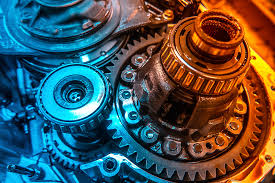

An automatic transmission is a motor vehicle transmission that can automatically change gear ratios as the vehicle moves, freeing the driver from having to shift gears. In this transmission system the gears are never physically moved and are always engaged to the same gears. Automatic transmissions contain mechanical systems, hydraulic systems, electrical systems and computer controls, all working together in perfect harmony manually.

Main Components of an Automatic Transmission–

1. Planetary Gear Sets

2. Clutches and Bands

3. Torque Converter

4. Valve Body

An automatic transmission uses sensors to determine when it should shift gears, and changes them using internal oil pressure. While there are numerous components stuffed into the transmission, and their actual operation is a bit more complicated than the simplified version presented here, the key components are the torque converter and planetary gearsets.

In order to shift gears, the transmission must be temporarily disconnected from the engine. On a manual transmission the driver does that by pushing in the clutch pedal, but on an automatic, it’s handled by the torque converter.

There are two fan-shaped components inside the torque converter, which is filled with transmission fluid: an impeller, which is attached to the engine’s crankshaft, and a turbine, attached to the transmission’s input shaft. As the engine turns the impeller, its blades move the fluid, which in turn causes the turbine to turn. The fluid moves in a closed loop. A third fan-shaped component, the stator, sits between the impeller and turbine and helps direct the fluid’s movement. As you push the throttle to speed up, the fluid moves the turbine faster to send more power through the transmission. As you slow down, the fluid’s movement slows, the turbine stops spinning, and the engine can sit and idle without stalling.

The turbine and impeller aren’t permanently attached, and the impeller always spins faster. Most vehicles use a lock-up converter, which has a mechanical clutch that temporarily connects the two components at higher speeds to help improve fuel economy.

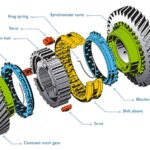

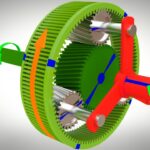

Once that power has been transferred to the transmission’s input shaft, it’s time for the planetary gears to do their thing. The name comes from the way they’re arranged. A central gear is called the sun gear, while smaller planet gears revolve around it, held in a ring called a planet carrier. A large toothed ring gear surrounds them all and is meshed with the planetary gears in their carrier.

Rather than using a separate gear wheel for each gear, the transmission’s various speeds are achieved through combinations of gears. The sun, planetary and ring gears are meshed in various combinations, such as the outer ring gear turning while the inner sun gear stays stationary. This is achieved with small friction clutches, which engage the gears for turning, and bands, which hold them out of the way so they don’t turn. The clutches and bands are operated by pins and valves that are activated by pressurized transmission fluid.