Introduction

USM is mechanical material removal process or an abrasive process used to erode holes or cavities on hard or brittle work piece by using shaped tools, high frequency mechanical motion and an abrasive slurry. USM offers a solution to the expanding need for machining brittle materials such as single crystals, glasses and polycrystalline ceramics, and increasing complex operations to provide intricate shapes and work piece profiles. It is therefore used extensively in machining hard and brittle materials that are difficult to machine by traditionalmanufacturing processes. The hard particles in slurry are accelerated toward the surface of the work piece by a tool oscillating at a frequency up to 100 KHz – through repeated abrasions, the tool machines a cavity of a cross section identical to its own.

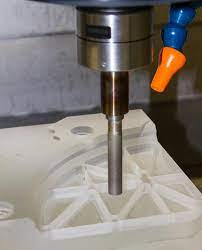

Figure: Schematic of ultrasonic machine tool

USM is primarily targeted for the machining of hard and brittle materials (dielectric or conductive) such as boron carbide, ceramics, titanium carbides, rubies, quartz etc. USM is a versatile machining process as far as properties of materials are con cerned. This process is able toeffectively machine all materials whether they are electrically conductive or insulator.

For an effective cutting operation, the following parameters need to be carefully considered:

• The machining tool must be selected to be highly wear resistant, such as high-carbon steels.

• The abrasives (25-60 µm in dia.) in the (water-based, up to 40% solid volume) slurry

Includes: Boron carbide, silicon carbide and aluminum oxide.

Applications

The beauty of USM is that it can make non round shapes in hard and brittle materials. Ultrasonically machined non round-hole part is shown in Figure 11.

Figure: A non-round hole made by USM

Advantage of USM

USM process is a non-thermal, non-chemical, creates no changes in the microstructures, chemical or physical properties of the work piece and offers virtually stress free machined surfaces.

• Any materials can be machined regardless of their electrical con ductivity

• Especially suitable for machining of brittle materials

• Machined parts by USM possess better surface finish and higher structural integrity.

• USM does not produce thermal, electrical and chemical abnormal surface

Disadvantages of USM

• USM has higher power consumption and lower material-removal rates than traditional

Fabrication processes.

• Tool wears fast in USM.

• Machining area and depth is restraint in USM.