Introduction

Steam turbines are at the heart of modern power generation. They have been instrumental in converting thermal energy from steam into mechanical energy, which is then used to generate electricity. This article explains the working principles of steam turbines, their components, and their role in power plants.

What is a Steam Turbine?

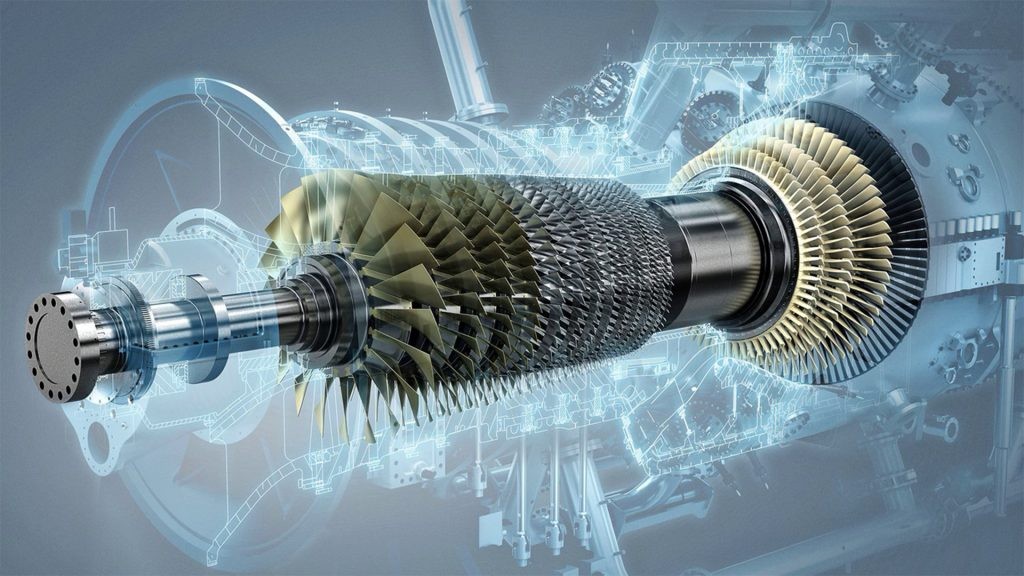

A steam turbine is a mechanical device that extracts energy from high-pressure, high-temperature steam and converts it into rotational energy. This rotational energy is used to drive a generator, producing electricity. Steam turbines are widely used in thermal power plants, nuclear power plants, and industrial applications.

Key Components of a Steam Turbine

- Rotor: The rotating part of the turbine, connected to the generator.

- Blades: Attached to the rotor, blades help extract energy from the steam.

- Casing: Encloses the turbine, ensuring that steam flows in a controlled manner.

- Nozzles: Direct high-pressure steam onto the blades at specific angles.

- Bearings: Support the rotor and allow it to spin smoothly.

- Condenser: Cools down used steam to convert it back into water.

Working Principles of Steam Turbines

Steam turbines operate on the principle of thermodynamics, specifically the Rankine Cycle. Here’s how they work:

- Steam Generation

High-pressure, high-temperature steam is generated in a boiler by heating water. - Steam Expansion

The steam is directed through nozzles, where its pressure energy is converted into kinetic energy. The high-velocity steam then strikes the turbine blades. - Energy Transfer

The kinetic energy of the steam is transferred to the turbine blades, causing the rotor to spin. The rotational energy of the rotor drives the attached generator. - Steam Exhaust

After passing through the turbine, the low-pressure steam is sent to a condenser, where it is cooled and condensed back into water. This water is then recycled to the boiler.

Types of Steam Turbines

- Impulse Turbines

In impulse turbines, steam expands completely in the nozzles, and the high-velocity steam strikes the blades. These are ideal for high-pressure applications. - Reaction Turbines

In reaction turbines, the steam expands both in the nozzles and as it flows over the blades. This type provides smoother energy transfer and is used in low-pressure stages.

Applications of Steam Turbines

- Power Generation: Used in thermal, nuclear, and geothermal power plants.

- Industrial Processes: Drives equipment like compressors and pumps.

- Marine Applications: Powers propulsion systems in ships.

Advantages of Steam Turbines

- High efficiency in converting steam energy into mechanical energy.

- Can operate at very high temperatures and pressures.

- Reliable and capable of handling large-scale power demands.

Challenges and Maintenance

While steam turbines are efficient, they require regular maintenance to prevent issues like blade erosion, thermal stress, and vibration. Advances in materials and design have significantly improved their durability.

Conclusion

Steam turbines remain a cornerstone of global power generation. Their efficiency, scalability, and reliability make them indispensable in meeting the world’s energy demands. Understanding their working principles highlights the intricate engineering behind this technology and its vital role in powering modern society.