The objects that generate magnetic field are known as magnets. The force field developed will either pull or repels with materials as nickel and iron. The attracted forces pull the Ferro magnetic materials as iron. All the magnets are not made of same elements. These magnets are classified on the basis of the elements in them.

Types:

- Permanent magnets:

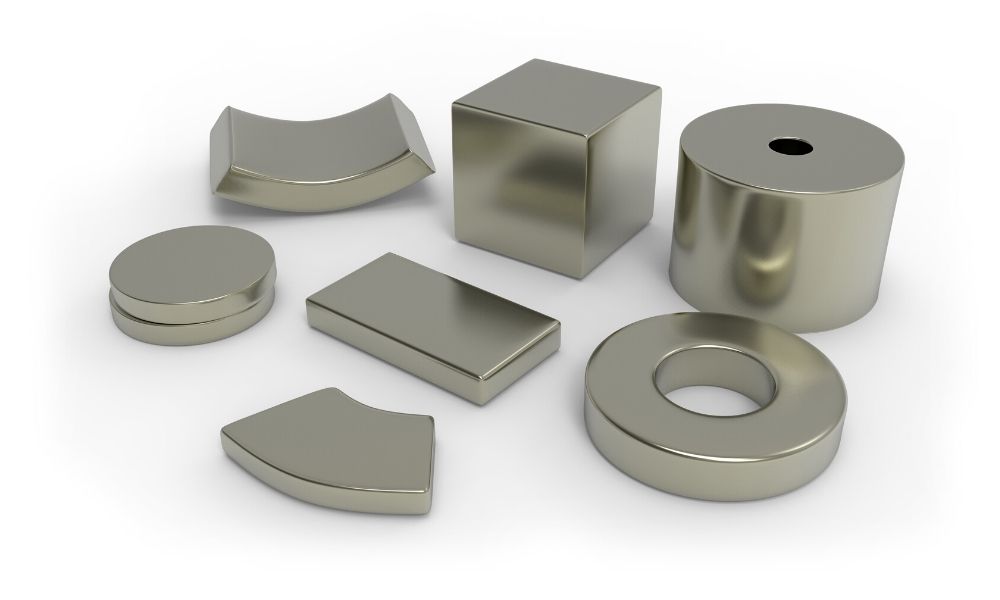

These are the type of magnets that attain permanent magnetism when once magnetized. These are the common types of magnets that we come across in our daily life. The permanent magnets are generally made of Ferro magnetic materials. The atoms and molecules in the material will be positioned in order to reinforce each other. There are four types of permanent magnets:

- Neodymium iron boron (NdFeB): The rare earths magnetic materials form the composition to these magnets that has high energy and coercive force. The energy level is upto 50MGOe. These are generally manufactured in compact and small sizes. These are durable magnets and find difficulty to demagnetize them. The induced cost is high with low mechanical and brittle strengths. The temperature stability is very low. When the magnetic is uncoated it has very low corrosive resistance.

- Samarium Cobalt(SmCo): These magnets have similar properties like NDFeB as strong magnetism. It has high oxidation and temperature resistance. With respect to energy this magnet type is subdivided into first and second series as 15-22 and 22-30 MGOe. The cost that is induced is very high and this magnet lacks in the mechanical strength (brittle nature).

- Alnico: This magnet name comes from the initial letters of the main ingredients in it as aluminum, nickel and cobalt. These magnets can be easily demagnetized even though they possess good thermal resistance. These magnets are produced by casting or by sintering. Each process of their preparation yields different properties to the material. Mechanical traits are prepared by sintering process whereas the casting will result in high energy products. Casting processing of magnets will enable an easy preparation of any complicated design feature.

- Ceramic or Ferrite: Sintered iron oxide and barium or strontium carbonate are the components of ceramic type and these are generally inexpensive and can be easily produced. A diamond wheel grinding is required in their preparation. These possess high corrosive resistance, high mechanical strength and high temperature stability. The investment in its production is very high with low corrosive as well as low energy in the product. These have strong magnetic properties and cannot be easily demagnetized.

Temporary magnets:

Temporary magnets vary with respect to their composition. These act as permanent magnets in strong magnetic fields. These are quite opposite to the permanent magnets as they lose magnetism when taken out form the magnetic field. Iron nails, paper clips are examples of such temporary magnets. These are generally used in telephones and electric motors, in soft iron devices.

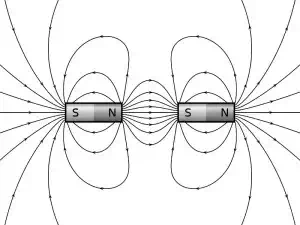

Electro magnets:

Electro magnets are made by winding a wire around a core material into multiple loops. Such formation is termed as solenoid. In order to create magnetic field and magnetize this solenoid an electric current sent as an input. The magnetic file is strong inside the coil and the field strength is proportional to the number of loops in that coil. The core is generally composed of Ferro magnetic material and therefore the magnet strength will increase drastically. These types of magnets are used in large cranes that are used to lift cables and other construction rods. If the current supply is stopped then the core gets automatically demagnetized.

Super conductors:

These are the strongest magnets. These magnets do not require any core but these are made of coils. These types of magnets are made of special type of metal alloys that form super conductors when they are cooled at very low temperatures.

Applications:

- Magnets are most often used industrial appellations as sweepers, sorters.

- These are used in the separation of the impure materials from metal manufacture process.

- Magnets are used in electronic devices as televisions, speakers, video tapes, radios and telephones.

- Permanent magnets are used in the magnets of refrigerators, jewelry preparation.

- The temporary magnets are used in the applications that require the magnetic response for a certain period of time.