· The kinetic energy of combustion gas is converted to mechanical power by the its impulse or reaction with a series of blades arranged around the circumference of a wheel or cylinder

· Stationary blades / guide blades act as nozzles and they convert fluid pressure into kinetic energy. The following rotating blades convert kinetic energy into useful work.

· Axial turbines have low pressure drop per stage and higher mass flow rate compared to radial turbines.

· The flow stream lines through the blading’s are nearly parallel to the shaft axis

· The flow stream lines through the blading’s are nearly parallel to the shaft axis.

· Flow enters axially and discharges almost axially.

· The blade passages converge from inlet to exit, and hence the flow accelerates.

· Blade profile is thicker at the inlet and thinner at the exit.

· Due to density variation from inlet to exit, the turbine end walls have flare with flow area increasing from inlet to exit.

Axial Turbine Stage

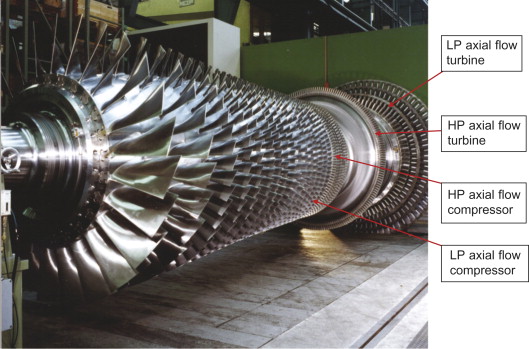

Multistage Axial Turbine

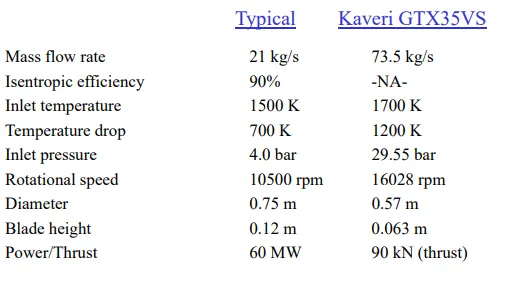

Axial Turbine Specification