Internet environment and internet based tools enable numerous opportunities of establishing new enterprises even without any actual, physical office. Such enterprises are already functioning in many services, e.g. language, banking, trading, to full extent. This is also true in various engineering activities. Such an environment is also beneficial in case of multinational companies, since it enables new, powerful means of communication throughout the world as a part of their distributed collaboration environment, as well as in small firms where the primary benefit lies in possibilities of the joint virtual collaboration.On the other hand, emerging design and production systems are characterised by their atomisation. This is true for huge international enterprises, establishing their branch offices and production units in expenses and resources optimized manner. And it is also true in case of specialised small and micro enterprises. Namely, due to high tech product complexity, the latter can be competitive mostly in combined efforts. Such companies operate in a distributed production and design environment. It should be also stated that the role of the innovative design in economic growth of companies is crucial. Therefore, a distributed development environment must introduce a new working paradigm, adapted to permanent design innovation and sustainable product development. The proposed chapter deals with the On-line engineering office (OLEO) concept. Its basis and structures will be discussed in detail, and several possible scenarios and advantages will be presented to illustrate the proposed concept. It is our belief that such a concept can importantly support not only SMEs but micro companies as well. Particularly in small economies it can be difficult to maintain and develop prosperous small specialised engineering business, thus it is necessary to spread such an enterprise over the borders. And the proposed concept seems to be a feasible solution.

Contemporary information and communication technologies (ICT) enable different means and methods for e-collaboration. The key requirements for implementation of the design and development collaboration framework are functional and resource integration; synchronous and asynchronous communication; data, file and document management; project management; and common cooperation space in a distributed environment. Besides, the ICT platform has to assure a high level of privacy, safety, and reliability, which all are essential building blocks of the OLEO. It relies on service oriented architecture and virtual portal technology and on virtual coordination unit in organisational sense. The crucial advantage of the proposed concept is that it is lean. Lean companies are well known organisational issue. Large companies tend to “leanify” their production. And let diverse costly tasks outsource. In this context the particular OLEO consists of its basic competence, e.g. space trusses design, special gearing design, PLC planning and deployment, automatic production line design, etc. Necessary regulatory and financial tasks are outsourced. Despite its specialisation, such a business needs particular knowledge or routine at its boundaries. Or a design project appears to exceed human resources. It is efficient to find other specialists, provided a common platform can be established. No employment is needed, no additional administration, just necessary human force for the limited time period. Of course, such cooperation is based on particular competences of the involved partners. This can include human specialisation, software tools and machine operation.The OLEO is therefore characterised as a web based on-line accessible engineering facility with sufficient competence and abilities in at least one main engineering development and design area and ability to form or adjoin another corresponding facilities based on their and collected competence. Functionalities then depend on design and development tasks that the OLEO is competent in. The proposed formation uses an adaptable ad/hoc networked development environment collecting human expertise, engineering tools, web tools and methods, data and knowledge bases, and communication and collaboration tools.

Mechatronic product development

Mechatronic product development is centred on discipline-specific specialisation of sub- processes, methods and tools, and the apparent need for cross-disciplinary harmonisation. The later is a prerequisite for reliable project assessment and control. It is also a foundation for efficient cooperation of individual specialists, teams and disciplines. It is a challenging task within a cross-enterprise or individual OLEOs cooperation leading to efficient task solution. Problem discussed in this chapter relates mechatronic product or system design and development in small and medium size enterprises (SME), which have only limited resources to develop such products. However, their market position and competitiveness strongly depend on new innovative, creative goods, which basically consist of a mechanical structure, electronic and micro-processing devices, as well as programs or even intelligent software for the implementation of the operations control. This means that the complexity of the mechatronic product development, design and manufacturing requires a number of highly competent and knowledgeable subjects in different fields. It also implies usage of the newest methods, tools, and variety of data and knowledge bases. At last, results of fundamental and applied research are indispensable in development of new artefacts. On the other hand, SMEs are performing excellently in their specialised domain. To become and remain in such state they should continuously optimise their development and work systems to their production. Problems are lack of knowledge, experience and man-power in other fields, e.g. development of promising new products or systems, technologies, factory automation, etc. Thus, questions raised here from the SMEs viewpoint are

1. about definition of a new product itself and its production technology and

2. search for competent developers and developing tools.

