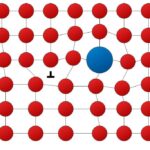

Phenomenon where ductile metals become stronger and harder when they are deformed plastically is called strain hardening or work hardening. Increasing temperature lowers the rate of strain hardening. Hence materials are strain hardened at low temperatures, thus also called cold working. During plastic deformation, dislocation density increases. And thus their interaction with each other resulting in increase in yield stress. Strain hardening (work hardening) is the reason for the elastic recovery. The reason for strain hardening is that the dislocation density increases with plastic deformation (cold work) due to multiplication. The average distance between dislocations then decreases and dislocations start blocking the motion of each one

Posted inMaterial Science

Strain Hardening

Posted by

admin

No Comments

admin

No Comments

Suresh Kumar is a passionate mechanical engineer with deep expertise in design, thermodynamics, manufacturing, and automation. With years of experience in the industry, they simplify complex engineering principles into practical insights for students, professionals, and enthusiasts. This blog serves as a hub for exploring cutting-edge innovations, fundamental concepts, and real-world applications in mechanical engineering.

Post navigation

Previous Post

Solid-Solution Strengthening

Solid-Solution StrengtheningNext Post

Liquid-Penetration test