systems and competitiveness of large Croatian enterprises” conducted by Nikša Alfirević from the Faculty of Economics Split, Croatia in 2003 that has been accessible from the secondary source of research and has shown that the users of SAP information system in large Croatian enterprises can be divided in two main categories:

• Enterprises with a foreign proprietary – they buy ERP systems to follow standards of

“mother-companies”

• Small group of progressive domestic companies that are oriented to export and international business.

This research (Alfirević, 2003) has been conducted at the end of 2002 and the beginning of 2003. The summary of the most important conclusions of that research will be presented in this paper.The source for analysis has been 200 leading domestic enterprises (ranked by the income) and published in a study “Privredni vjesnik” in 2002. Although the analysis of 200 enterprises cannot show all trends at the ERP market, the fact is that this source presents the majority of potential ERP users and that from this analysis all relevant indicators of market situation can be measured. The analysis has shown that 68% of the surveyed enterprises do not have implemented ERP system and that ERP systems are not used enough. There is a large gap when is about investment in ERP systems in Croatia and in the rest of the world. This study has also shown that there is a significant correlation among ERP systems and relative performance measures ROA and Net profit margin (Spearman coefficient of correlation).Conducted analysis has also shown that in Republic Croatia there is a relatively low level of investment in ERP technologies but that enterprises that implement ERP achieve better

business results (it can be concluded that implementation of ERP systems is very important for competitiveness). It is possible to connote that the situation of ERP systems implementation in large Croatian enterprises has not change much in the years that have accompanied from the conducted research because all trends that are presented at the professional journals in Republic Croatia show this trend.Further researches and practice has to be oriented to adaptation of ERP systems to specifics of Croatian economy which will help to improve export capabilities and competitiveness of Croatian economy.

Conclusion

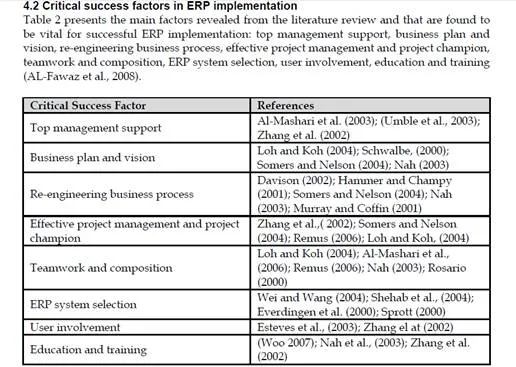

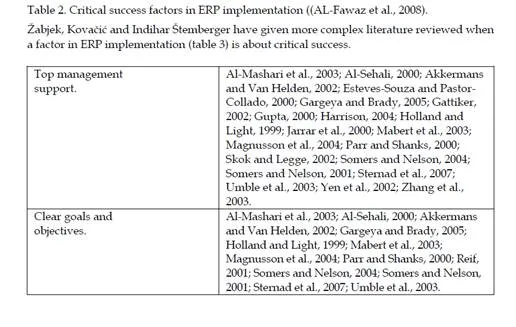

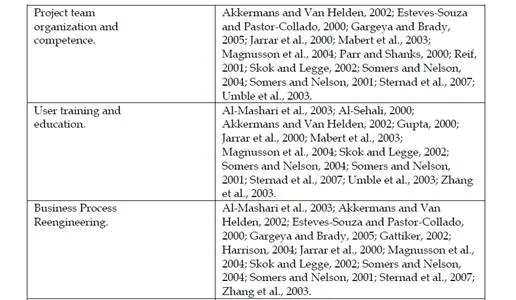

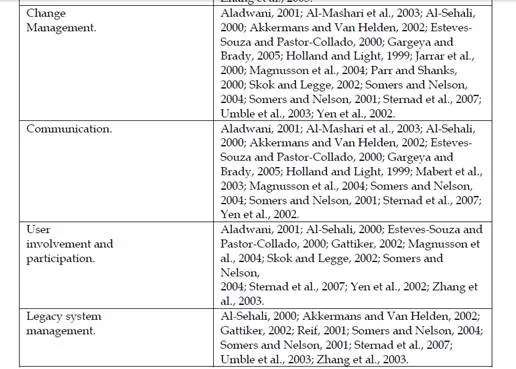

To adapt to today’s challenging and competitive business environment, organizations are implementing ERP systems to achieve a capability to plan and integrate enterprise and to be more responsive to customer demands.Today, ERP is still evolving, adapting to developments in technology and the demands of the market. Four important trends are shaping ERP’s continuing evolution: improvements in integration and flexibility; extensions to e-business applications, a broader reach to new users; and the adoption of Internet technologies. Taking a closer look at each will help you understand where ERP is headed. Despite the fact that ERP integrates and optimises the flow of information across the entire organization’s supply chain, the implementation of such software packages can be costly, and may even require reengineering the entire business operations. Combinations of factors have to be considered when undertaking an ERP implementation including: top management support, business plan and vision, Re-engineering business process, effective project management and project champion, careful package selection process, teamwork and composition, user involvement and education and training (Al-Fawaz et al., 2008). ERP and KM systems emphasize different characteristics, but the primary goal of the both systems is to improve the competitiveness of enterprises in global markets. From systems point of view, ERP and KM systems need to be implemented simultaneously in the framework of integrated enterprise information systems. Simultaneous implementation of ERP and KM systems requires incorporation of both KM and ERP into enterprise business processes and incorporation of KM into ERP system development. Despite the different focus of ERP and KM systems, the two systems, to some extent, have common goals. Both ERP and KM aim at improving business processes to achieve better business performance, with tasks based on data, information and knowledge. In this paper study of implementation of ERP systems in Republic Croatia has been shown. Analysis has shown that in Republic Croatia there is a relatively low level of investment in ERP technologies but that enterprises that implement ERP achieve better business results. It can be said that in the future enterprises in Republic Croatia and especially large Croatian enterprises have to orient more to advantages of IT especially when is about role of IT in improvement of export capabilities of large enterprises and in general when is about competitiveness of Croatian economy.