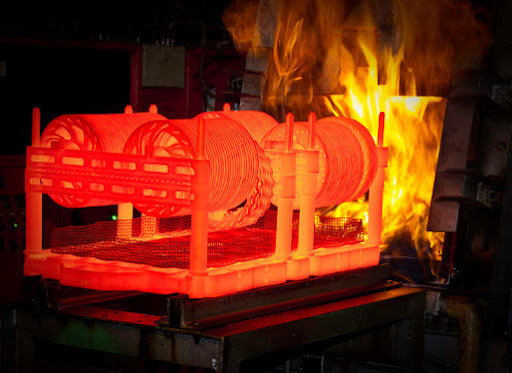

Is used to reduce residual stresses in large castings, welded parts and cold- formed parts. Such parts tend to have stresses due to thermal cycling or work hardening. Parts are heated to temperatures of up to 600 – 650 ºC (1112 – 1202 ºF), and held for an extended time (about 1 hour or more) and then slowly cooled in still air.

Posted inMaterial Science

Stress Relief Anneal

Suresh Kumar is a passionate mechanical engineer with deep expertise in design, thermodynamics, manufacturing, and automation. With years of experience in the industry, they simplify complex engineering principles into practical insights for students, professionals, and enthusiasts. This blog serves as a hub for exploring cutting-edge innovations, fundamental concepts, and real-world applications in mechanical engineering.

Post navigation

Previous Post

Process Annealing

Process AnnealingNext Post

Spheroidization