|

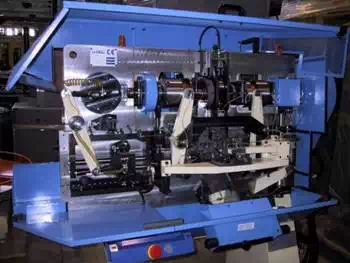

| PGU 250 – MECHANICAL MULTI SLIDE BENDING MACHINES OMCG is proudly manufacturing mechanical multi slide bending machines like the PGU series since 1963. Still today multi slide machines are the best choice for when it is required high productivity rates at 2400 – 12000 pph. Along the years OMCG also introduced the TRG series of multi slide forming and blanking machines. The accurate, repeatable, and powerful multi slide forming machines can be used to produce parts economically, at much lower cost than those manufactured for example with power presses. Complex forming operations that add cost to progressive tooling, can be formed easily on a multi slide machine with substantially less expensive tooling.Multi slide technology can be an extremely competitive method for manufacturing specific parts, particularly wire and strip forms such as medical devices, wire formed clamps, retention spring clips, spring stoppers, pail handles, strikers, clutch springs, etc. Multi slide bending machines also have better productivity than other more expensive radial wire/strip bending machines. OMCG’s multi slide bending and forming machines features up to 12 slides and their great advantage is the ability to make the complete part start to finish with high output rate and unmatched stability and repeatability.PGU250 multislide forming machine provides secure and efficient running with a wide variety of complex forming operations. The availability of up to 8 bending slides, 4 rear motions and a wide range of options like for example: 6 ton press; welding, threading, chamfering and punching units; extra feeder; numerical controlled feeder, allow this model to satisfy the most demanding requirements. The famous reliability of OMCG machines is assured by the use of the highest quality components and materials, but above all, by our customers, operating them efficently for over 40 years. APPLICATION EXAMPLES:coat hanger hooksbucklesspring hose clampshandles |