Yet another aspect in engineering design is that designers are dealing with uncertainty starting from inexact specifications and only the degree of their competence makes possible convergence towards an improvement or new product. It is necessary to gain new information, to decide upon and build a model and possibly incorporate this in a particular design.

This could be regarded as innovation process. Only LMC have sufficient resources enabling continuous innovation. In order to explore mechatronic product development, several aspects should be discussed. First of all the vital resources of the development process, represented in Fig. 1, should be debated. As one can see in the figure, the first are people with their particular skills and knowledge, who are trained for special tasks and who might be certified to do some (design) tasks and not less important, they should be properly motivated. Then, there are particular tools and equipment, mostly computer software and hardware, enabling such tasks. And at last, each design process is project based and self contained are procedures and methods defining interrelationships between tasks necessary for the project to converge to a mechatronic product.

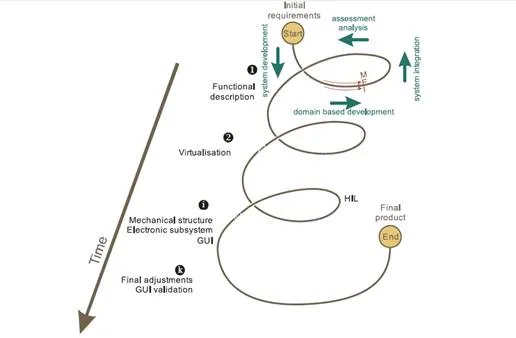

Another aspect is the design and development process, gradually proceeding in iterative manner from initial requirements to a mature product, as illustrated in Fig. 2. Design cannot rely only on creativeness and innovativeness. Due to complexity of intended artefacts, mechanical design systematic has been developed and put into practice especially in Germany in the second half of the last century, which is thoroughly founded in work of Pahl and Beitz from 1980 and gradually improved up to day (Pahl and Beitz, 2007). Since then, other, more abstract approach, aiming to mathematically formulate and analyse mappings from the customer needs, through the functional structure up to the design and the process domain following axiomatic rules was developed by Suh in 90-ties (Suh, 2001). Yet another approach, gaining importance, is TRIZ – Theory of inventive problem solving. TRIZ was developed mainly using knowledge acquired from engineering patents awarded in all engineering domains and is based on the concept that every superior invention is the result of resolving a contradiction and that technical systems follow generic tendencies throughout their existence, which have been named as the laws of technical system evolution (Altshuller, 1984). TRIZ aims to problem solving in computer aided innovation (Leon, 2009 and Verhaegen et al., 2009). However, a new paradigm was necessary for mechatronic system design. Mechatronic systems could be defined as a composition of sensors and actors in a mechanical core, whereas informational structure makes possible its process(es). At first, mechatronic system development was organised in separated mechanical, electronic, control and informational domains. The first guideline in mechatronics was VDI-2422 (VDI, 1994) intended for contemporary microcontroller based systems, where mechanical structure, circuit layout and software were developed separately, with no interdisciplinary linkage during embodiment design phase. This was overcome by a domain integration approach defined in VDI-2206 (VDI, 2004), which declares a V-model of systems engineering as a development approach in a multi-disciplinary development environment with inter and cross-domain interaction and concurrent approach. This trend towards more complex products also puts impact on more sophisticated management of product development processes. Resolution of conflicts and interferences among them became critical in such environment.

Yet another important viewpoint is a product from its life cycle perspective. The recent advances of information technology radically changed the way product development is done. First breakthrough was achieved by CAD tools, especially by 3D modellers, which made possible effective geometric and product data generation and exchange. There would not have been any modern product development without various technical information systems like CAE, PDM and CAM, ERP and PLM which facilitate to a high extent data flow of complex digital artefacts in distributed environments. Fig. 3, adapted from (Nieman, Tichkiewitch and Westkämper, 2009), illustrates the complexity of modern product model domain complexity, due to the product life cycle perspective. Such a model is not only about a core product and its characteristics, materials, accessories, but as well about financial aspects, after sales maintenance, product service systems and recycling and safe disposal.

