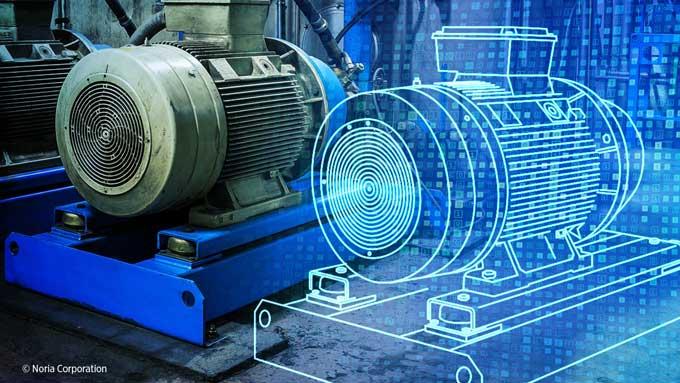

As the world embraces Industry 4.0, digital twins have emerged as a powerful tool in mechanical engineering, revolutionizing how engineers approach design, production, and maintenance. By creating virtual replicas of physical systems, digital twins enable engineers to simulate, monitor, and optimize processes in real-time. This technology has applications across various industries, from aerospace to manufacturing, providing engineers with data-driven insights that drive efficiency, reduce downtime, and improve product lifecycle management.

In this article, we’ll explore what digital twins are, their core components, applications in mechanical engineering, and the future potential of this transformative technology.

What is a Digital Twin?

A digital twin is a virtual representation of a physical asset, process, or system that mirrors its real-world counterpart in real-time. This digital replica is created using data from sensors and other data sources to replicate the performance, behavior, and conditions of a physical asset. By continuously updating itself based on real-world data, a digital twin allows engineers to simulate scenarios, predict outcomes, and optimize processes.

Digital twins rely on a range of technologies, including the Internet of Things (IoT), artificial intelligence (AI), and data analytics. These tools make it possible to monitor and analyze data on the fly, providing engineers with real-time insights into asset performance, health, and maintenance needs.

Core Components of a Digital Twin

Creating a functional digital twin involves several key components:

- Sensors and IoT Connectivity: Sensors attached to the physical asset gather real-time data, such as temperature, pressure, vibration, and performance metrics, and transmit this information to the digital twin.

- Data Analytics and AI: Advanced analytics and AI algorithms process the raw data to provide actionable insights, identify patterns, and even predict future events.

- Simulation and Modeling Software: Simulation software creates a virtual model that behaves like the physical asset, allowing engineers to test different scenarios and optimize performance.

- Cloud Computing and Storage: Cloud-based infrastructure stores and processes large volumes of data, making it accessible for analysis and reporting.

- User Interface (UI): A user-friendly interface enables engineers to interact with the digital twin, visualize data, and conduct simulations.

Applications of Digital Twins in Mechanical Engineering

Digital twins have a wide range of applications across industries, especially in fields where precision, reliability, and efficiency are essential. Here are some of the most impactful applications in mechanical engineering:

1. Predictive Maintenance

One of the primary uses of digital twins is predictive maintenance, where the digital twin continuously monitors an asset’s condition to predict potential failures before they occur. By analyzing patterns and deviations in real-time data, engineers can schedule maintenance at the most opportune times, minimizing downtime and extending the asset’s lifespan.

- Example: In the aerospace industry, digital twins monitor aircraft engines in real-time, predicting potential wear and tear. Maintenance can then be performed before any critical failure, ensuring passenger safety and reducing unexpected downtime.

2. Design Optimization and Prototyping

Digital twins are also valuable during the design and prototyping phases. Engineers can test new designs in a virtual environment before physical production, which reduces development costs and shortens the time to market. The digital twin allows for simulations that reveal weaknesses, inefficiencies, or areas for improvement.

- Example: Automotive companies use digital twins to test new car models for performance and safety features before building physical prototypes. This approach helps them iterate designs and bring optimized products to market faster.

