The hydraulic system performs and functions multiple tasks by using a fluid that is pressurized. Putting it the other way it can be said that the pressurized fluid is used to make things work and this process is known as hydraulic system. Although the hydraulic systems work based on the same concept, the purpose of the specific hydraulic system may vary.

The hydraulic system has a variety of applications which makes it usable in different kinds of large and small industrial settings, construction equipment, buildings, and vehicles. Some of the leading users of hydraulic equipment include manufacturing robotics, logging, paper mills, and steel processing.

The power of the pressurized liquid fluids is significant which makes it highly useful in heavy equipment. In the hydraulic system, the pressure that is applied to the fluid at any point of time get transmitted undiminished. The fuel acts on every part of the containing vessel creating power or force which is used to perform repetitive tasks or carry heavy loads.

Using hydraulic system-based equipment is a cost-effective and efficient way of creating movement and repetition. This makes the system the best way to conduct such type of tasks. They are not only dynamic but have a straight forward way of working.

Hydraulic systems are commonly used in different kinds of large and small business settings including buildings, vehicles, and construction equipment. Leading users of hydraulic equipment include paper mills, manufacturing, robotics, steel processing, and logging sectors.

The basic idea that goes behind the hydraulic system is simple and mostly the same. Under this system, the force applied at one point gets transmitted to the other point by using fluid. The fluid used in the process is mostly oil and the force applied gets multiplied in the process.

It has been observed that in case of a basic hydraulic system, the multiplied force is generated in a simple and easy manner. Hydraulic machines the liquid fluid power to perform work; the heavy construction vehicles are one of the common examples of a heavy work machine which utilizes the hydraulic system.

In a heavy construction vehicle, the power is generated by pumping the hydraulic fluid in the hydraulic cylinders and hydraulic motors throughout the machine which gets pressurized according to the resistant present. There are control valves present in the machine which are used to control the fluid directly or automatically. The fluid is then distributed through the tubes, pipes or hoses.

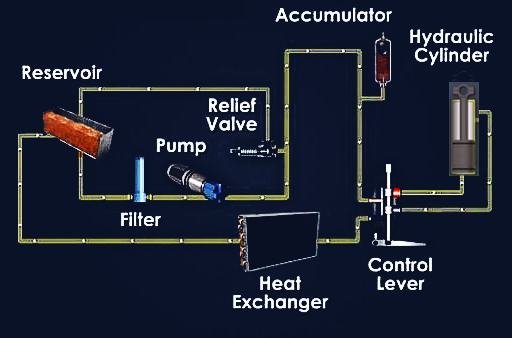

Parts of Hydraulic System

The hydraulic system is made up of different parts which are required for its smooth and effective functioning. The common major components of hydraulic system are hydraulic pumps, control valves, reservoir, and actuators such as motor and cylinder, accumulator, hydraulic fluid, filters, tubes, pipes and hoses.

1. Reservoir

A reservoir plays an important role in the basic hydraulic system, it is the part which holds the excess fluid to accommodate any volume changes which occur due to different reasons. These reasons may be cylinder contraction and extension, extension and contraction due to temperature, and leaks.

A reservoir is designed in such a way so as to assist in the separation of air from fluid. In addition to this, it acts as a heat accumulator to cover up any losses which might have occurred in the system during the peak power usage.

Reservoirs are also known for separating dirt and other particles from oil as the dirt usually gets settled at the bottom. In case of a smaller reservoir, dynamic flow channels are used on the fluid’s return path.

2. Control Valves

Control valves are used to direct the flow of fluid to the actuator. Control valves generally have a spool present inside a steel housing or cast iron. This spool slides to different places in the steel housing, and intersecting channels and grooves to route the fluid as per the spool’s position.

The spool has a neutral central position which is maintained with springs; in this position, the fluid flow is either blocked or returned to the tank. When the spool slides to one side, the fluid gets routed towards the actuator and also provides a return path from the actuator to the tank.

When this spool is moved in the opposite direction, the paths get switched. The directional valves are designed in such a way that they are stackable with one fluid input to supply in all the valves of the stack and one valve for each hydraulic cylinder.

3. Hydraulic Pump

Hydraulic pump, a component of hydraulic system is used to supply fluid to the components present in the hydraulic system. The pressure gets created in the system in reaction to the load applied. These pumps are known to have a power density that is about ten times greater than the electric motor.

These are either powered by an engine or electric motor and connected through belts, gears, or flexible elastomeric coupling to reduce the vibration. The common types of hydraulic pumps to hydraulic machinery applications include vane pump, gear pump, radial piston pump, and axial piston pump.

4. Actuators

Actuators consist of hydraulic cylinder, hydraulic motor, brakes, and hydrostatic transmission. A hydraulic motor is a pump plumbed in reverse; they have axial configuration and use swashplates for maintaining accurate control levels. These are frequently driven by numerous hydraulic pistons acting in a sequence.

5. Accumulator

One of the components of the hydraulic system is an accumulator. This is a common part of the hydraulic machinery which functions to store energy by utilizing pressurized gas. There are different types of accumulator; one type is a tube consisting of a floating piston.

While one side of the piston consists of the charge of pressurized gas, the other side is fluid. A shock absorber for the hydraulic circuit or backup power for the brakes or steering is some of the examples of the accumulator.

6. Hydraulic Fluid

Hydraulic fluid popularly known as the tractor fluid acts as a life of the hydraulic circuit. Hydraulic fluid is mainly petroleum with additives. Depending on the applications, some machines require fire-resistant fluids. In many factories which prepare food items use water or edible oil as hydraulic fluid for safety measures.

7. Filters

Filters are an important part of the hydraulic system as they remove the unwanted particles from the fluid. Mechanical components continuously produce metal particles which are required to be removed in addition to the dirt.

8. Tubes, Pipes, and Hoses

Hydraulic tubes are basically steel precision pipes which are manufactured for hydraulics. When these tubes are unavailable that is when hydraulic pipes enter the picture. These pipes are generally used for low pressure. When both the pipes and tubes are unavailable, hoses are put to use in the hydraulic system.