Over the years, manual transmission vehicles have had two main types of clutch movement: mechanical and hydraulic. Many older cars use a mechanical or cable system, whereas almost all modern cars use a hydraulic clutch.

It’s pretty common for classic cars to be fitted with a hydraulic clutch conversion kit to modernize them. It’s less appealing for those who want to keep their car as original as possible.

WHAT IS A MECHANICAL CLUTCH?

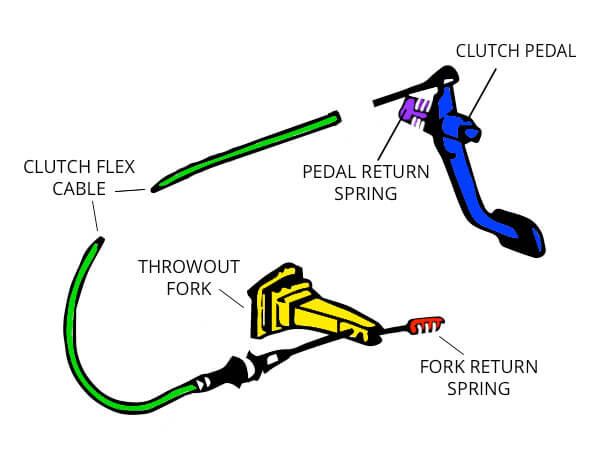

Mechanical clutches (or cable-actuated clutches) use a cable to move the clutch disc. They preceded hydraulic clutch systems and were commonly used on cars up until the 1990s. Today, it’s very rare to see a car with a mechanical clutch, though they’re often used on motorcycles.

How Does a Mechanical Clutch Work?

A mechanical clutch is a pretty simple system. A steel cable connects the clutch pedal directly to the clutch assembly. Pressing (or actuating) the pedal moves the cable. This moves the clutch fork, which actuates the clutch throwout bearing. This then disengages the clutch plate.

The lack of hydraulic assistance often makes a mechanical clutch’s pedal weight feel heavier. Even those who grew up driving modern manual transmission cars may find that mechanical clutch cars take some getting used to. The direct connection of a mechanical clutch means the driver will typically feel more engagement when shifting.

WHAT IS A HYDRAULIC CLUTCH?

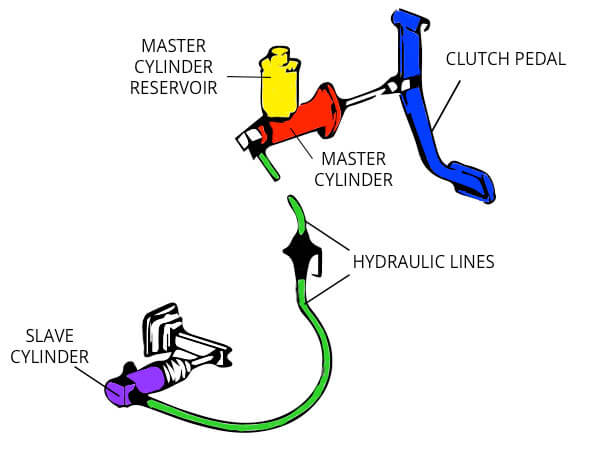

A hydraulic clutch uses hydraulic fluid instead of a cable to move the clutch disc. It relies on reservoir cylinders to control pressure in relation to how the clutch pedal is depressed. Most cars made from the ‘90s onward have hydraulic clutches.

How Does a Hydraulic Clutch Work?

A hydraulic clutch uses fluid to actuate a hydraulic piston. This fluid-filled tube looks sort of like the hydraulics you’d see on a hood strut or screen door.

The piston then engages or disengages the clutch through a series of connections. The hydraulic fluid is often called “clutch fluid.” However, it is actually the same as brake fluid. It’s stored in the clutch master cylinder.

The clutch master cylinder converts the pressing of the clutch pedal into hydraulic pressure. This power is then transferred to the clutch slave cylinder. A rod extends from the slave cylinder, actuating the clutch fork. The clutch fork then moves the clutch release bearing. This, in turn, releases the clutch pressure plate, disengaging the clutch.

HYDRAULIC VS MECHANICAL CLUTCH COMPARISON

Before looking at the conversion process, let’s see how hydraulic and mechanical clutches differ. The advantages of a modern hydraulic system make the switch worth it for some drivers. Easier, smoother clutch pedal travel is a major benefit of upgrading to a hydraulic clutch. Cruising can be more enjoyable when you don’t have to work a stiff, rougher-feeling clutch.

However, some purists favor keeping things original with the older cable-actuated configuration. If you enjoy the vintage feel and old-fashioned engagement of a manual clutch, it’s best to leave it as-is.

MECHANICAL CLUTCH PROS AND CONS

| Pros | Cons |

|---|---|

| Old-school pedal feel | Requires adjustment and lubrication |

| Simple system | Heavy clutch pedal |

| Cable can strain/break |

Mechanical clutches offer a couple of benefits over hydraulic clutches. One is that some drivers prefer the feeling of a cable-actuated clutch. They say that it feels more engaging to drive. Another is the overall simplicity of the system. It can be easier to maintain and repair as needed.

There are some drawbacks to mechanical clutches though. They require adjustment and lubrication over time. While any type of clutch can have issues, a mechanical clutch’s cables can strain and snap. That can be tough to repair for those without experience.

HYDRAULIC CLUTCH PROS AND CONS

| Pros | Cons |

|---|---|

| Easier pedal press | Requires bleeding |

| Smoother engagement | Repairs can be costly |

| No adjustment needed |

Hydraulic clutches are favored by drivers who want a modern set-up. Most importantly, they offer an easier and smoother clutch pedal feel. Unlike mechanical clutches, they don’t require adjustment (as long as there’s clutch fluid). Hydraulic clutches self-adjust automatically.

A downside to hydraulic clutches is the potential for leaks. While minor repairs are generally easier with a hydraulic clutch, a leak can be a major and expensive issue. The clutch master cylinder and slave cylinder can also be frustrating to work with.

Another minor downside is that you’ll have to bleed a hydraulic clutch occasionally. Usually once every few years. Fortunately, this is an easier process than bleeding brakes and can be handled by one person if needed.