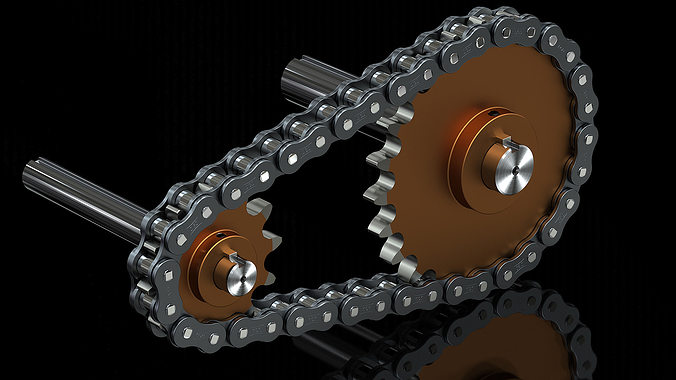

Chains and sprockets are indispensable elements in power transmission. The have an edge over all other methods of power transmission particularly when the drive and the driven point are situated at short centre distance from each other. They are also called as roller chain and sprockets because of the rollers that are used in the link.

Before we proceed to look at the constructional and classification aspects of the chain drive, we shall look at the salient points of the chain drive

1. The chain drive eliminates slip and creep and hence provides a constant speed ratio.

2. The chain and the sprocket both in majority cases being manufactured out of steel tend to wear out at a slower rate and hence a long life is always obtained.

3. They have the flexibility of a belt drive and can hence be used to drive a number of shafts from a single source.

4. They have the capability to work in very dirty environments with minimum care.

Here is a good example of the chain drive we use in our day to day life. The chain and sprocket drive in a bicycle. It is the best example for transmission of power from one point to another with a constant speed ratio.

Constructional aspects of Chain:

The chain is the main member in a chain drive made up by means of links interlocked by pins and rollers of specific diameter. The pins are arranged in a series at accurately timed intervals or pitch in order to match the pitch distance in the sprocket.

The material used for the manufacture of chains is alloy steel and they are normally punched out of steel plates.

The chains and sprockets are selected based on the torque to be transmitted. There are certain classification of the chains and sprockets based on the number of chains being used to transmit the torque. They are

5. When a single chain is used it is called a single strand.

6. When two chains are used (side by side) as shown in figure below it is called as duplex or double strand

7. When three chains are used, it is called as triplex strand.

The chains are basically specified on standardized numbers in various standards like ISO, DIN , ANSI, etc.

Construction aspects of Sprocket:

The sprocket is normally made of alloy steel and is tempered and case hardened at the tooth area in order to enhance the wear resistance of the material. By construction the sprockets either posses a hub with key for driving or holes (in automobiles) in order to be mounted.

A typical sprocket with hub and key is shown below.