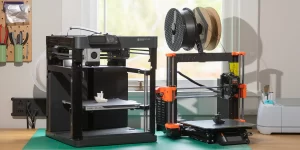

3D printing, also known as additive manufacturing, has transformed the world of manufacturing and product development. Once limited to prototyping, 3D printing has rapidly advanced, making its way into full-scale production, specialized manufacturing, and even home use. With each new development, 3D printing continues to push the boundaries of what’s possible, enabling engineers, designers, and manufacturers to bring their concepts to life faster, more efficiently, and with less waste.

This article delves into the latest advancements in 3D printing, its impact on prototyping and production, and the future of this transformative technology.

The Evolution of 3D Printing

Initially developed in the 1980s, 3D printing technology was first used for rapid prototyping. The early machines were slow and limited in terms of materials and applications. Today, 3D printing has evolved to include a wide range of materials, such as metals, ceramics, and composites, along with precision techniques that allow for intricate, functional designs.

Modern 3D printing technologies now offer a suite of capabilities that rival, and sometimes surpass, traditional manufacturing. This evolution has broadened 3D printing’s applications across various industries, from automotive to healthcare and aerospace.

Key Advancements in 3D Printing Technology

Several recent advancements have expanded 3D printing’s capabilities and applications:

1. Multi-Material Printing

One of the latest breakthroughs in 3D printing is multi-material printing, allowing manufacturers to print complex objects made of different materials in a single pass. This advancement enables the creation of more intricate designs that combine materials with different properties, such as flexibility, rigidity, or conductivity.

- Applications: Medical devices, wearables, and aerospace components that require varying material properties in one component.

- Impact: Reduces assembly time, enables complex designs, and allows for the integration of diverse functionalities in a single print.

2. Metal 3D Printing

Metal 3D printing, or direct metal laser sintering (DMLS), has transformed 3D printing from a prototyping tool to a viable method for manufacturing end-use parts. With metal 3D printing, industries can produce parts with high strength and durability that meet rigorous standards.

- Applications: Aerospace, automotive, and medical implants.

- Impact: Offers an alternative to traditional metal manufacturing, reducing waste and allowing for lighter, customized parts.

3. High-Speed Printing

Speed has always been a limitation in 3D printing, especially when compared to mass-production methods. However, new advancements in high-speed 3D printing, such as continuous liquid interface production (CLIP) and selective laser sintering (SLS), are dramatically reducing production time.

- Applications: Short-run manufacturing, automotive, and consumer products.

- Impact: Reduces time-to-market, enabling rapid prototyping and quicker production of finished products.

4. Large-Scale 3D Printing

Recent advancements have enabled 3D printers to produce large objects and components, from car parts to entire buildings. Large-scale 3D printing uses specialized machines and materials to build objects several meters in size.

- Applications: Construction, aerospace, and automotive.

- Impact: Opens up possibilities for creating large structures quickly and with reduced labor, minimizing construction waste and improving project timelines.

5. Bioprinting and Medical Applications

Bioprinting is an emerging branch of 3D printing that uses living cells to print tissues, organs, and medical implants. While it’s still in its early stages, bioprinting is advancing rapidly, offering promising applications in regenerative medicine and healthcare.

- Applications: Tissue engineering, organ printing, and customized implants.

- Impact: Potential to revolutionize healthcare by providing tailored medical solutions and reducing the need for organ transplants.

6. Sustainable 3D Printing

As industries aim to reduce their environmental impact, 3D printing has adapted with sustainable practices. New techniques allow for the use of recycled materials, biodegradable filaments, and reduced waste, making 3D printing a more eco-friendly option.

- Applications: Consumer goods, packaging, and sustainable architecture.

- Impact: Supports a circular economy by enabling recycling, reducing waste, and using sustainable materials.

7. Improved Surface Finish and Precision

Recent advancements have led to significant improvements in surface finish, detail, and precision. Techniques like stereolithography (SLA) and selective laser sintering (SLS) produce smoother finishes, making 3D printed objects suitable for consumer-ready products.

- Applications: Consumer electronics, jewelry, and automotive parts.

