There are two separate types of braking systems that are used within trains. Each of them use a different operating medium and follow through with a unique process in order to bring the vehicle to a complete stop.

The Types Of Brakes That Are Used In Trains:

- Air brakes

- Pneumatic brakes

The two main types of braking systems that are used to stop trains on their tracks are air brakes and pneumatic brakes.

Just like the name suggests, air brakes use the power of air in order to bring the wheels of the vehicle to a complete stop. More specifically, air brake will use compressed air in order to apply pressure to the wheels at the conductor’s demand.

Pneumatic brakes, also known as electro-pneumatic brakes, operate very differently. These types of brakes are electrically controlled, and are generally more thorough than the contrary air braking system.

How Air Brakes Work:

- Compressor component draws air from the atmosphere and compresses it for storage

- Air moves through braking pipe and feed pipe to transport it through the train

- Compressed air travels to the control reservoir

- Air enters into the brake cylinder

- Pushes an interior rod outward

- The rod comes in contact with the brake pad and creates friction, stopping the wheels

Air braking systems are the original methods of braking for trains, and have been used for several years. The main concept of air braking systems is that they use compressed air to put pressure onto the components of the brakes, causing the wheels on the vehicle to come to a complete stop.

To be more specific, there is a large component on the outside of the train that is called the compressor. The compressor draws air from the atmosphere as the train drags along the track, intaking all of the air that it is passing by.

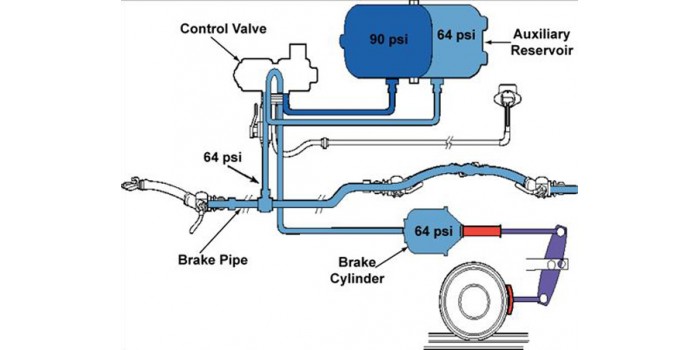

When the air is sucked in by the compressor, it is compressed and compacted before it is stored in a separate area for future distribution. When the operator of the train activates the braking system, the compressed air will move through the braking pipe and feed pipe in order to be transported through the train.

When it gets to the end of these pipes, the air will end up in the control reservoir before it enters the brake cylinder component of the train.

While inside of the brake cylinder, the compressed air will push up against the interior rod that exists within the braking system of the train. This rod is forced into the brake pads next to it, creating friction between the two.

This process will eventually stop the wheels, after applying enough pressure and friction onto the brake pads that ultimately transfers downward to the wheels of the train.

While it is true that air braking systems have proven to be effective in several trains throughout the years, there was still a need for a slight improvement in the functions in order to prevent more error and encourage more effectiveness.

This newer braking system is called pneumatic brakes, or electro-pneumatic brakes. The characteristics of these types of brakes are outlined in the list down below.

How Pneumatic Brakes Work:

- Electronically controlled (but still use air pressure to stop the vehicle)

- Considered a new and improved version of air braking with fewer flaws in function

- Use a mechanical connection to apply pressure to the wheels through the brake blocks

- Compressed air is released into the brake cylinders through triple valves

- Valves are controlled by air pressure from the train pipe (through entire length of the train)

Pneumatic brakes are basically the same thing as air brakes due to the fact that they use compressed air to put pressure on different components of the train’s braking system, only this type of brake uses an electronically wired system to make the process even more streamlined.

When the operator of the train activates the electro-pneumatic brakes, the system uses a mechanical connection to apply pressure to the wheels through the brake block components of the train.

The compressed air is released into the brake cylinders through triple valves, which are controlled by air pressure from the train pipe. The train pipe moves through the entire length of the train and helps to transfer the air pressure through the braking system in order to stop the wheels.

All in all, the electro-pneumatic braking system of a train is essentially the more convenient version of the original air brakes that were previously found in most trains. In the current day, this is actually the most common braking system that you will find in trains all over the world, due to the safety and convenience of use.

As you can see, the brakes that exist in trains are very similar to the ones that you might be familiar with in your car. Using air pressure and electronic wiring in order to apply pressure to the wheels.