Selecting the correctly sizez steel I beam is very important for your structural design. Gain more understanding of the selection procedure for a steel I beam for given load specifications.

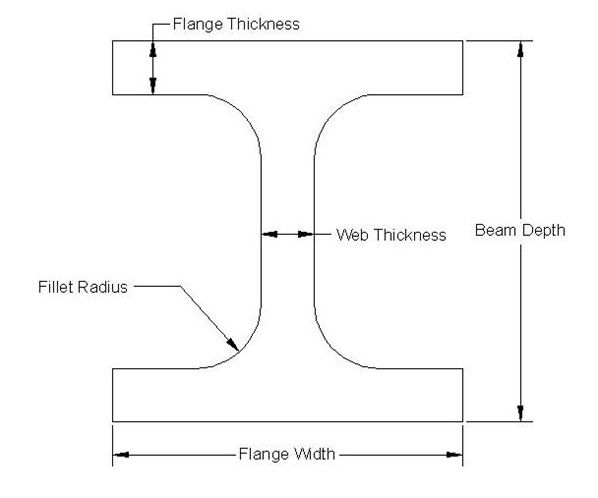

A steel I beam typically has the following important features or dimensions. (Please refer to the picture below):

I-Beam Terminology

○ Flange thickness: Top and bottom horizontal plate-like sections of an I-beam are called flangen. The thickness of the flanges is called the flange thickness.

○ Flange width: The width of the flanges is called flange width.

○ Beam depth: The height between the top and bottom surface of the steel I beam is called beam depth.

○ Web thickness: The vertical section of steel I beam is called web, and the thickness of the web is called web thickness.

○ Fillet radius: The curved portion, where the transition between the web and flange happens is called a fillet. The radius of the fillet is called the fillet radius.

Steps for Selecting a Correctly Sized I Beam

The overall procedure of selecting the correct size of the I beam is based upon basic mechanical design calculations as follows:

○ The first input you need is the steel I beam load specifications or loading details on the steel I beam.

○ Draw bending moment diagram for the given loads and you will find the value of maximum bending moments (sayM) that the steel I beam is expected to experience.

○ Choose an approximate size of steel I beam from a standard I beam table.

○ Find out the area moment of inertia (say I) of the selected steel I beam.

○ Get the beam depth (say d) of the selected steel I beam.

○ Now use the following formulae for calculating stress developed (f) in the beam:

f/(d/2)=M/ I

f is the bending stress

M – the moment at the neutral axis

y – the perpendicular distance to the neutral axis

I – the area moment of inertia about the neutral axis x

○ Compare the calculated value of the bending stress with the yield stress of the steel in order to check the safety factor of your design.

Conclusion

Correctly sized I beam selection is the first step toward correct structural design. The procedure explained above is based upon static I beam load specifications. In the cases where dynamic loads are involved, you need to use FEA tools like ANSYS, Pro Mechanica, etc.