Introduction 🌱

Injection molding is one of the most widely used manufacturing processes for mass-producing plastic components. From everyday household items to automotive parts and medical devices, this process is essential for creating durable, cost-effective, and high-quality products. But how does injection molding work, and why is it so popular? Let’s dive into the mechanics, benefits, and real-world applications of injection molding.

What Is Injection Molding? 🤔

Injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape. This method is ideal for producing large quantities of identical parts with high precision and consistency.

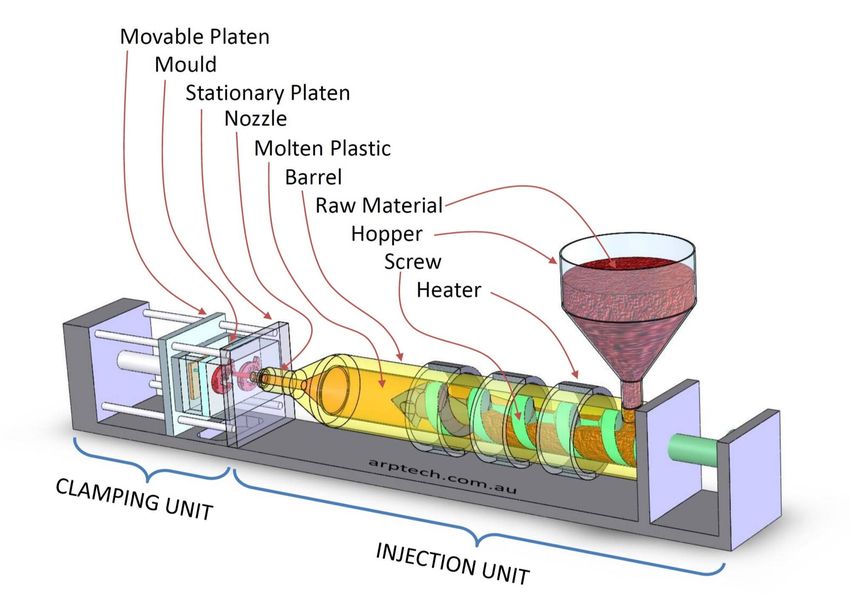

Key components of an injection molding machine include:

- Hopper 📦: Holds plastic pellets that are fed into the machine.

- Heater Barrel 🔥: Melts the plastic pellets into a molten state.

- Injection Unit 💉: Injects the molten plastic into the mold cavity.

- Mold Cavity 🧩: Defines the shape of the final product.

- Clamping Unit 🗜️: Holds the mold halves together during injection and cooling.

- Ejector System 🚀: Pushes the solidified part out of the mold.

How Injection Molding Works: Step-by-Step Process ⚙️

Injection molding involves several key steps, each crucial for producing high-quality components:

1. Material Feeding and Melting 🌡️

Plastic pellets (usually made from materials like polyethylene, polypropylene, or ABS) are fed from the hopper into the heater barrel. The barrel heats the pellets to their melting point, turning them into molten plastic.

2. Injection 💉

The injection unit forces the molten plastic through a nozzle and into the mold cavity at high pressure. This pressure ensures that the plastic fills every part of the mold, capturing fine details and complex shapes.

3. Cooling ❄️

Once the mold cavity is filled, the plastic begins to cool and solidify. Cooling is essential for achieving the desired shape and structural integrity. Cooling time depends on the material used and the thickness of the part.

4. Mold Opening and Ejection 🚀

After the plastic has fully solidified, the mold opens, and the ejector system pushes the finished part out of the mold cavity. The mold then closes, and the process repeats for the next cycle.

5. Post-Processing 🧹

Depending on the application, the finished part may undergo additional processes such as trimming excess plastic, painting, or assembling with other components.

Types of Injection Molding 🗂️

Different types of injection molding processes are used depending on the material, part design, and production requirements:

- Thermoplastic Injection Molding ♻️: The most common process, using plastics that can be melted and reshaped multiple times.

- Thermoset Injection Molding 🔥: Uses plastics that harden permanently after molding, making them heat-resistant.

- Overmolding 🧩: Combines multiple materials or layers in a single part, such as rubber grips on plastic handles.

- Insert Molding 🔗: Embeds metal or other components within the plastic part during molding.

- Micro Injection Molding 🐜: Produces extremely small and precise components for medical devices and electronics.

Materials Used in Injection Molding 🌎

The choice of material depends on the desired properties of the final product, such as strength, flexibility, and heat resistance. Common plastics used in injection molding include:

- Polyethylene (PE) 🧴: Lightweight, flexible, and resistant to moisture.

- Polypropylene (PP) 🚗: Durable, chemical-resistant, and used in automotive parts.

- Acrylonitrile Butadiene Styrene (ABS) 🧸: Strong, impact-resistant, and used in toys and electronics.

