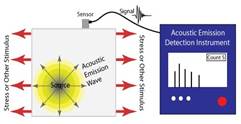

Acoustic Emission (AE) refers to the generation of transient elastic waves produced by a sudden redistribution of stress in a material. When a structure is subjected to an external stimulus (change in pressure, load, or temperature), localized sources trigger the release of energy, in the form of stress waves, which propagate to the surface and are recorded by sensors. With the right equipment and setup, motions on the order of picometers (10 -12 m) can be identified. Sources of AE vary from natural events like earthquakes and rockbursts to the initiation and growth of cracks, slip and dislocation movements, melting, twinning, and phase transformations in metals. In composites, matrix cracking and fiber breakage and debonding contribute to acoustic emissions. AE’s have also been measured and recorded in polymers, wood, and concrete, among other materials.

Detection and analysis of AE signals can supply valuable information regarding the origin and importance of a discontinuity in a material. Because of the versatility of Acoustic Emission Testing (AET), it has many industrial applications (e.g. assessing structural integrity, detecting flaws, testing for leaks, or monitoring weld quality) and is used extensively as a research tool.

Acoustic Emission is unlike most other nondestructive testing (NDT) techniques in two regards. The first difference pertains to the origin of the signal. Instead of supplying energy to the object under examination, AET simply listens for the energy released by the object. AE tests are often performed on structures while in operation, as this provides adequate loading for propagating defects and triggering acoustic emissions.

The second difference is that AET deals with dynamic processes, or changes, in a material. This is particularly meaningful because only active features (e.g. crack growth) are highlighted. The ability to discern between developing and stagnant defects is significant. However, it is possible for flaws to go undetected altogether if the loading is not high enough to cause an acoustic event. Furthermore, AE testing usually provides an immediate indication relating to the strength or risk of failure of a component. Other advantages of AET include fast and complete volumetric inspection using multiple sensors, permanent sensor mounting for process control, and no need to disassemble and clean a specimen.

Unfortunately, AE systems can only qualitatively gauge how much damage is contained in a structure. In order to obtain quantitative results about size, depth, and overall acceptability of a part, other NDT methods (often ultrasonic testing) are necessary. Another drawback of AE stems from loud service environments which contribute extraneous noise to the signals. For successful applications, signal discrimination and noise reduction are crucial.