By using casting process along with some specifications the replica of an object is made, which is known as pattern.

Different types of patterns are used in the casting process which depends upon the configuration of casting they are divided into 8 types. They are:

- Single piece pattern

- Cope and drag pattern

- Loose piece pattern

- Sweep pattern

- Skelton pattern

- Match plate pattern

- Gated pattern

Single piece pattern

The single piece patterns are used when the job is very simple. In this type of methods there are no withdrawal problems.

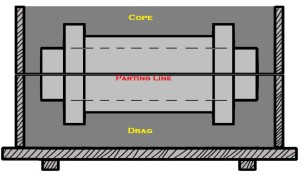

Cope and drag pattern

The drag and cope halves of a split pattern are separately fixed on two match plates. The drag and cope are finished separately and carried together to produce the complete mould.

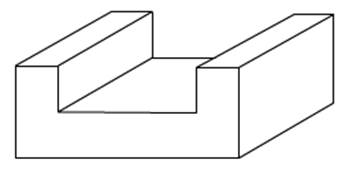

Loose piece pattern

Loose piece patterns are used when the withdrawal of the pattern is not possible from the mould.

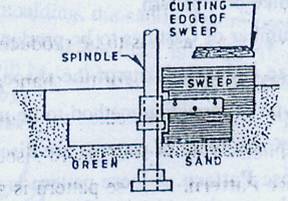

Sweep pattern

Sweep patterns are normally used made up of wood. Mainly this pattern is used in the large casting process and used to prepare a mould out of a pipe like material. Sweep means section that rotates about an edge to yield circular section.

Skelton pattern

Skelton pattern are made up of wooden frames drawing the shapes of the casting. The Skelton patterns are used to lead the mold for a great casting and simple geometrical forms.

Match plate pattern

The two halves are mounted on the both sides of a match plate, to conform the contour of the parting surface. The match plates are accurately placed on the drag and on the cope by using locating pins. For small casting several patterns can be mounted on the same match plate.

Gated pattern:

In this pattern one or more than one loose pattern with attached gates and runners provides a channel through which the molten metal can flow from the pouring sprue to the mould cavity.

This pattern is frequently set on a follow board conforming to the parting surface of the mould. The follow board helps in an easy removal of the pattern after the mould has been prepared.

Different types of pattern allowances are seen, some of them are:

- Shrinkage allowances

- Draft allowances

- Machining Allowances

- Shake Allowances

- Distortion Allowances

Shrinkage Allowances:

Shrinkage allowances are observed during the time of solidification and cooling in the mould. For the instance, the casting becomes smaller than the mould cavity and the pattern. So to avoid the shrinkages, the pattern and the mould must be made large than the casting. The compensation amount for the shrinkage is known as shrinkage allowances.

Normally shrinkage varies not only with the material but also with the thickness, shape, temperature of casting and the temperature of the mould.

Shrinkages that are observed in the casting metals:

| S.No | Type of material | Amount of shrinkage |

| 1 | Aluminum | 1.65 |

| 2 | Aluminum Alloy | 1.30 to 1.60 |

| 3 | Brasses | 1.30 to 1.55 |

| 4 | Bronze | 1.05 to 2.10 |

| 5 | Grey cast Iron | 0.55 to 1.00 |

| 6 | Malleable Cast iron | 1.00 |

| 7 | Magnesium | 1.80 |

| 8 | Manganese steel | 2.60 |

| 9 | Steels | 2.00 |

| 10 | Tin | 2.00 |

| 11 | White cast Iron | 2.10 |

| 12 | Zinc | 2.60 |

Basically special scales and rules are used by the pattern makers with the help of “contraction rule”. They are provided with the necessary allowances and it is slightly longer than the ordinary rule of the same length. Different types of contraction rules are available for different casting metals. Mainly single ruler is used on each side of these two scales.

| S.No | Material used and place of use | Contraction Rule |

| 1 | Cast iron , part of thin cast iron | +8/1000 |

| 2 | Cast iron products of high strength, part of thin cast steel | +9/1000 |

| 3 | Cast iron products of high strength, part of thin cast steel | +10/1000 |

| 4 | Aluminium alloys , cast steel, bronze | +12/1000 |

| 5 | High tension brass and cast steel | +14/1000 |

| 6 | Cast steel | +16/1000 |

| 7 | Large Cast Steel | +20/1000 |

| 8 | Large cast iron | +25/1000 |

Contraction rule standards:

Draft Allowance:

During the removal of pattern from the sand mould there is a chance of damaging the edges of the mould. The vertical face of the pattern is in continuous contact with the sand, which leads to damage the mould cavity. To reduce the changes the vertical face of the pattern are always tapered from the parting lines. The draft allowances are expressed in mm per metre on a side or in degrees.

