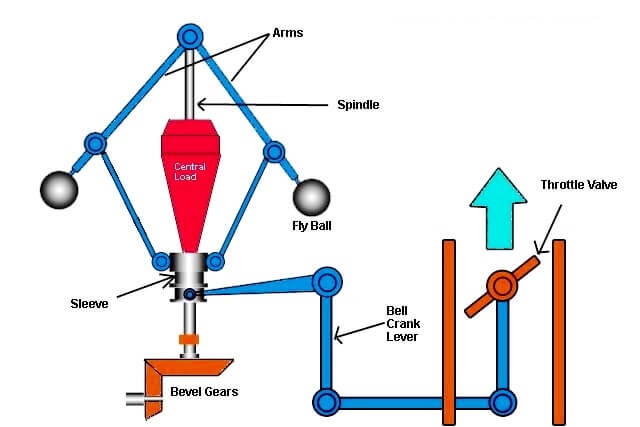

An isochronous governor having structure which provides a pressure force to compensate for the relative decrease of governor spring force with respect to flyweight force as engine load increases, thereby allowing the engine controlled by the governor to maintain operation at a constant speed under varying load high idle, no load speed, at all times. In a turbocharged engine, inlet manifold air pressure may be utilized to produce the force. The air pressure directly related to engine load acts upon a small piston and the resulting pressure force, approximately equal to the difference between the spring and the flyweight forces as engine load increases, acts upon the governor structure to properly position the fuel pump rack to maintain a desired engine speed. Engine oil pressure may alternatively be utilized to provide the required pressure force, and a second lever, positioned by the fuel pump rack, serves to preload a relief valve in the engine oil pressure system, thereby controlling the oil pressure in the system as a function of the fuel rack position.

A governor is said to be isochronous when the equilibrium speed is constant (i.e. range of speed is zero) for all radii of rotation of the balls within the working range, neglecting friction. The isochronism is the stage of infinite sensitivity.

Let us consider the case of a Porter governor running at speeds N1 and N2 r.p.m.

For isochronism, range of speed should be zero i.e. N2 – N1 = 0 or N2 = N1. Therefore from equations above, h1 = h2, which is impossible in case of a Porter governor. Hence a Porter governor cannot be

isochronous.

Note : The isochronous governor is not of practical use because the sleeve will move to one of its extremepositions immediately the speed deviates from the isochronous speed.