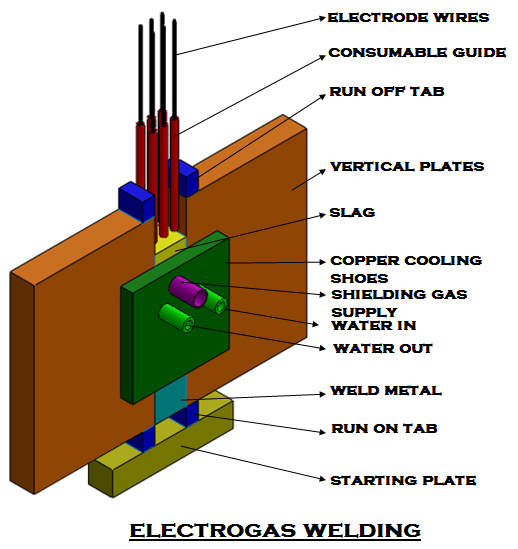

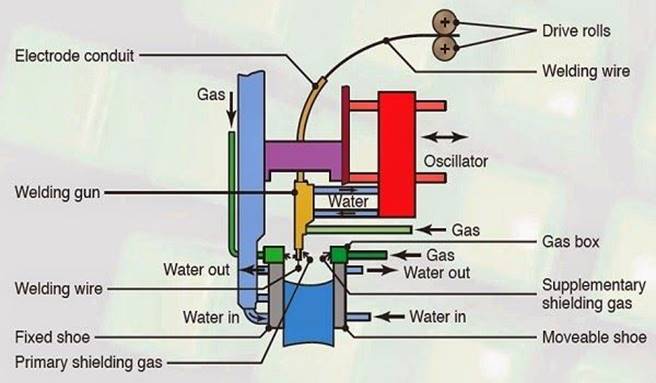

Electrogas welding (EGW) is an vertical positioned arc welding process, is used for welding the edges of sections vertically and in one pass with the pieces placed edge to edge (butt joint). It is classified as a machine-welding process, because for its operation requires special equipment. The weld metal is deposited into a weld cavity between the two pieces to be joined. The space is covered by two water-cooled copper dams(shoes) to prevent the molten slag from running off; mechanical drives move the shoes upward.

Schematic illustration of the electrogas welding process.

One or more electrodes are fed through a conduit and a continuous arc is maintained by flux-cored electrodes at up to 750 A or solid electrodes at 400 A. Power requirements is 20 kW. Shielding is done by means of an inert gas, such as argon or helium depending on the type of material being welded. The gas may be provided either from an external source, from a flux-cored electrode or from both the sources. The equipment of electrogas welding is reliable and training an operator is easy. Weld thickness is between 12 mm to 75 mm on steels, titanium and aluminum alloys.

Electrogas welding process is used in the construction of bridges, pressure vessels, thick-walled and large-diameter pipes, storage tanks, submarines and ships.