Pressing the powders into desired part shape as closely as possible to final dimensions

Powders are compacted using high pressure.

· Degree of pressure required depends upon

ü Required density of final product

ü Ease with which powder particles will weld together.

· Compacting processes are

a) Die pressing

b) Roll pressing

c) Extrusion

Die pressing

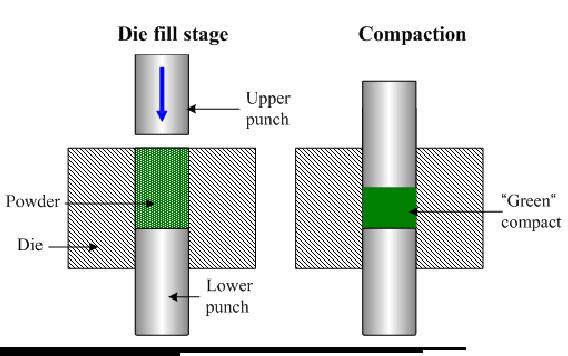

➢It consists of upper punch and lower punch as shown in fig.

➢Powder is filled on the space above lower punch.

➢Upper punch applies high pressure to the powder.

➢Finally the green compact powder is received as shown in fig.

Die pressing

Roll pressing

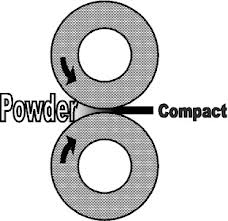

➢ Two rolls of appropriate sizes are used.

➢Stream of powder is guided, so that the rolls are able to apply the necessary compacting pressure in a continuous sequence.

Roll pressing

Extrusion method

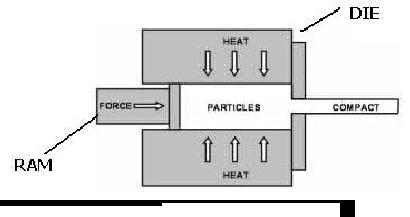

➢Ram is used for applying force.

➢ Two dies are used for achieving proper thickness.

➢As seen in the figure the green compact is received which is further send for sintering process.

Extrusion