As already stated, a mechatronic system design requires methods, tools and expertise in several engineering fields, namely mechanical, control, electronics engineering as well as various level programming. Since project based organisation of such development is evident, collective competence should be defined, composed of all individual knowledge and experience, necessary for successful implementation of a design task. Variety of tools, methods and “over-informed” staff make recognition of good design choices more difficult and again competence is of vital importance. Therefore, a new design and development paradigm, suitable for growing market demands and coping increasing product and system complexity, should be established. Such an innovative design and development (D&D) structure has been proposed by Peklenik and reported upon in detail in (Peklenik, 2004, 2006) and is resumed here briefly. The D&D process thus starts from a product specification proceeds through the innovative development and design, prototype and manufacturing technology elaboration to a working prototype. Both processes, namely design and prototyping are conducted by specialised engineering teams. Since collected engineering knowledge might be insufficient, additional training should be available. In order to access additional less focused, broader knowledge on design and technology applied and manufacturing research teams are employed. Efficient cooperation of all teams and individuals collaborating in product formation is of crucial importance. In this context a virtual coordination unit (VCU) was developed (Peklenik, 2004), Fig. 4.

The basic tasks of the VCU are a) organisation and management of the data stored in various data and knowledge bases, on different locations; b) maintenance of effective communication, coordination and control of the activities performed by the subjects of various teams and the teams as a whole; c) communication with the innovation management, reporting on every significant aspect in the development and design of the HT-product; various aspects of patent management; d) organisation of additional training courses on-line for the subjects working in development and design prototyping teams; e) survey of the research activities of various research teams at universities, research institutes, companies: manufacturing capacities of the SME participating in the production of HT- products: etc. The term team can as well apply to the OLEO. The VCU-function of coordination and control includes a fast and reliable communication with the manager, various teams and team subjects, the researchers of the in- and outside the R-units, the training bodies, patent office etc. The IT with the Internet and LAN- structures are the most capable means for realization of the virtual coordination function. Whereas the coordination of processes is performed by the virtual coordination unit (VCU), a virtual competence centre (VCC) has been introduced for communication, teamwork and cooperation support (Sluga et al., 2005). It provides communication among team members, teams and VCU. The communication is carried out over the VCC portal. The portal enables access to data and knowledge bases, applications and web services that are intended for common usage. The portal also provides a common electronic workspace in order to support communication and asynchronous cooperation. Contemporary information and communication technologies (ICT) enable different means and methods for e-collaboration. The key requirements for implementation of the D&D collaboration framework are functional and resource integration; synchronous and asynchronous communication; data, file and document management; project management; and common cooperation space in a distributed environment. Besides, the ICT platform should assure a high level of privacy, safety, and reliability.

On-line engineering office

As market circumstances – i.e. growing product complexity and functionality, less predictable market, demands on higher quality, etc. – influence production companies, this reflects design and development as well. So as companies develop organizational forms enabling prompt adaptation and much higher flexibility, similar transformation is necessary in design and development domain. Goals of such an adaptation should be faster response, flexibility, ability to collaborate in a distributed environment, mastering increased complexity, cross-domain collaboration, mastering information flow, improving mutual communication to avoid misunderstandings. D&D tasks in such environment are becoming more complex and more diverging in general; time spans to accomplish such tasks are narrowing.

This also essentially influences organizational structure. In the chapter proposed formation uses an adaptable ad/hoc networked development environment collecting:

– human expertise,

– engineering tools,

– web tools and methods,

– data and knowledge bases, and

– communication and collaboration tools.

