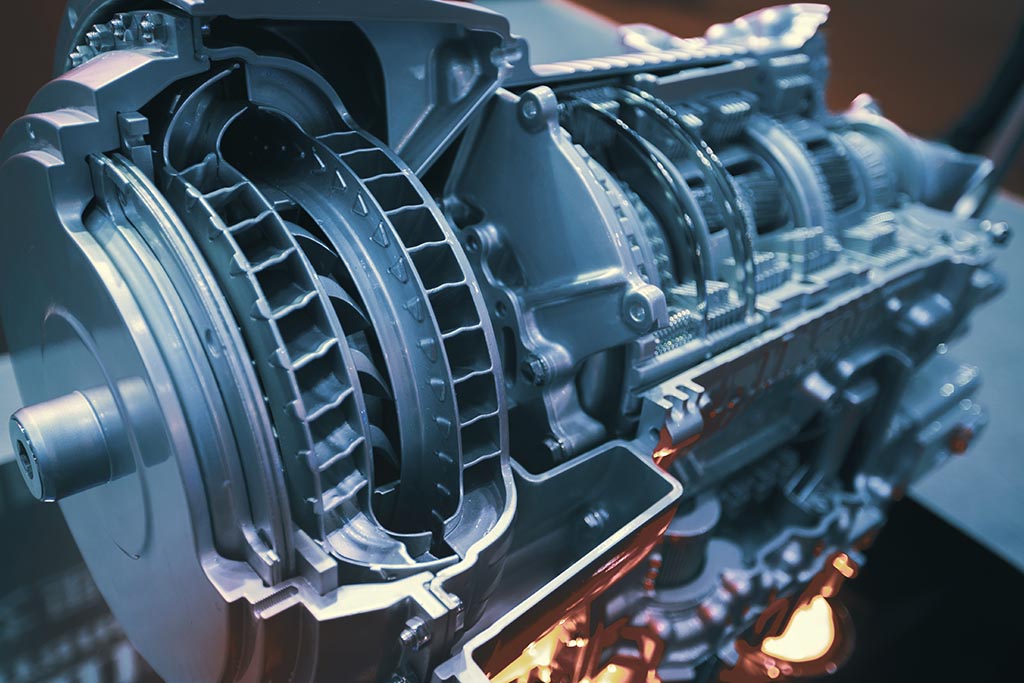

Double-clutching is a driving technique solely used in manual transmission vehicles. Double-clutching was common in older cars and is still common in some modern Race Cars. To understand how it works, the most important thing to know is that there are three systems involved: the engine, the clutch, and the transmission. Your engine produces power, the clutch transmits that power to the transmission, and the transmission sends the power to driven wheels. Each one of these systems, the engine output shaft, the clutch, and the transmission output shaft, can all rotate independently.

The purpose of a clutch is to act as a buffer between the engine and transmission, so when the speeds are mismatched, the clutch is utilized to sync the two systems together. The rotation speed of the transmission output shaft, the shaft that’s sending power to driven wheels, however, is dependent on what gear the transmission is in. In lower gears, the engine will spin fast relative to the transmission output shaft. In high gears, the transmission output shaft will spin quickly relative to the engine.

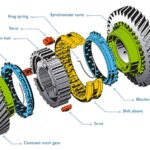

So what does all of this have to do with double clutching? To understand, let’s assume we’re currently in fourth gear, we’re slowing down, and we need to downshift into third gear. As mentioned, this means we’ll be shifting the engine to a higher RPM relative to the vehicle speed. Here’s where understanding the independent role of each system is critical. When you press in the clutch to downshift, the engine rotates by itself, while the clutch and transmission output are still rotating together. As you move the gearshift from fourth, to neutral (before reaching third gear), now the clutch and transmission are rotating separately. Double clutching means at this point, you release the clutch, while the transmission is still in neutral. Releasing the clutch pedal links the engine and clutch together, but the transmission output shaft is rotating faster, as it’s connected to the driven wheels.

In order to successfully shift into third gear, at this point you must raise the engine RPM by pressing the accelerator pedal, raising the rotation speed of the engine, clutch, and third gear (which is indirectly connected to the clutch) to the same speed as the transmission output shaft. Next, the clutch is depressed, the gear selector is moved from neutral to third, and then the clutch is released, all of this providing a smooth downshift.

Recapping the process, downshifting from fourth to third: 1. Press in the clutch pedal. 2. Place the shifter in neutral. 3. Release the clutch. 4. Tap the throttle. 5. Press in the clutch pedal once more. 6. Place the shifter into third gear. 7. Release the clutch pedal.