This article is based on the basic concept of ISO System of tolerance. We will discuss fundamental deviation, fundamental tolerance, and the calculation of tolerance according to the symbol used.

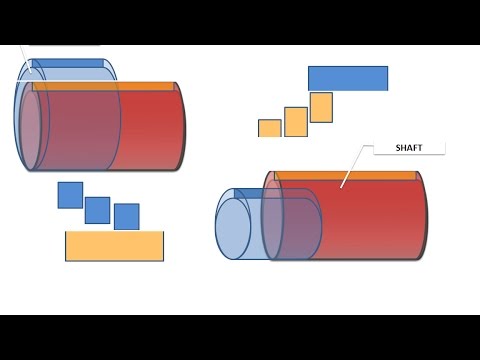

Based on the ISO system of limits and fits of 1940, ISO Tolerances for holes and shafts is the most modern and most effective system as compared to others. In this system, sizes of holes are represented by capital letters and shafts are represented by small letters. This system is developed only for general use, and it shows a few unilateral holes and enough range of shafts.

The system lists a full range of 28 holes and 28 shafts. These ranges cover all sizes of shafts and holes. Due to this, this system is more effective and useful than other systems of fundamental tolerance. In numerical form, the tolerance size is defined by its basic value followed by a symbol. The symbol is composed of a letter and a number as well. A fit is designated by basic size which is common to both component, i.e. shafts and holes. That basic size for fit is represented by a symbol corresponding to each component, with the hole being placed first.

Fundamental Tolerance

The tolerance unit is divided into two parts denoted by two symbols, which consist of a letter symbol and a number symbol. This symbol is also known as the Grade.

Features of Letter Symbol

The letter symbol denotes the deviation of actual size from the basic size. The deviation designated by the letter is also known as fundamental deviation. The letter symbol shows the closeness of the tolerance zone to the basic size.

Features of Number Symbol

The number symbol represents the zone of tolerance with respect to the grade of manufacture. This symbol is responsible for the grade of manufacture designed by International Grade, IT, and the tolerance represented by the number symbol is known as fundamental tolerance.

Calculation of Fundamental Tolerance

In the way of calculation of fundamental tolerance and fundamental deviation, this system specifies 13 main diameter systems and 22 intermediate steps. The entire calculation is totally dependent upon the geometric mean D of the extreme diameter of each step.

It provides 18 grades of tolerance IT01, IT0, IT1, IT2, IT3, to IT16. The value of standard tolerance for grades 5 to 16 are determined from the tolerance unit ‘i’ and formula is given below-

i= 0.433 √D + 0.001D mm

Where, D is in mm.

The standard tolerance corresponding to IT01, IT0 and IT1 are calculated by formula given below-

IT01=0.3 + 0.008D

IT0 = 0.5 + 0.0012D and

IT1 = 0.8 + 0.20D

The value of IT2, IT4 are determined between IT1 and IT5 values, geometrically.

Concept of Fundamental Deviation

The symbols of fundamental deviation for holes are A, B, C, D, E, F, G, H, JS,J, K , L, M, N, P, R, S, T, U, V, X, Y, Z, ZA, ZB, ZC. The rest of the letters, i.e. I, L , O, Q, and W, are not used. For shafts the same symbols are used but in lower-case letters.

Fundamental deviation for holes

For holes of symbol among A to H, the lower deviation is above zero line, with lower deviation for hole H being zero. For holes having symbol among J to ZC, it is below zero line. In simple words, we can say that the lower deviation for holes A to H is the fundamental deviation and for holes J to ZC the fundamental deviation is the upper deviation.

Fundamental deviation for shafts

For shafts, the concept of fundamental deviation is opposite to holes. For shafts a to h, the upper deviation is below zero line and having the upper deviation being zero for shaft h. For, shafts having symbol in between j and zc, it is above zero line, i.e. the fundamental deviation for shafts a to h is the upper deviation and for shafts j to zc, it is lower deviation.

Let me show you a few examples of these symbols:

50H8/g7 or 50H8-g7, 40H7-g6

In these examples, 50 and 40 are the basic sizes. The symbol represents the fundamental deviation for holes and small letter ‘g’ represents the fundamental deviation for shaft. The numeric symbols represent the fundamental tolerance. You can get the table of ISO tolerance on the web as well as in the market and in some books, too. You just find the values of fundamental deviation and fundamental tolerance using those tables according to the symbol given. Now, we can easily calculate the actual size of shaft and hole only by small addition and subtraction.

There are a number of combinations of shafts and holes that may be used for a fit. It is better to select hole basis fit. Because it is better as the production of shafts to the required size is easier. But, the shaft basis system is very good for manufacturing bright drawn bars.