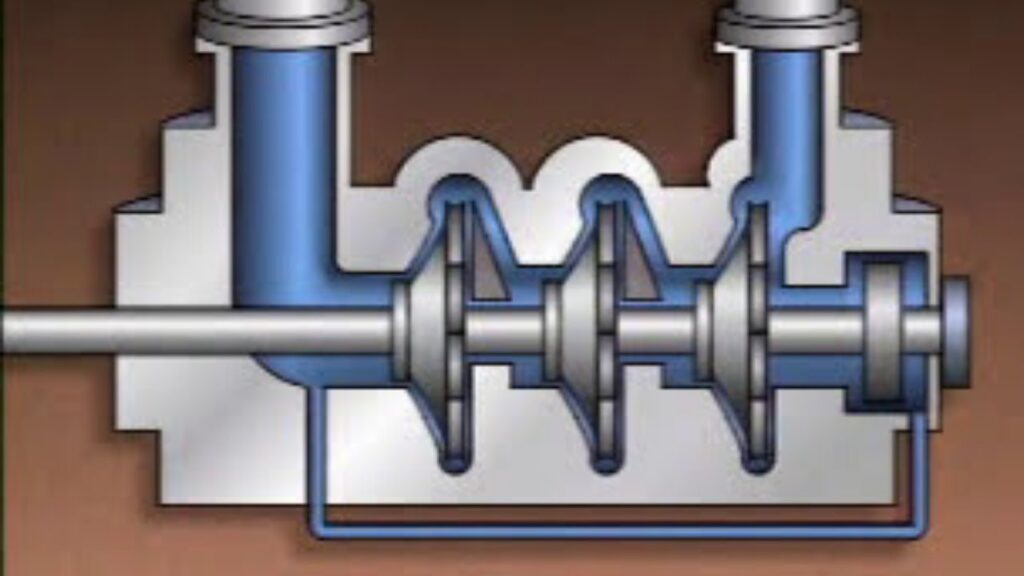

A multistage centrifugal pump is designed with two or more impellers. Depending on the brand and configuration, the impellers might be mounted on the same or different shafts. If high pressures at the outlet are required, impellers can also be connected in series whereas for high flow output, they are typically connected parallel.

Using a multistage centrifugal pump to develop high pressures on a common shaft within the same casing is more economical than a pump with just one impeller. As part of the pump design, channels within the pump casing work by routing the discharge of one impeller to the suction of another.

Water enters the pump and then passes through the multiple impellers in a series, going from the left to right. From there, water passes from the volute that surrounds the volute of one impeller to the suction of the next impeller. Most pumps of this kind are single-stage there are many times when a multistage centrifugal pump is the better solution.