brief procedure about operation of vacuum pumping system. The step by step procedure will ensure the proper functioning of the pump. This procedure is developed based on the reviews and experience of technicians of vacuum pump.

Steps:

1. Switch ON mains

2. Switch ON Rotary Pump (RP)

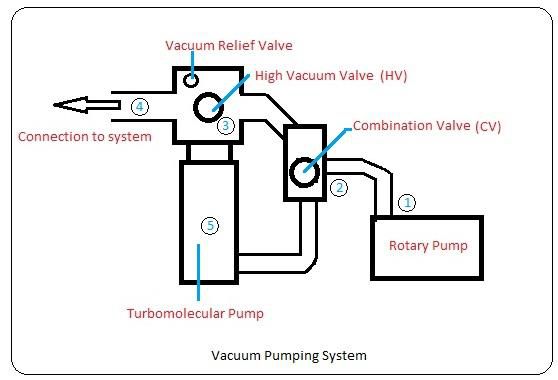

3. Make sure Combination Valve (CV) is in CLOSE position and allow the pump to develop vacuum of 0.05 mbar. (pumping circuit is 1-2-3, see the figure)

4. Position CV to backing position (GH1/PR1) and allow the pump to develop vacuum of 0.05 mbar. (pumping circuit is 1-2-5)

5. Position CV to Roughing Position (GH2/PR2) and allow the pump to develop vacuum of 0.05 mbar. (pumping circuit is 1-2-3-4)

6. Now to develop high vacuum, First position the CV to close and immediate to backing position.

7. Now switch on the turbo pump.

8. Once the speed is achieved, Position the CV to roughing position (GH2/PR2) and allow the pump to develop vacuum of 0.05 mbar.

9. Again put CV to closing position and immediately keep in backing position (GH1/PR1)

10. Now open the high vacuum valve (Gate Valve) (pumping circuit is 1-2-5-3-4)

11. After 5 min, switch ON penning gauge to show the reading. Always keep in mind not to keep it in ON condition throughout running. But switch it on when it is required to take reading otherwise keep it OFF.

Notes:

In Old Vacuum system with turbo pump (VS-114DT), company-HindHigh vacuum system), roughing will requires gauge in GH2 and backing requires gauge in GH1 condition while new vacuum system will not requires these.

Old vacuum system with turbo pump (VS-114DT) requires setting gauge position to GH1 & GH2 while new vacuum system with turbo pump (VS-114T) will not require to do so.

Always operate CV and high vacuum valve gradually

Always put high vacuum valve in CLOSE position while doing Roughing.

Always keep in mind to have backing Position (GH1/PR1) while using turbo Pump

In case of power failure during running condition, immediately shut/close all the parts of system like gauges, CV, and high vacuum valve.

In case power takes very little time (2 min or less) to come back, there is no need to do Roughing again, and if takes long more than 30 min, it is mandatory to do Roughing again. And do the same procedure again which otherwise required for starting pump.

Foreline Trap: If sufficient vacuum is not obtained at any time, CLOSE the CV valve and allow to having vacuum of 0.05 mbar. Open GAS BALLAST plug from ROTARY PUMP and then switch ON the foreline Trap Heater for 30 minutes to dry out oil/moisture trapped in rotary pump.

Shutdown procedure:

1. Switch OFF penning gauge

2. Close high vacuum valve (gate valve)

3. Switch OFF turbo Pump

4. Wait for 10 min.

5. Close CV valve and then

6. Switch off rotary valve