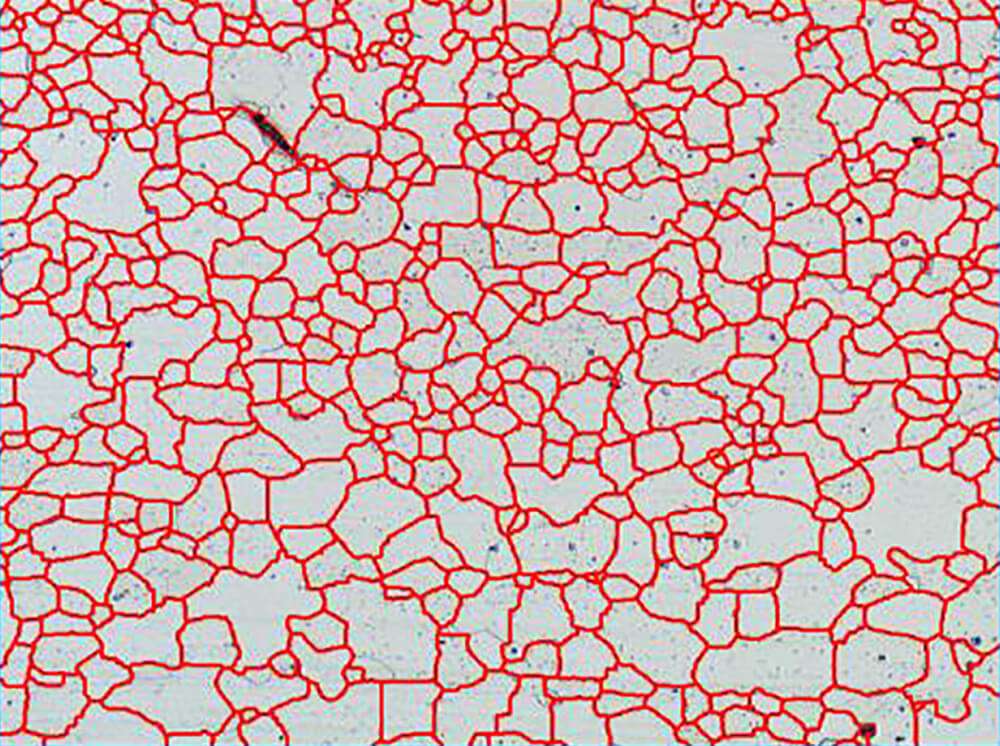

The grain size is often determined when the properties of a polycrystalline material are under consideration. In this regard, there exist a number of techniques by which size is specified in terms of average grain volume, diameter, or area. Grain size may be estimated by using an interceptmethod, described as follows. Straight lines all the same length are drawn through several photomicrographs that show the grain structure. The grains intersected by each line segment are counted; the line length is then divided by an average of the number of grains intersected, taken over all the line segments. The average grain diameter is found by dividing this result by the linear magnification of the photomicrographs.

Grain size is measured with a microscope by counting the number of grains within a given area, by determining the number of grains that intersect a given length of random line, or by comparison with standard charts. The average grain diameter D can be determined from measurements along random lines by the equation

Grain size is measured with a microscope by counting the number of grains within a given area, by determining the number of grains that intersect a given length of random line, or by comparison with standard charts. The average grain diameter D can be determined from measurements along random lines by the equation

where L is the length of the line and N is the number of intercepts which the grain boundary makes with the line. This can be related to the ratio of the grain-boundary surface area S to the volume of the grains, V, by the equation

where 1 is the total length of grain boundary n a random plane of polish and A is the total area of the grains on a random plane of polish. A very common method of measuring grain size in the United States is to compare the grains at a fixed magnification with the American Society for Testing and Materials (ASTM) grain-size charts. The ASTM grain-size number n is related to N ,

the number of grains per square inch at a magnification of 100X by the relationship

the number of grains per square inch at a magnification of 100X by the relationship

Table shown compares the ASTM grain-size numbers with several other useful measures of grain size.