🔍 Introduction

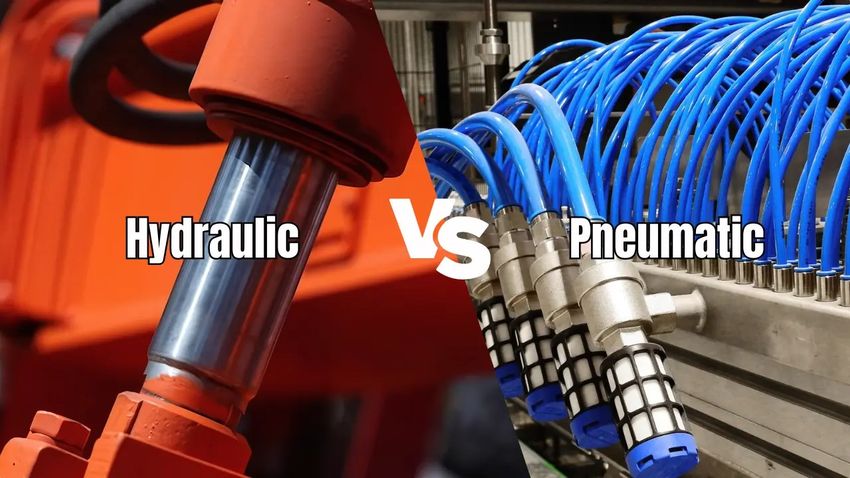

In the world of industrial automation and machinery, motion and force are often powered by fluid power systems. Two of the most widely used types are hydraulic and pneumatic systems. Both rely on the use of pressurized fluids, but they are fundamentally different in how they operate, what they are best suited for, and how they perform in specific industrial applications. ⚙️💧💨

If you’re involved in manufacturing, mechanical engineering, or industrial design, understanding the strengths and weaknesses of each system is essential for choosing the right technology for the job.

💡 Basic Principles

🔵 Hydraulic Systems: Power Through Liquid

Hydraulic systems use incompressible fluids (usually oil) to transmit power. When the fluid is forced through a system of pumps and valves, it exerts force on actuators like pistons or motors.

Key Traits:

-

High power density 💪

-

Smooth, precise control 🎯

-

Heavy-duty industrial use 🏭

🌬️ Pneumatic Systems: Power Through Air

Pneumatic systems use compressed air, which is a compressible gas, to generate movement. Air is pumped into cylinders or motors, creating linear or rotary motion.

Key Traits:

-

Lightweight components 🧰

-

Faster cycling speed ⚡

-

Cleaner and safer in explosive environments 🧯

⚖️ Side-by-Side Comparison

| Feature | Hydraulic Systems 💧 | Pneumatic Systems 💨 |

|---|---|---|

| Medium | Oil or other liquids | Compressed air |

| Power Output | High | Moderate |

| Speed | Slower but more precise | Faster response |

| Force Capability | Very high | Lower |

| System Complexity | More complex and expensive | Simpler and cheaper |

| Maintenance | Requires leak prevention | Easier, but air moisture issues |

| Safety | Risk of fluid leaks/fire | Safer, especially in volatile environments |

| Noise | Quieter | Typically noisier |

| Energy Efficiency | More efficient | Less efficient due to air compression losses |

| Precision Control | Excellent | Moderate |

🏭 Real-World Applications

🔧 When to Use Hydraulic Systems

Hydraulics are ideal in applications where high force and precise control are necessary:

-

Construction Equipment (excavators, bulldozers) 🚜

-

Injection Molding Machines 🧪

-

Hydraulic Presses 🛠️

-

Aircraft Landing Gear ✈️

-

Marine Equipment 🚢

Hydraulic systems excel in heavy-duty environments, especially where power-to-size ratio matters.

🔧 When to Use Pneumatic Systems

Pneumatics shine in environments requiring quick, repetitive motion and a clean operational setup:

-

Packaging Lines 📦

-

Automated Assembly Systems 🤖

-

Dental Tools 🦷

-

Paint Sprayers 🎨

-

Robotic End Effectors 🤖

They are preferred for lightweight, clean, and fast tasks where safety and speed are priorities.

⚙️ Pros and Cons Breakdown

✅ Hydraulics – Pros

-

Handles large loads with ease

-

Precise and controlled motion

-

Operates well under extreme temperatures

-

More energy-efficient at high load

❌ Hydraulics – Cons

-

Risk of leaks and contamination

-

Higher cost and complex maintenance

-

Heavier and bulkier components

✅ Pneumatics – Pros

-

Lightweight and compact

-

Low maintenance requirements

-

Cleaner and safer for sensitive environments

-

Inexpensive components

❌ Pneumatics – Cons

-

Limited force output

-

Less precise compared to hydraulics

-

Noisy operation and energy losses due to air compression

🧠 Decision-Making Factors

1. Required Force and Load

-

If your application demands high force, go hydraulic.

-

For lighter loads and high-speed operations, pneumatics are ideal.

2. Precision and Control

-

Hydraulics offer finer control over motion and positioning.

-

Pneumatics can be less stable due to air compressibility.

3. Cost and Maintenance

-

Pneumatic systems generally cost less up-front and are easier to maintain.

-

Hydraulics have a longer lifespan but require more intensive care.

4. Environmental Concerns

-

Pneumatics are better in clean-room or explosive environments.

-

Hydraulics may pose fire hazards due to flammable fluids.

5. Speed Requirements

-

Pneumatic systems are faster and better suited to high-speed operations like packaging or sorting.

🔮 Emerging Trends

🌱 Eco-Friendly Fluids

New biodegradable hydraulic fluids are being developed to reduce environmental risks. 🌍

🤖 Smart Sensors

Both hydraulic and pneumatic systems are integrating IoT sensors for real-time diagnostics and predictive maintenance. 📡

⚡ Hybrid Systems

Some modern machines combine both systems to take advantage of each. For example, using hydraulics for force and pneumatics for speed. 🔄

✅ Conclusion: Which Is Better?

There’s no one-size-fits-all answer – the best system depends on your specific application needs:

-

Choose hydraulics if you need raw power, precision, and durability in demanding environments. 🏋️♂️

-

Choose pneumatics if you value speed, simplicity, safety, and cost-effectiveness. 🚀

For many industrial applications, the decision boils down to a trade-off between force vs. speed, cost vs. complexity, and precision vs. flexibility.

By understanding the core differences and evaluating your project’s requirements, you can make the most informed decision for your industrial system design. 💡🔧⚙️