· The flow enters a three-dimensional impeller axially through an inlet duct. The impeller may be preceded by a row of inlet guide vanes.

· The impeller through its blades imparts velocity and pressure to the gas which flows in radial direction.

· The rise in pressure takes place due to the centrifugal action of the impeller and diverging passages of the downstream diffuser and / or volute

· Vaned or vaneless diffuser with volute are provided to convert kinetic energy at impeller exit into static pressure at compressor discharge.

· Centrifugal compressors are use d to produce large pressure ratios.

· A single stage centrifugal compressor may have typical pressure ratio of about 4:1. Some test compressors are designed for pressure ratio up to 8:1.

· Centrifugal compressors are suitable for low specific speed, high pressure ratio per stage and low mass flow rate applications.

· Based on application, the centrifugal compressors can be either single stage or multistage type.

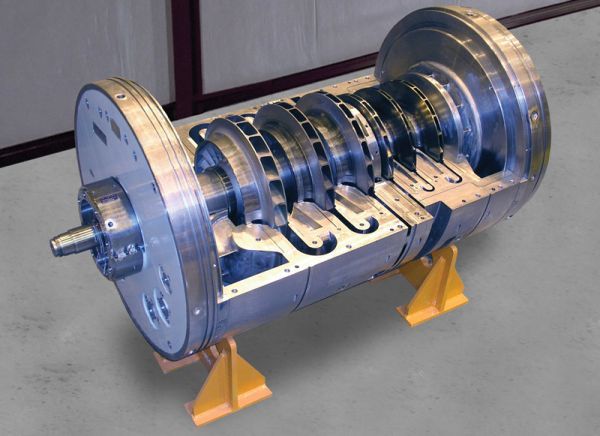

Components of a centrifugal compressor

· Impeller

· Diffuser

· Casing

· Shaft

Application of centrifugal compressor

· Gas turbine

· Turbocharger

· Process industry

![]() Gas compression

Gas compression

![]() Oxygen plants

Oxygen plants

![]() Instrument air

Instrument air