New OPOC engine developments are causing a resurgence in interest in the engines. They offer the possibility of significant efficiency gains, possibly making them the green engine of the future.

Introduction

The opposed piston opposed combustion- OPOC for short – engine may just shake up the automotive world. Interest in the engine has been brewing for years, and recently burst over when Bill Gates announced his $23.5 m investment in EcoMotors’ OPOC engine design. The reason for Gates’s, and the world’s, attention is the incredible OPOC engine efficiency. It is claimed that the engines are up to 50% more efficient than a typical internal-combustion engine, while at the same time are smaller and more powerful than Stirling engines. This combination of power and efficiency may make OPOC engines the technology of the future for hybrid cars.

How the OPOC engine works

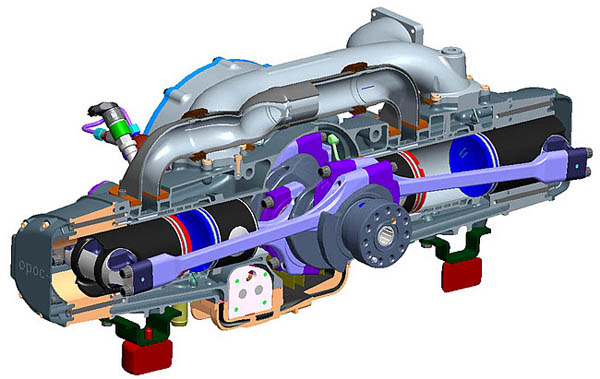

The OPOC engine is an internal combustion engine, so it isn’t emissions-free. The engine, as designed by Ecomotors International, consists of two cylinders, each with two opposing pistons. The two pistons in each cylinder run in opposing directions, and hence there is no cylinder head. This allows a significantly smaller engine to be produced, one that uses only about half the number of parts as a typical four-stroke engine.

In contrast to typical automotive engines, the OPOC is a two-stroke engine. Two-stroke engines make a complete cycle with two piston movements, as opposed to four in four-stroke engines. They accomplish this by combining several steps in each piston movement: intake and exhaust are taken simultaneously during the initiation of the compression stroke and at the completion of the combustion stroke. This allows the engines to output very high power for their weight.

OPOC Engine Developments

Though two-stroke engines are very efficient, engineers have long disregarded them in cars for environmental reasons. Opposed piston diesel engines were popular for a time, and were used in ships, aircraft, and small automobiles. However, the engines had a seemingly unavoidable emissions problem: they release both unburned fuel and oil in the exhaust, creating higher emissions than four-stroke engines. One of the major accomplishments of the Ecomotors team has been to resolve this emissions issue. By eliminating or reducing these emissions, the company has created an engine with much higher power density than typical engines. The company’s website states that the engine creates more than one horsepower per pound. They have also eliminated the need for cylinder caps and drive trains, produced reduced emissions, and provided increased efficiency.

OPOC Engine Efficiency

The engine’s two-stroke design makes it significantly more efficient than conventional engines. The OPOC diesel engine designed by Ecomotors is “30-percent lighter, one-quarter the size, and achieves 50-percent better fuel economy compared with a state-of-the-art, conventional turbo-diesel engine,” as stated on the company website.

The company expects to demonstrate a 100 mpg passenger car by late 2010, which would be a large improvement over today’s hybrid cars. Due to the engine’s small size, it may also end up finding use in hybrid cars, which operate both combustion and electric engines.

Engine Stats

Below, find some specifications of an OPOC engine, the diesel fuel EM100. The engine family is expected to include diesel, gasoline, and ethanol engines.

○ Dry weight: 296 pounds

○ Dimensions: 22.8 x 41.3 x 18.5 (inches), Length x Width x Height

○ Cylinder bore: 100 millimeters

○ 325 horsepower at 3500 rpm.

○ Torque: 664 pound feet at 2100 rpm

○ Power density: 1.1 horsepower/pound

OPOC Engine cost

After reading about the extreme efficiency provided by OPOC engines, readers may begin to wonder how much the cost will be for an OPOC engine. This is a fair question, since other energy efficient engines have proven to be very expensive. Though no price point has been released yet for OPOC engines, there is good reason to expect them to be inexpensive. Unlike electric engines, two-stroke OPOC engines are constructed out of conventional parts. This means that companies won’t need to purchase expensive parts or, worse yet, custom order them. The engine’s small size and simplicity is another advantage: Ecomotors states that the engine has only half the parts of a conventional engine. This saves on expense and labor, and should bring the price down.

The OPOC engine efficiency and simplicity should also make it durable, saving owners maintenance cost in the long-term. After years of false starts in green engine claims, the OPOC engine just may be the real McCoy.