- Polystyrene (PS) 🍱: Lightweight, rigid, and used in packaging and disposable products.

- Polycarbonate (PC) 🥽: Transparent, impact-resistant, and used in eyewear and electronics.

- Nylon (PA) ⚙️: Strong, wear-resistant, and used in mechanical components.

Advantages of Injection Molding ✅

Injection molding offers numerous benefits that make it the preferred method for mass-producing plastic components:

- High Efficiency and Speed ⚡: Fast production cycles enable the mass production of large quantities of parts.

- Precision and Consistency 🎯: Produces complex shapes with tight tolerances and consistent quality.

- Cost-Effective 💸: Low production costs per unit, especially for high-volume runs.

- Versatility 🔀: Compatible with a wide range of plastics and composite materials.

- Minimal Waste ♻️: Excess plastic can often be recycled and reused.

- Scalability 📈: Easily scalable from small prototypes to large-scale production.

Challenges and Limitations ⚠️

Despite its advantages, injection molding also has some challenges:

- High Initial Costs 💰: Tooling and mold design can be expensive, especially for complex parts.

- Design Constraints 📏: Mold design must account for factors like shrinkage, warping, and draft angles.

- Material Limitations 🧪: Not all plastics are suitable for injection molding.

- Environmental Impact 🌱: Plastic production and waste can have environmental consequences if not managed responsibly.

Real-World Applications of Injection Molding 🌍

Injection molding is used in virtually every industry to produce a wide variety of plastic components:

- Automotive 🚗: Dashboard panels, bumpers, and interior components.

- Consumer Goods 🏠: Toys, kitchenware, and household appliances.

- Electronics 💻: Housings for smartphones, laptops, and other devices.

- Medical Devices 🏥: Syringes, surgical instruments, and prosthetics.

- Packaging 📦: Bottles, containers, and food packaging.

- Construction 🏗️: Pipes, fittings, and insulation materials.

The Role of Mold Design in Injection Molding 🧩

Mold design is crucial for ensuring the quality, efficiency, and consistency of injection-molded parts. Key aspects of mold design include:

- Cavity and Core Design 🧱: Defines the shape and features of the final product.

- Cooling System ❄️: Ensures rapid and uniform cooling to prevent defects.

- Ejector System 🚀: Facilitates the easy removal of finished parts.

- Venting System 💨: Allows air and gases to escape during injection.

- Material Flow Channels 🌊: Distribute molten plastic evenly throughout the mold.

Molds are typically made from durable metals like steel or aluminum to withstand high temperatures and pressures. Computer-aided design (CAD) software is used to create precise mold designs that optimize production efficiency and part quality.

Quality Control in Injection Molding 🕵️

Maintaining high quality is essential for injection-molded products, especially in industries like automotive and healthcare. Key quality control measures include:

- Dimensional Accuracy 📏: Ensuring that parts meet specified dimensions and tolerances.

- Surface Finish ✨: Checking for defects like sink marks, warping, and flash.

- Material Properties 🧪: Verifying strength, flexibility, and impact resistance.

- Process Monitoring 📊: Using sensors and automation to maintain consistent production conditions.

Environmental Impact and Sustainability ♻️

As environmental concerns grow, the injection molding industry is adopting more sustainable practices, including:

- Recycling and Reusing Plastics 🔁: Using recycled materials to reduce waste and conserve resources.

- Biodegradable Plastics 🌱: Developing eco-friendly materials that break down naturally.

- Energy-Efficient Machines ⚡: Reducing energy consumption through advanced equipment and processes.

- Minimizing Waste 🗑️: Designing molds and processes to reduce scrap and material waste.

These innovations are helping manufacturers reduce their environmental footprint while meeting the demand for high-quality plastic products.

The Future of Injection Molding 🚀

The injection molding industry is evolving rapidly, driven by technological advancements and changing consumer demands. Future trends include:

- 3D Printing and Rapid Prototyping 🖨️: Combining injection molding with additive manufacturing for faster product development.

- Smart Manufacturing and Automation 🤖: Using IoT and AI to optimize production processes and improve quality control.

- Sustainable Materials and Green Manufacturing 🌱: Developing new materials and processes that reduce environmental impact.

- Advanced Mold Designs and Materials 🧩: Creating more complex and lightweight components for industries like aerospace and automotive.

As technology advances, injection molding will continue to play a vital role in producing the plastic components that power our modern world.

Conclusion 🌟

Injection molding is a cornerstone of modern manufacturing, enabling the mass production of plastic components with exceptional precision, efficiency, and cost-effectiveness. By injecting molten plastic into molds, this process can create complex shapes and high-quality parts used in industries ranging from automotive and electronics to healthcare and construction. With ongoing innovations in materials, automation, and sustainability, injection molding is poised to remain a key driver of industrial production for years to come.