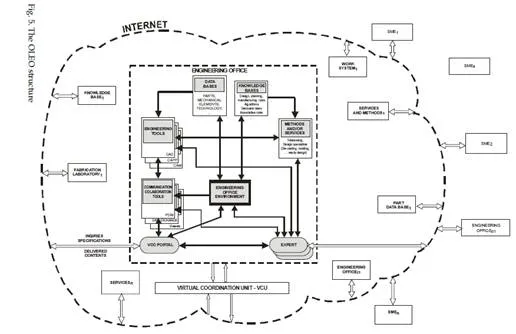

E.g. human expertise is valuable, however, it is very often hidden, it is difficult to discover information even if someone would have paid for it and previously stated environment makes it available. Thus, such an environment, collecting tools and human knowledge and coordination through internet enables better design and development possibilities also for SME. Fig. 4 reveals the structure of the proposed on-line engineering office (OLEO) first proposed during work for European Framework Programme 6 project “Virtual Research Lab for a Knowledge Community in Production) VRL KCiP”, (Peklenik et al., 2008). The general idea of the VRL KCiP is to collect human skills, tools and equipment in a virtual manner and evolved to Emiracle (Emiracle, 2010). The OLEO environment backbone is a VCC portal assuring access to its particular elements Hlebanja et al., 2008, Hlebanja, 2009). Experts, competent professionals, use engineering tools on everyday basis. They also use data bases needed in design process, e.g. parts and assemblies, collected by TraceParts (TraceParts, 2010). Communication and collaboration tools in OLEO are of crucial importance. Rules regarding special design features (die casting, moulding, etc.) could be to some extent part of engineering tools (integrated in CAD systems), however many special methods and knowledge are systemized in additional tools, services or knowledge bases. Supplementary, even competing or complementary tools, services and methods are accessible through internet, as well work systems implementing prototypes and even labs, when experimental research is needed. Production SMEs are usually in the position of customers; they require information, service or finished design. In this context the OLEO could be regarded as a special type ADMS (adaptive distributed manufacturing system) (Sluga et al., 2005), where design assumes the role of a product.

An accomplished project could even result in mutual efforts of several OLEOs, which could be in a long term cooperation or in an ad-hoc connection, some tasks could be even outsourced. The ability of an ad-hoc grouping in a case of necessity is advantageous. There are almost unlimited scenario combinations. However, this is true only, if collected knowledge and experience (i.e. competence) and design process coordination lead to the objective to be accomplished. The OLEO is therefore characterized as a web based on-line accessible engineering facility with sufficient competence and abilities in at least one main engineering development and design area and ability to form or adjoin another corresponding facilities based on their and collected competence. Functionalities then depend on design and development tasks that the OLEO is competent in. Fig. 5 reflects its structure.

Tools

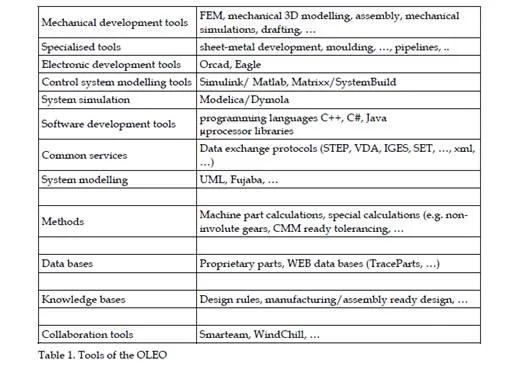

High-tech or mechatronic systems – innovative products in general – development and design require interdisciplinary combination of mechanical, electronic, control and information engineering development in a concurrent manner, so called cross-domain engineering to build the underlying mechanical and electrical structure, and its control and programming environment to accomplish the system integration. Traditional engineering sequences could not result in an optimal solution

Innovation lies prevailingly in early design phases, regardless of the design methodology in use, structured (Pahl&Beitz, 2007, VDI, 2004) or axiomatic design (Suh, 2001), which are basically not fundamentally different (Meijer, 2006). It appears that VDI systematics (VDI,2004) helps to position tools and methods used in product development in a particular spot. Several interacting sub-models should be developed during HT product design already in the principal solution phase:

a. demands,

b. environment

c. target system,

d. working structure,

e. shape,

f. functions,

g. scenarios,

h. working characteristics (e.g. dynamic response, digital logic, etc.) (Krause& Gausemeier, 2007).

Table 1 contains characteristic examples of tools used in the OLEO.

Communication, collaboration and coordination

Communication, collaboration and coordination are essential in an efficient OLEO:

1. communication between engineering office and customer, i.e. SME,

2. collaboration among developers, regardless it is intra- or inter-offices or customers,

3. coordination of development and design project. Means of communication could be categorized in

– asynchronous tools (e.g. mailers, task organizers, file exchange, etc.),

– videoconferencing, web dialogs (e.g. Unyte),

– model visualization tools,

– tools enabling collaborative functional use of a CAD system,

– project oriented collaboration using PDM systems, and

– VCC as access point communication tool.