Draft Allowances depends upon following factors:

- Casting shape

- Casting Depth

- Moulding methods

- Material used for moulding.

The size of the draft must be 5 to 30 mm per meter or an average of 20 mm per meter.

Machining Allowance:

The casting designed to be machined; the casts that remain oversized are later resized by using the required dimensions. To perform the machining operation the casting work piece must be made extra thicker, and this process is also known as machining allowances.

Machining allowances are given due to following reasons:

During the time of the heat treatment the casting gets oxidised inside the mould. At that instance the required formed scale is removed. So machining is used to remove the surface roughness, dirt, slag and other imperfections from the casting. So the machining is done to obtain exact dimensions on the casting.

Depends upon the following factors:

Machining Process:

- Compare with the grinding process and turning machining process, grinding removes less metal

Characteristics of metal:

- Non – ferrous and ferrous metals are soft or hard and easily machinable

- Ferrous metal is to get oxidised and Aluminium metal that does not oxidise

Casting Method to use:

- Centrifugal casting needs more allowances on the internal side.

- For die casting it needs little machining, and for sand castings requires more.

Shape and size of the casting:

- For long castings it requires greater allowances.

- Thicker section must be solidifying late and then impurities tend to collect there.

- This requires more machining allowances.

Degree of finish required:

- High degree of finishing requires more machining allowances.

| Material | Types of metal and alloys | Machining allowances |

| Cast iron | Large size casting | 10.0 |

| Cast iron | Medium size casting | 3.0 |

| Cast Steels | Large size casting | 12.0 |

| Cast Steels | Medium size casting | 4.3 |

| Non- ferrous material | Large size casting | 5.0 |

| Non- ferrous material | Medium size casting | 1.5 |

Shaking Allowances:

Shaking allowances is also known as the rapping allowances. If the pattern is shaken for stress-free removal, the mould cavity, hence the casting is somewhat increased in size. Coming to the average sized casting the allowances are to be overlooked. In large sized and precision castings shrinking allowances are too considered. Mainly these depend upon the previous experiences.

Distortion Allowances:

Distortion allowances are also known as camber allowances. Based upon the size, type of metal, shape they tend to twist during cooling period and the cooling speed. In different parts of casting uneven shrinkages are shown. We need to expect the twist amount according to which we need to make the pattern, this is known as camber.

Pattern material:

- Normally the pattern materials are metals, wood and plastics. Most commonly used pattern material is wood.

- There is a disadvantage of using the wood, as we can observe the absorption of moisture in the wood.

- The absorption of the moister results to distortion and change of dimensions are seen.

- The selection material depends upon the

1. Size of the casting

2. No of castings performed on the pattern

3. Dimensional accuracy should be required

- For large casting mainly wood must be preferred as a pattern material.

- Due to the smooth surfaces and ductility, metal patterns are extensively used for large scale casting production and for closer dimensional tolerances.

- Through the material such as brass, cast iron, etc. Subsequently, for the pattern materials like white metal and aluminum are commonly used. These are light plus, can easily work and also are corrosion resistance

- White metals have very small shrinkage and they can use for making the additional patterns without thinking about the double shrinkage allowances.

- Most metal patterns are cast in sand molds from a master wood pattern, which provides the double shrinkage allowances.

- Plastics are suitable for the pattern materials because of their low weight, easier formability, durability and smooth surface.

- They do not absorb moisture and their dimensions are stable and cleaned easily.

- The plastic pattern can be done in sand, clay molds or molds that are made up of plaster of paris.

- With the proper combination it is possible to obtain a no shrink plastic material, and as such double shrinkage allowances may not be required.