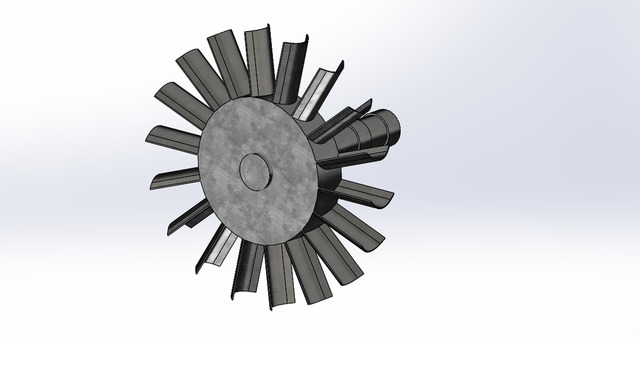

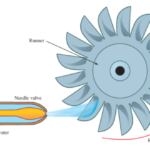

In principle, the impulse steam turbine consists of a casing containing stationary steam nozzles and a rotor with moving or rotating buckets.

When the steam passes through the stationary nozzles and is directed at high velocity against the rotor buckets. The rotor buckets starts to rotate at high speed.

Events take place in the nozzle

· The steam pressure decreases.

· The enthalpy of the steam decreases.

· The steam velocity increases

· The volume of the steam increases.

In nozzles, the pressure energy of the steam is converted into kinetic energy. They are two types of nozzles used in the steam turbine. They are

1. Convergent nozzles

2. Convergent -divergent nozzles

The Convergent Nozzles

They are used for smaller pressure drops where the minimum exit pressure is 0.577 x the inlet pressure (the critical pressure for nozzles.) If the exit pressure is less than 0.577 x inlet pressure, eddy-currents are developed and finally, the exit velocity will be less than calculated.

The Convergent-divergent Nozzles

The convergent-divergent nozzles prevent eddy currents and the calculated velocity will be obtained even at large pressure drops.

The purpose of the bucket or moving blade on the rotor is to convert the kinetic energy of the steam into mechanical energy. If all kinetic energy is converted the steam exit velocity will be 0 m/s. This is not possible but it shows that the rotor blades must bring the steam exit velocity near 0 m/s.

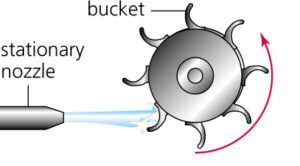

The Impulse Principle

The steam at high pressure enters through a stationary nozzle of a steam turbine, as a result the pressure of the steam is decrease and an increase in steam velocity. As a result of increased steam velocity steam pass through the nozzle in the form of a high-speed jet. This high-velocity steam hit the properly shaped turbine blade, as a result, the steam flow direction is changed. The effect of this change in direction of the steam flow will produce an impulse force. This force cause the blade move, thereby the rotor will start to rotate.

The force applied to the blade is developed by causing the steam to change the direction of flow (Newton’s 2nd Law – change of momentum). The change of momentum produces the impulse force.