3. Production Line Monitoring and Optimization

In manufacturing, digital twins provide real-time insights into production lines. By simulating production processes and analyzing the impact of changes, engineers can identify bottlenecks, optimize workflows, and increase efficiency.

- Example: A manufacturing plant can use digital twins to simulate different production scenarios, such as varying production rates or introducing new materials. This allows for smoother operations and a reduction in production costs.

4. Asset Lifecycle Management

Digital twins support asset lifecycle management by tracking an asset’s condition over time. From the design phase through production and end-of-life, digital twins provide continuous insights that help manage assets throughout their lifecycle, aiding in decision-making about upgrades, replacements, and decommissioning.

- Example: In the energy sector, digital twins monitor the lifespan of turbines, enabling power companies to decide when to refurbish, replace, or retire each unit based on real data.

5. Real-Time Monitoring and Control

Digital twins provide continuous monitoring, enabling operators to make real-time adjustments and maintain optimal conditions. In complex systems, this capability is invaluable for ensuring stable performance and quick troubleshooting when issues arise.

- Example: In HVAC systems, digital twins monitor conditions and adjust parameters, such as temperature and airflow, for energy efficiency and comfort in real-time.

The Benefits of Using Digital Twins in Mechanical Engineering

Digital twins offer numerous benefits in mechanical engineering:

- Reduced Downtime: By predicting failures and optimizing maintenance schedules, digital twins significantly reduce unplanned downtime.

- Enhanced Efficiency: Real-time insights help optimize processes and streamline production, increasing overall efficiency.

- Lower Operational Costs: Predictive maintenance and optimized resource allocation reduce operational costs.

- Improved Product Quality: Virtual simulations allow for thorough testing and refinement, leading to higher quality products.

- Sustainability: Digital twins help engineers identify energy-efficient solutions and reduce waste, supporting sustainable engineering practices.

Challenges and Considerations

While digital twins offer significant advantages, they also come with challenges:

- Data Security and Privacy: With digital twins relying on real-time data, ensuring data security and privacy is critical, especially in industries like defense or healthcare.

- High Implementation Costs: Building and maintaining digital twins can be costly, particularly for small companies with limited budgets.

- Integration Complexity: Integrating digital twins with legacy systems and existing infrastructure can be complex and time-consuming.

- Data Overload: Digital twins generate large amounts of data, which require advanced analytics to derive meaningful insights. Without proper data management, companies risk data overload.

Future Potential of Digital Twins in Mechanical Engineering

The future of digital twins in mechanical engineering is promising, with several advancements on the horizon:

- AI-Powered Digital Twins: The integration of AI will make digital twins more predictive and autonomous, allowing them to make complex decisions with minimal human intervention.

- Edge Computing: Moving data processing closer to the asset with edge computing will reduce latency, enabling digital twins to deliver insights and responses in real-time.

- Integration with Augmented Reality (AR): AR can enhance the digital twin experience, allowing engineers to visualize virtual models overlaid on physical assets for real-time diagnostics and troubleshooting.

- More Accurate Simulations: As computing power increases, digital twins will offer even more accurate simulations, enabling engineers to model intricate details at a molecular level.

- Cross-Industry Collaboration: Digital twins will become a key enabler for cross-industry collaboration, where different sectors can share insights and practices, driving innovation.

Conclusion

Digital twins are a game-changer in mechanical engineering, offering a virtual bridge to monitor, simulate, and optimize physical assets in real-time. With applications in predictive maintenance, design optimization, and production efficiency, digital twins provide engineers with the tools they need to create more reliable, cost-effective, and sustainable systems. Despite the challenges, the future of digital twins looks bright, with rapid advancements in AI, IoT, and data analytics pushing the technology to new heights.

For mechanical engineers and industries that embrace digital twins, the potential for innovation and operational excellence is boundless, marking a new era in engineering where digital and physical realities converge.