- Impact: Allows for high-quality, aesthetically pleasing products that can be used directly after printing or with minimal post-processing.

How 3D Printing is Revolutionizing Prototyping

Prototyping is one of the primary applications of 3D printing, as it enables designers to rapidly turn digital models into physical objects. This process has seen remarkable improvements:

- Speed and Cost Efficiency: With 3D printing, prototypes can be produced within hours rather than weeks, drastically reducing development costs.

- Design Flexibility: Engineers can test multiple designs and iterations with minimal cost, improving the final product’s quality.

- Risk Reduction: Early-stage prototypes reveal design flaws that can be addressed long before final production, saving time and resources.

- Case Study: In the automotive industry, companies use 3D printing to create prototypes for everything from gear systems to body panels, enabling them to test and refine designs faster than traditional methods would allow.

Applications of 3D Printing in Production

Beyond prototyping, 3D printing is now a viable method for producing final products and specialized components. Here’s how it’s changing various industries:

- Automotive: Car manufacturers use 3D printing for customized parts, lightweight components, and tooling. Porsche, for example, uses 3D printing to produce rare spare parts for classic cars.

- Aerospace: Aircraft manufacturers like Boeing use 3D printing for lightweight, high-strength parts, helping reduce fuel costs and improve aircraft efficiency.

- Healthcare: Custom prosthetics, implants, and even medical instruments are now produced with 3D printing, tailored to each patient’s unique specifications.

- Consumer Goods: 3D printing enables the customization of products, from sneakers to jewelry, providing brands with the ability to meet individual customer preferences.

Benefits of 3D Printing in Production

The widespread adoption of 3D printing in production offers several key advantages:

- Customization: Products can be tailored to individual specifications without expensive retooling or setup changes.

- Reduction of Waste: Additive manufacturing uses only the material required for the object, reducing waste compared to subtractive methods.

- Reduced Lead Times: Faster production times allow for on-demand manufacturing and reduced inventory requirements.

- Design Complexity: Complex geometries that are challenging or impossible with traditional methods can be easily produced with 3D printing.

Challenges of 3D Printing in Full-Scale Production

Despite the benefits, 3D printing also presents challenges that need to be addressed for widespread adoption in full-scale production:

- Material Limitations: Although options are growing, materials suitable for 3D printing remain limited, particularly for high-stress or high-temperature applications.

- Production Speed: While improving, 3D printing is still slower than traditional mass-production techniques like injection molding, making it less viable for high-volume production.

- Quality Control: Achieving consistent quality with 3D printing can be challenging, requiring advanced monitoring systems and post-processing to meet industry standards.

- Cost: High-quality 3D printers and materials can be expensive, which may limit their use in certain industries or applications.

The Future of 3D Printing in Prototyping and Production

The future of 3D printing looks promising, with research and development pushing the technology towards faster speeds, greater material diversity, and broader applications. Key trends to watch include:

- Automation Integration: The integration of 3D printing with robotic systems and automation will streamline production, making it more viable for large-scale manufacturing.

- Distributed Manufacturing: As 3D printing becomes more accessible, companies will establish local “micro-factories” to print parts on demand, reducing shipping costs and carbon footprint.

- Material Innovation: Ongoing research aims to develop new materials, such as bio-based filaments, conductive polymers, and recyclable composites, expanding 3D printing’s applications.

- Hybrid Manufacturing: Combining 3D printing with traditional manufacturing techniques can offer the best of both worlds, enabling high precision and mass production alongside custom, complex components.

Conclusion

3D printing is no longer just a tool for prototyping; it’s revolutionizing production across multiple industries. From rapid prototyping to full-scale production of custom and complex parts, 3D printing empowers manufacturers to innovate quickly and efficiently. With continued advancements, 3D printing will become even more integrated into mainstream manufacturing, transforming traditional processes and opening up new possibilities for product design, customization, and efficiency.

As the technology matures, 3D printing will continue to reshape the landscape of prototyping and production, giving engineers and designers the freedom to explore, experiment, and ultimately deliver better products to the market.