Collaborative engineering is facing several problems, namely: lack of collaboration tools integration, incompatibility of tools, ad-hoc collaboration, failing standards, data security, etc. Despite that, the collaborative environment is a field with a steep increase rate due to its growing importance. If someone puts search for “virtual collaboration” in Google the response is plentiful. There are free or payable solutions, project management solutions, etc. Communardo (Communardo, 2010) is a company providing appropriate innovative solutions in this field for many years. The VCU in an OLEO gains additional role. The problem is as already said, collaboration. Design tasks are project based and the VCU should coordinate such project in two cases, depending on project ownership.

In the first scenario our OLEO is the project owner and the VCU coordinates:

a. the project as such,

b. all tasks delivered to the owner and

c. all tasks delivered to other entities,

which might be SMEs, another OLEO or manufacturing facilities – autonomous work

systems (Sluga et al., 2005). The opposite scenario is that our OLEO is a contractor of some company, which might also be an OLEO or SME or even LSE. The project owner is the other party in this case, so our OLEO is subordinated. The problem faced here is that each partner

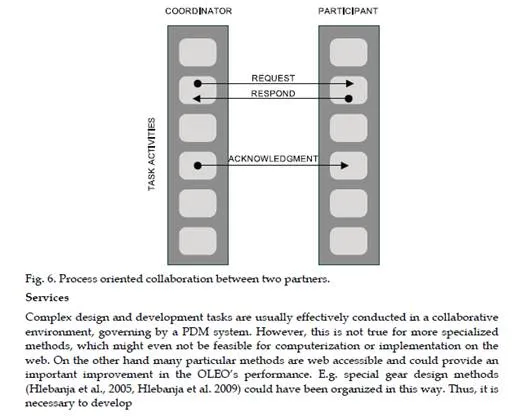

runs his own processes. And at this point there are two possibilities the data or process integration. Regarding the first, the coordination is about how to coordinate data transmission and transformation in such a way that the partner could accurately interpret the data and vice versa. The process oriented collaboration of a particular task is illustrated in Fig. 6. Depending on whether our OLEO is the owner or the subordinated party, it is in the left or right side in the figure. Such, task (process) based collaboration emerges in numerous scenarios, and especially in engineering change management (ECM) processes, which are of particular importance due to design process complexity and iterative procedure. The latter led to VDA recommendation, (VDA, 2010).

When there is a customer/supplier relationship between two partners, there are typically dependencies between the private ECM processes of the individual partners. At different times in the engineering change management process, one of the partners proposes a change or one partner must be integrated in the other partner’s own process in order to permit activities such as technical elaboration, evaluation or decision-making. This is generally achieved by sending suitable messages to the partner (VDA, 2010), as illustrated in Fig. 6. However, the collaborative environment could gain quite complex forms. And the VCU acquires a new role – that is coordination of such processes subordinated to a particular project.

Web services are founded on the Service-Oriented Architecture (SOA). This concept is based on an architectural style that defines an interaction model between three primary parties: the service provider, who publishes a service description and provides the implementation for the service, a service consumer (receiver), who can either use the uniform resource identifier (URI) for the service description directly or can find the service description in a service registry and bind and invoke the service, Fig. 7. The service broker provides and maintains the service registry (Arsanjani, 2004). The registry in a web community is in principle public. However, it should be kept in a domain of the OLEO in this case.

Design scenario

A design scenario is employed as an illustration of the OLEO concept, in this case an automated testing rig for observation of slow speed rolling sliding contacts, developed at the Faculty of Mechanical Engineering in Ljubljana (Hlebanja&Peklenik, 2003). Many heavy duty machines, final stages of power transmissions, etc. incorporate such contacts, which are particular in their properties, possible damage forms, etc. Experimental work contributes to the development of a useful contact model of such processes, thus improving design of such contacts. Normally the D&D process would have been started with the market research, affirming state of the art, market needs and perspectives, continues with specification, in depth iterative (system) development, and a working prototype development (system integration) (Peklenik, 2004, 2006), which also includes product testing, its acceptance and certification (if feasible). Manufacturing technology, assembly and quality control considerations would be also required in case of anticipated serial production (Iserman, 2008).

In this particular case an equivalent to the mechatronic product specification process (Peklenik, 2004) was necessary. The scientific research on feasibility and industrial relevance of such experimentation and its results had to be conducted in the first place. Upon acquired information some decisions could be derived. The consequent pre-project phase aims

a. to define a task specification, and

b. to form a D&D team in which a mechanical designer, electronic engineer and a scientist contribute.

The situation analysis should answer questions regarding experimental conditions. In this early development stage, several aspects, influences and preliminary sub-models should be worked out. These include environmental conditions and influences, experimental strategies (scenarios) elaboration, definition of functional structure and functional units, working structure elaboration, and preliminary shaping (Gausemeier, 2005).

The above analysis implied testing rig boundary conditions, that is

– cylindrical convex-convex rolling-sliding contact,

– speed range according to Stribeck’s curve between 0,035 and 0,2 m/s,

– Hertzian pressure up to 1400 N/mm2,

– experiment duration up to 500 hours (fatigue cycles),

– sliding circumstances, etc.

Consequently, the machine size can be defined, i.e. normal force up to 10000 N. Several aspects were considered afterwards, e.g. long term experiment stability, assurance of automatic and punctual stop in case of damage (scuffing), etc. The result in this phase was redefinition of demands, confirmation of a functional model, experimental scenarios elaboration, etc. Based on above, a so called “semi-operational” scheme was developed, Fig. 8. Based on the pre-project information review and evaluation of expenses it was decided to proceed with the project. The mechanical structure was produced and assembled in an external facility and the machine integration, revival and testing took part prior to final delivery. The testing rig made possible slow speed rolling-sliding contact experiments, thus enabling research on cold scuffing, wear and pitting phenomena. The testing rig was developed using computer tools. Experiments have been controlled and monitored by a computer. However, the development environment was not integrated to the extent prevailing today, communication being physical, by phone or by e-mail and file based.

How could an OLEO benefit to the above or any project?

– First of all there is the necessity for the integrated development environment, which enables better coordination, on-line accessible data, easier communication, etc.;

– the role of the VCU is expanded over the initial tasks defined by (Peklenik, 2004);

– using video-conferencing and visualisation tools for brainstorming, clarifying technical details;

– employing new collaboration tools, e.g. EVO (EVO, 2010), which enable audible and visual communication as well as sketching tools, or Unyte (Unyte, 2010), which makes public the entire desktop;

– less or no transportation time and expenses, and this way ecologically suitable;

– better prepared meetings;

– particular specialists enter D&D process only and if necessary for the time needed to accomplish their task, which is the characteristic of a lean organisation;

– efficient project management;

Conclusion

Conclusion

The need to restructure basic characteristics of emerging design and production systems was exposed in the chapter. The concept of the adaptable and competent network structures for D&D process innovation has been summarized and the role of the virtual coordination unit explained. Furthermore, an on-line engineering office (OLEO) structure has been proposed in order to facilitate distributed development of innovative high tech products and mechatronic systems. The OLEO could be feasible structure for individual entrepreneurs as well as for SMEs. The structure of OLEO has been explored with regard to necessary human expertise, engineering tools, web tools and methods, data and knowledge bases, and communication and collaboration tools. Through the illustrative D&D scenario, the importance of web based integration was pointed out.However, at present time this task appears to be of extreme complexity. Therefore the aim should be narrowing the OLEO domain to a controllable extent. Furthermore, methods capable of implementation as web service should be defined and evaluated, to gain their competence in the OLEO domain.And finally it should be stated, that an OLEO is a step towards a flexible flat organization, where each partner contributes according to his expertise. Thus, in case of a complex project, many contributing partners can combine their competences in order to accomplish the common goal. However, the virtual coordination unit (VCU) should coordinate the project processes. In comparison to research and design departments there is no need to continually assemble an organized form. And tools enabling such virtual enterprises – virtual portals are becoming more and more sophisticated each day. Activities like interpreting and proofreading can already fully rely in virtual platforms. Importance and potential of such “virtual” organization has also been widely recognized in several European FP6 projects, e.g. already mentioned VRL KCiP, which recently transformed to Emiracle (Emiracle, 2010). The flexibility of an OLEO and its ability to use resources in a lean manner and wisely makes it feasible also in sustainable product development and disposal.